Automatic wheel hub cleaning device, automatic wheel hub cleaning system, and automatic wheel hub cleaning method

A technology for cleaning equipment and cleaning wheels, which is applied in chemical instruments and methods, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve problems such as unsatisfactory cooling effect, wheel hub cleaning equipment cannot adapt to automated production methods, etc. Fully automated operation, horizontal conveying movement and vertical lifting movement are compact, increasing the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

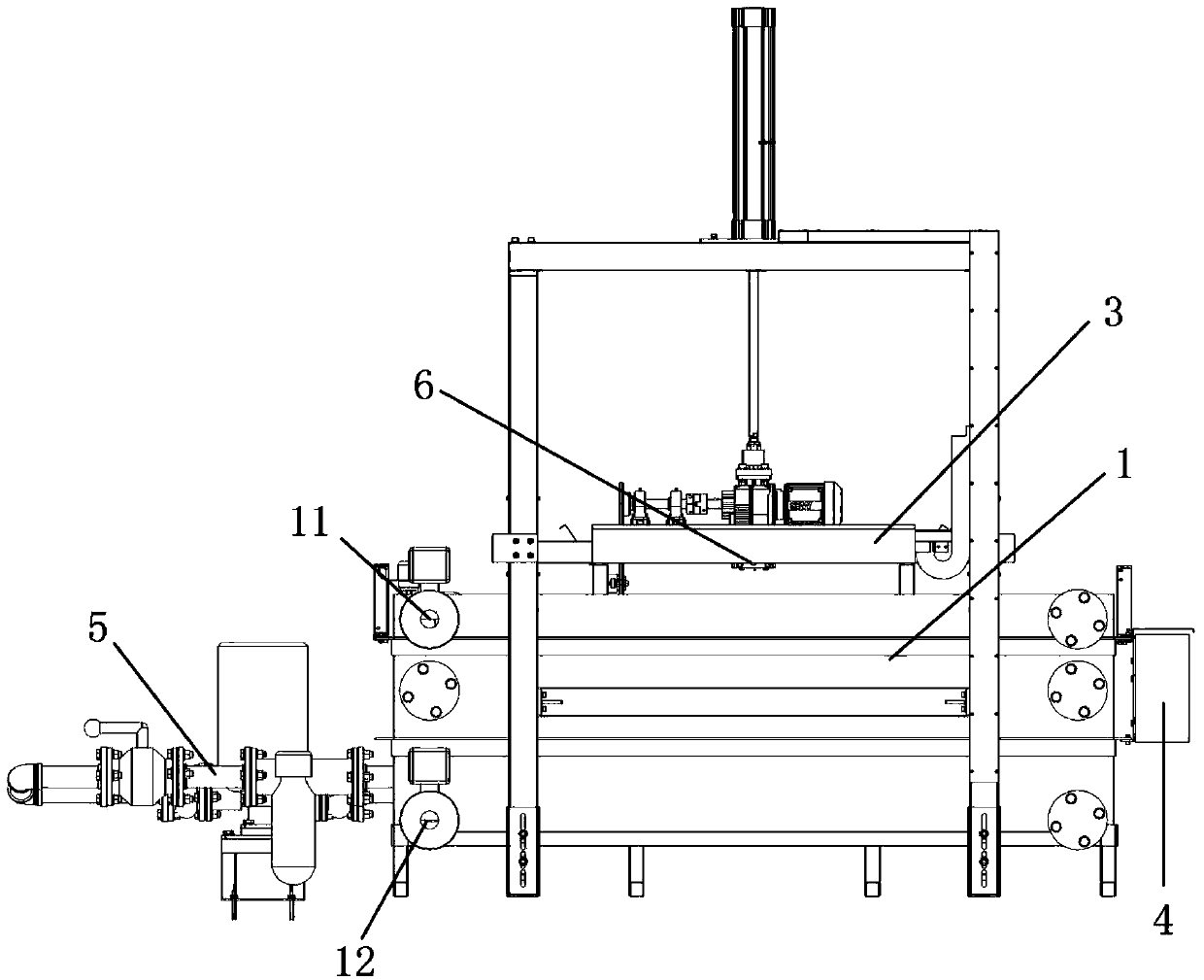

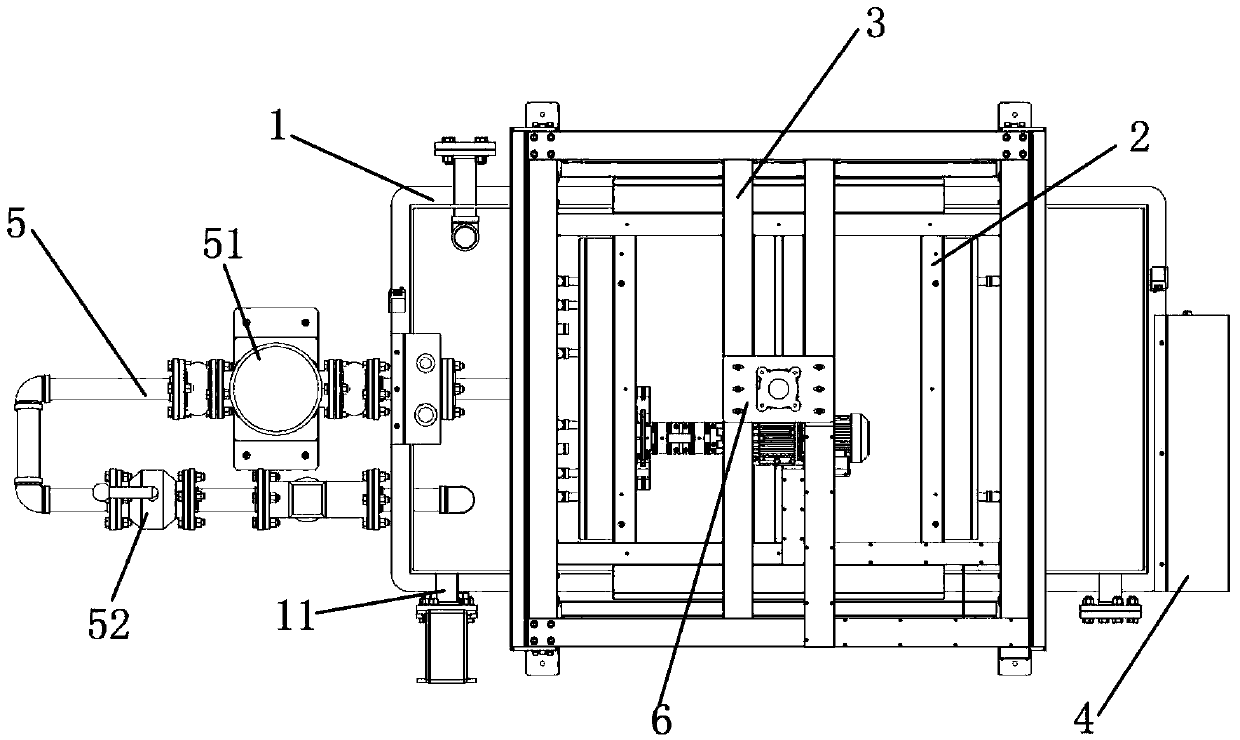

[0065] Such as figure 1 and 2 As shown, the present embodiment provides an automatic wheel hub cleaning equipment, comprising: a tank body 1 for storing cleaning liquid for cleaning the hub body, and a transportation device 2 arranged above the tank body 1 for supporting and transporting the wheel hub. The sensor 6 used to detect whether the hub is in place, and can automatically switch the transport device 2 to perform vertical lifting movement and horizontal transmission movement relative to the tank body 1 according to the signal of the sensor 6, so that the hub can complete entering and leaving the tank body 1 and a controller 4 that moves horizontally on said transport device 2.

[0066] The automatic hub cleaning equipment in this embodiment combines the positioning function of the sensor 6 with the control function of the controller 4, so that when the sensor 6 senses different signals, the controller 4 can separately control the transportation for supporting the hub. ...

Embodiment 2

