Filter frame for digital camera made from polymer elastic body

A polymer elastic body and digital camera technology, applied in the field of filter frames for digital cameras, can solve the problems of camera lens barrel optical axis deviation, poor watertightness of fitting parts, etc., and achieve the effect of improving watertightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

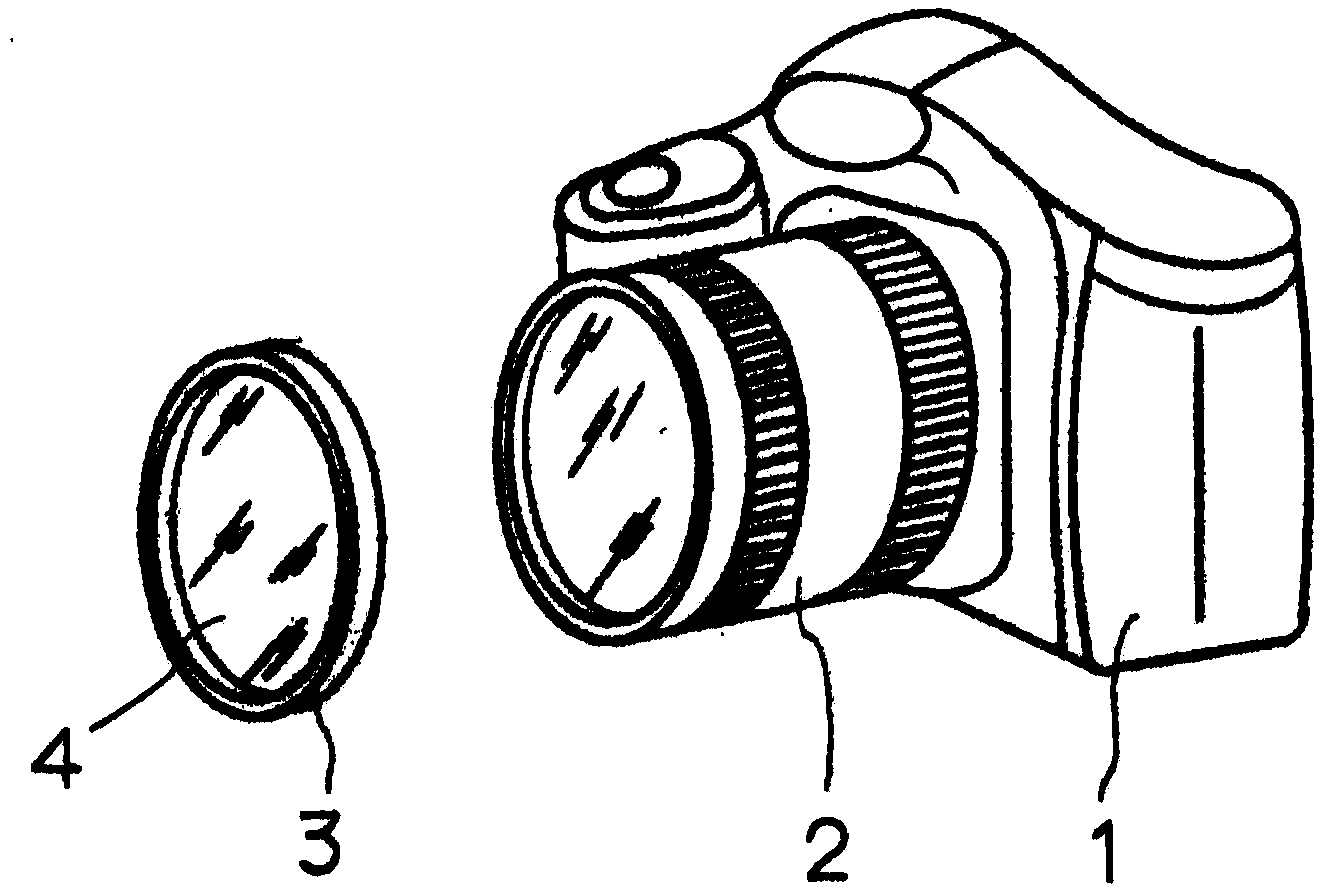

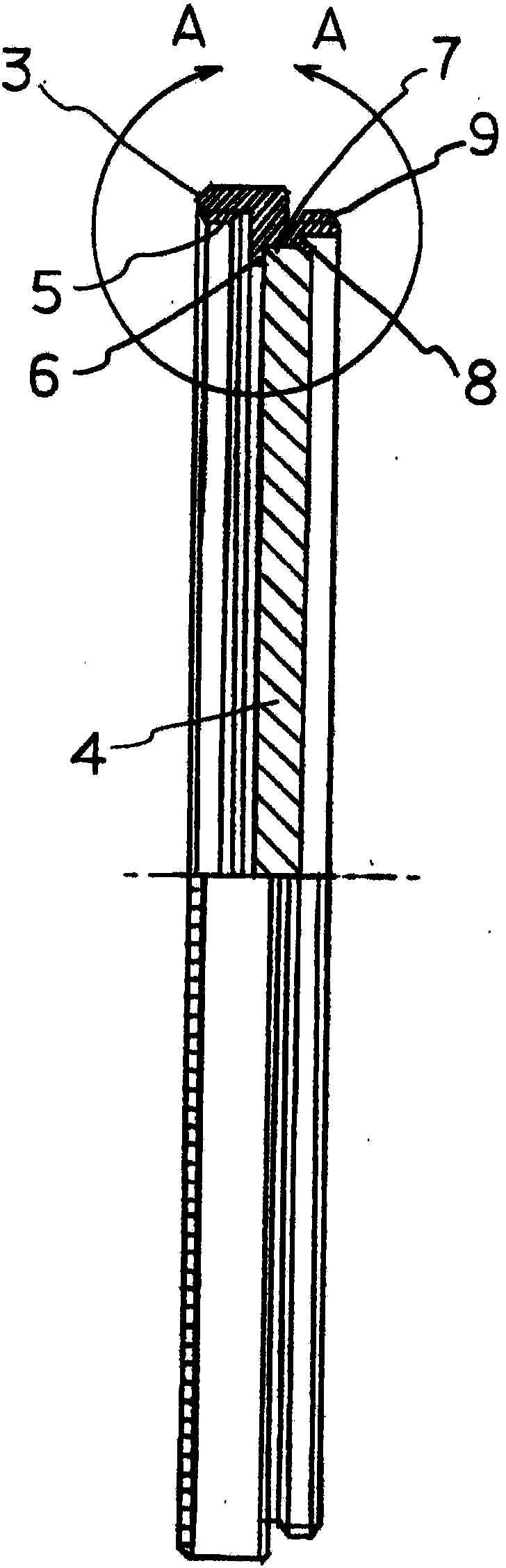

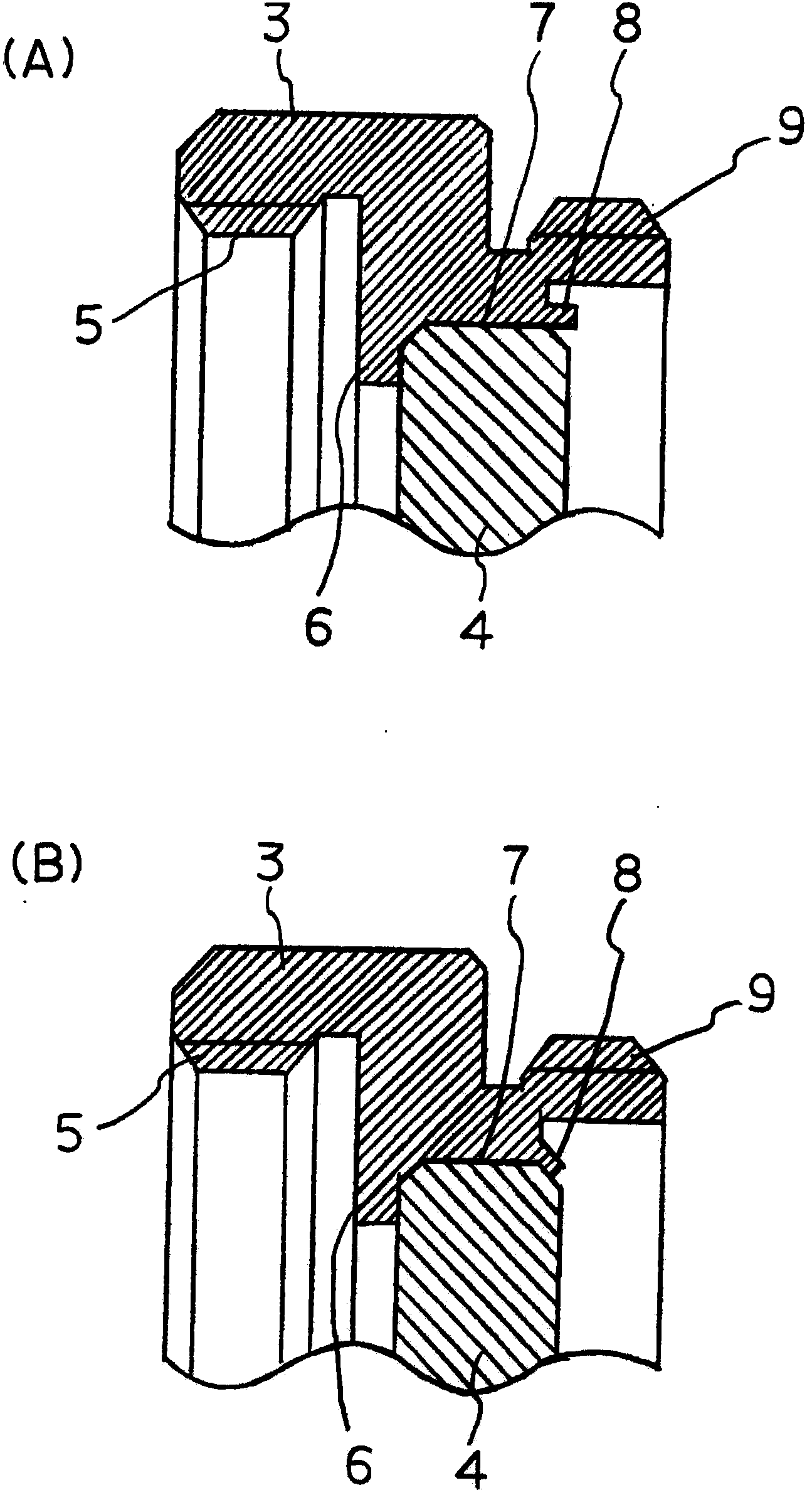

[0065] Figure 1 ~ Figure 3is a diagram illustrating the first embodiment of the present invention, figure 1 It is an explanatory diagram of the mounting position of the filter frame in the present invention, figure 2 is a sectional view of main parts for explaining the first embodiment, image 3 Parts (A), (B) of figure 2 The enlarged view of part A-A of , is an explanatory diagram of assembly operation.

[0066] exist figure 1 Among them, 1 is a main body of a digital single-lens reflex camera, 2 is a lens barrel part, and 3 is a filter frame main body for a digital camera made of a polymer elastic body. And above-mentioned filter lens frame main body 3 is