Ship tail bearing and tail pipe water lubrication device

A water-lubricated, tail-pipe technology, applied in the transmission device with synchronous propulsion components, etc., can solve problems such as oil-lubricated oil leakage and pollution, and achieve the effects of reducing maintenance costs, preventing insufficient water supply, and shortening maintenance periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

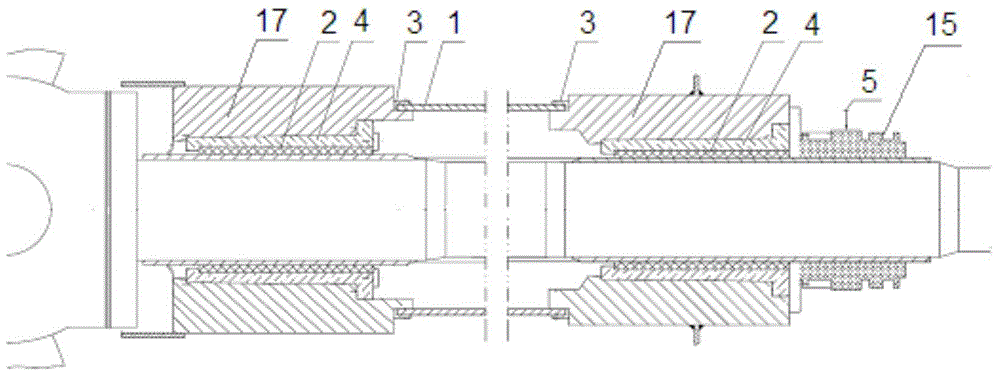

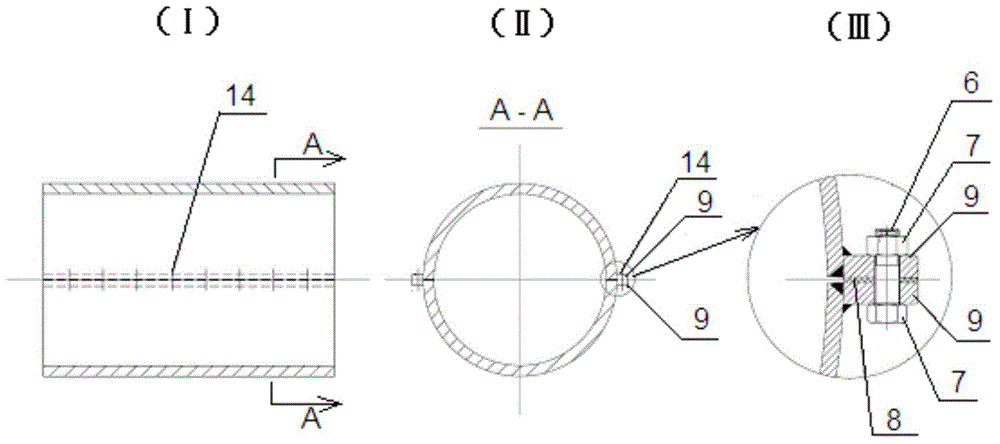

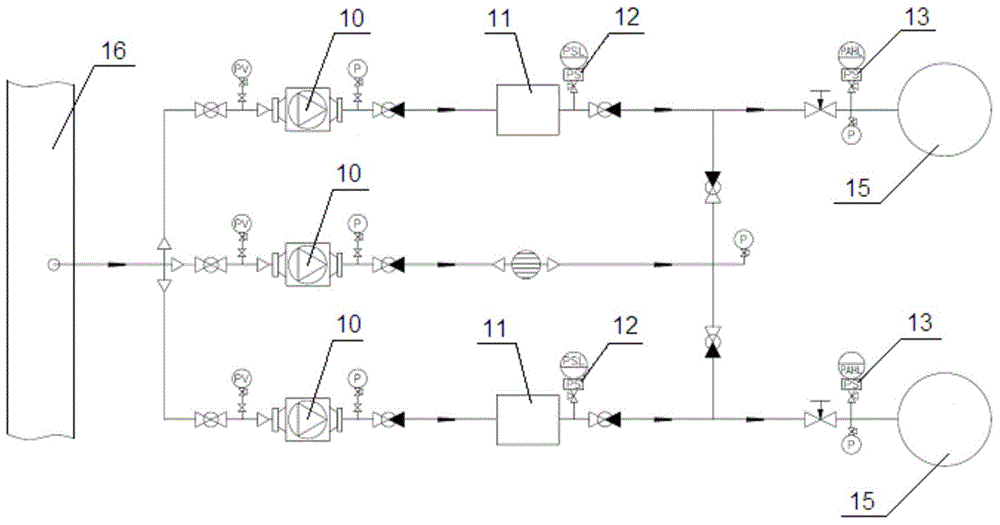

[0025] Such as figure 1 Shown is a water-lubricated stern shaft and stern tube device for a ship according to the present invention, including a stern bearing 2, a stern tube 1 and a support seat 17, and the stern bearing 2 and the stern tube 1 are fixed on the ship through the support seat 17 , the stern bearing 2 is a detachable two-half structure along its axial direction, and the stern tube 1 is divided into an upper half and a lower half of the stern tube 1 which can be separated along its axial direction, as figure 2 (I) and figure 2 (II) shown.

[0026] In one embodiment, such as figure 1 As shown, there is a junction between the tailpipe 1 and the support seat 17 , and the junction is a telescopic axial compensation structure 3 .

[0027] In the example, as figure 1 , figure 2 (I), figure 2 As shown in (II), there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com