[0082] This embodiment provides an automated hub cleaning and cooling system, including the automated hub cleaning equipment described in Embodiment 1, and also includes an input device adjacent to the entrance of the transport device 2 for inputting hubs to the transport device 2 , and the output device adjacent to the outlet of the transport device 2 for outputting the cleaned hubs on the transport device 2, the hubs are transported into the transport device 2 through the input device, after the hubs are cleaned, they are transported by the transport The device 2 is transported to the output device, which transports the hub to the next process.

[0083] In this embodiment, there are at least two hub cleaning equipments, and they are arranged side by side. The transmission device 2 of the previous hub cleaning equipment is connected with the transmission device 2 of the latter hub cleaning equipment to form a passage. So that the hub can be transmitted between the hub cleanin...

Embodiment 3

[0085] The present embodiment provides an automatic hub cleaning method, the method adopts the automated hub cleaning equipment described in Embodiment 1, comprising the following steps:

[0086] S1: Start the horizontal transmission movement of the transportation device 2, and the hub is transported by the transportation device 2 to the top of the tank body 1;

[0087] S2: After the sensor 6 senses that the hub is in place, it sends an in-position signal to the controller 4, and the controller 4 stops the horizontal transmission movement of the transportation device 2 after receiving the in-position signal, and starts to control the lifting device 3, The cylinder of the lifting device 3 performs contraction movement, driven by the contraction movement of the cylinder, the transportation device 2 makes a vertical downward movement relative to the tank body 1, so that the transportation device 2 drives the hub into the tank body 1 is cleaned by the cleaning solution;

[0088] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com