installed in the front of lens barrel 2 of digital camera, plays the role of absorbing light, passing light or giving light change etc. through filter lens 4, namely, plays the role of controlling light according to the purpose, and The function of transmitting light into the imaging element of the camera, the digit...

no. 2 example

[0071] Figure 4 It is an assembly part diagram explaining the second embodiment. exist Figure 4 Among them, 10 is an internal thread member, 11 is a filter outer peripheral frame having a filter lens pressing inner section 12 inside, 13 is a filter lens, 14 is a filter lens pressing ring, and 15 is an external thread member. Moreover, for the above-mentioned internal thread member 10, filter outer peripheral frame 11, filter lens holding ring 14, and external thread member 15, thermosetting resins and / or thermoplastic resins and fiber-reinforced plastics using synthetic resins can be arbitrarily selected. Composite materials such as composite materials are used for forming processing, and the various parts processed by the forming process are assembled into a filter frame through heat riveting processing, ultrasonic welding, and adhesive and fixed connections using adhesive materials, thereby forming a high-quality Components of filter frames for digital cameras made of mo...

no. 3 example

[0076] figure 1 as well as Figure 5 , Figure 6 is a diagram illustrating a third embodiment of the present invention, figure 1 It is an explanatory diagram of the mounting position of the filter frame in the present invention, Figure 5 is a sectional view of main parts for explaining the third embodiment, Figure 6 Part (A) of Figure 5 The enlarged view of part B-B is the completed assembly view.

[0077] In this way, the third embodiment is the same as the first embodiment in figure 1 1 is the main body of the digital camera, 2 is the lens barrel, and 3 is the main body of the digital camera filter frame made of composite materials such as thermoplastic resin and fiber-reinforced plastic. Moreover, the above-mentioned filter lens frame main body 3 is mounted on the front of the lens barrel 2 of the digital camera, and plays the role of absorbing light, transmitting light, or giving light changes through the filter lens 4, that is, controlling the light according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com