light miscellaneous separator

A separator and light impurity technology, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of poor impurity removal effect, grain materials cannot be spread evenly, and cannot guarantee the quality of materials Flow balance and other issues to achieve the effect of low air consumption and long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

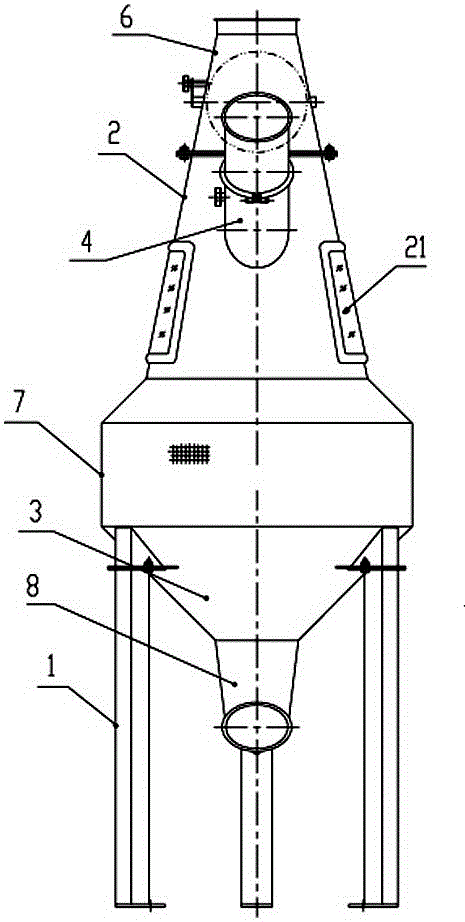

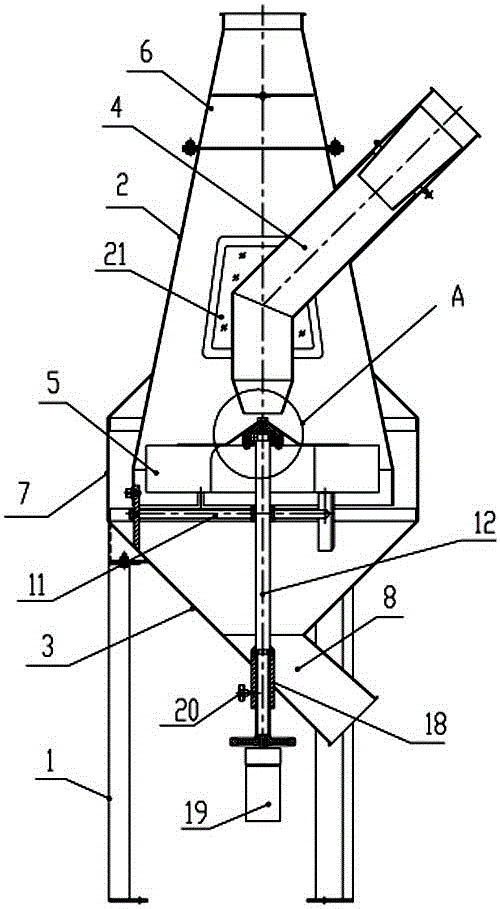

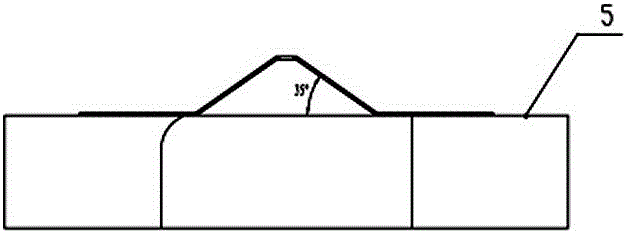

[0020] Such as figure 1 , 2 As shown, the light miscellaneous separator of the present invention includes a separation shell with a frame 1, and a feed inlet, a discharge port, an air inlet and a sundry collection port are opened on the separation shell, and the separation shell The body is composed of an upper chamber 2 and a lower chamber 3 connected by the inner cavity; the upper chamber 2 side wall of the positive conical cylinder structure is provided with a feeding port, and the feeding pipe 4 connected to the external feeding pipeline Extending from the feeding port into the upper chamber 2, a leveling pan 5 driven by a power source to rotate horizontally is provided near the bottom of the upper chamber, and the mouth of the feeding pipe 4 corresponds to the center of the leveling pan 5; An exhaust pipe 6 with an adjustable damper is connected to the mouth of the top of the upper chamber, and the exhaust pipe 6 is connected to the external centralized air network syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com