A lotus root harvester

A harvester and lotus root technology, which is applied to harvesters, agricultural machinery and implements, etc., can solve the problems that the depth and range of water spray cannot be adjusted conveniently, the water spray device cannot move freely, and cannot meet the needs of harvesting, etc. , to achieve the effects of easy promotion and use, enhanced practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

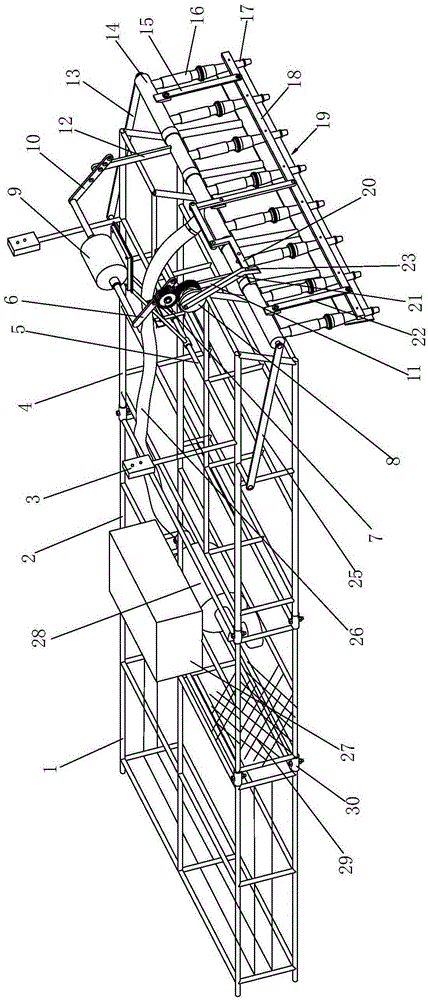

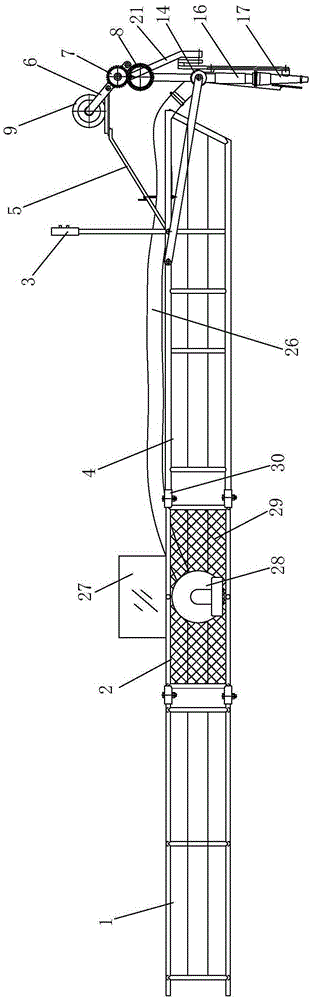

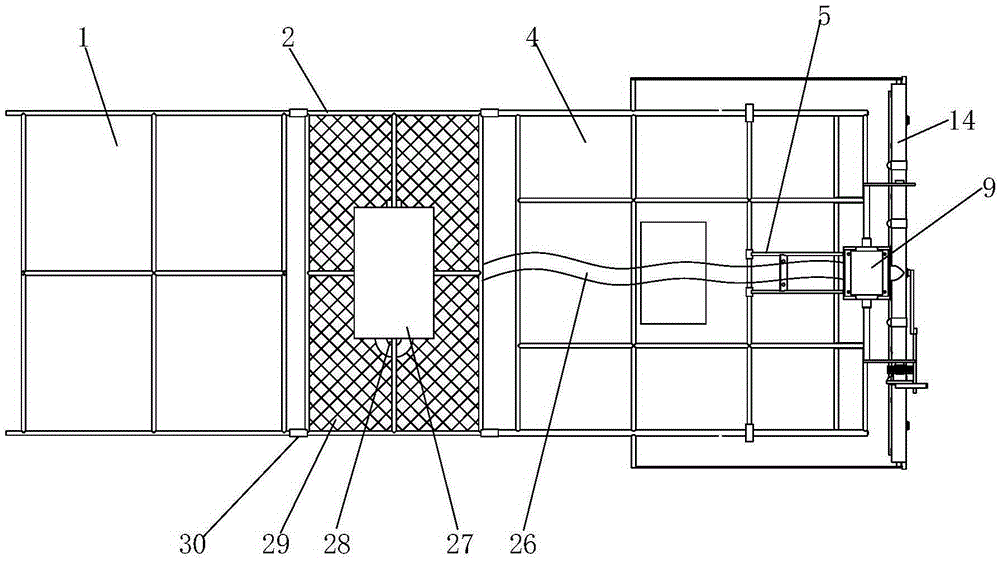

[0049] Such as figure 1 , figure 2 with image 3The shown lotus root harvester includes a combined buoyancy tank, on which a water spraying mechanism for spraying water to impact the soil above the lotus root is installed, and is used to pressurize and transport the water in the lotus root field to the The water delivery mechanism of the water spray mechanism, and the swing mechanism for driving the water spray mechanism to swing up and down. Picking lotus root organization19. The water spray mechanism is arranged at the front end of the first floating tank 4 .

[0050] Wherein, the combined pontoon is composed of the first pontoon 4, the second pontoon 2 and the third pontoon 1, and the second pontoon 2 is located between the first pontoon 4 and the third pontoon 1, Each floating tank can be connected by connecting piece 30, which is convenient for fastening and dismantling. After the combined floating tank is disassembled, it can be conveniently transported. In the slac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com