Multi-line feeding system of freeze dryer and feeding method thereof

A feeding method and freeze-drying machine technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of blocked bottle transmission, inaccurate control, and increased positioning deviation, so as to reduce the risk of product contamination and equipment damage, The effect of increasing the accumulation area and avoiding bottle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

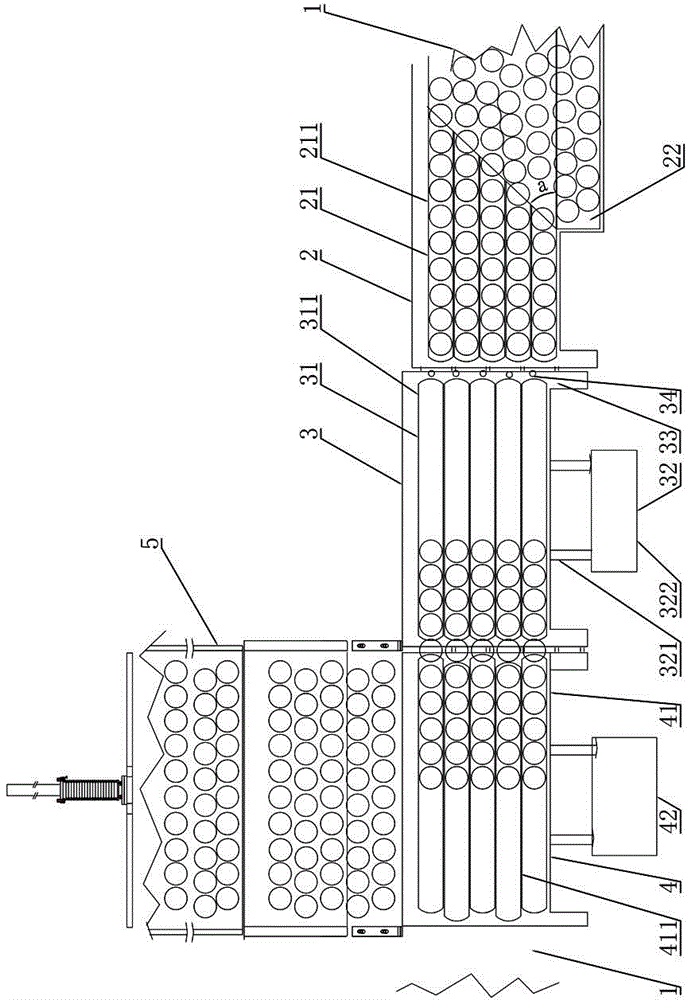

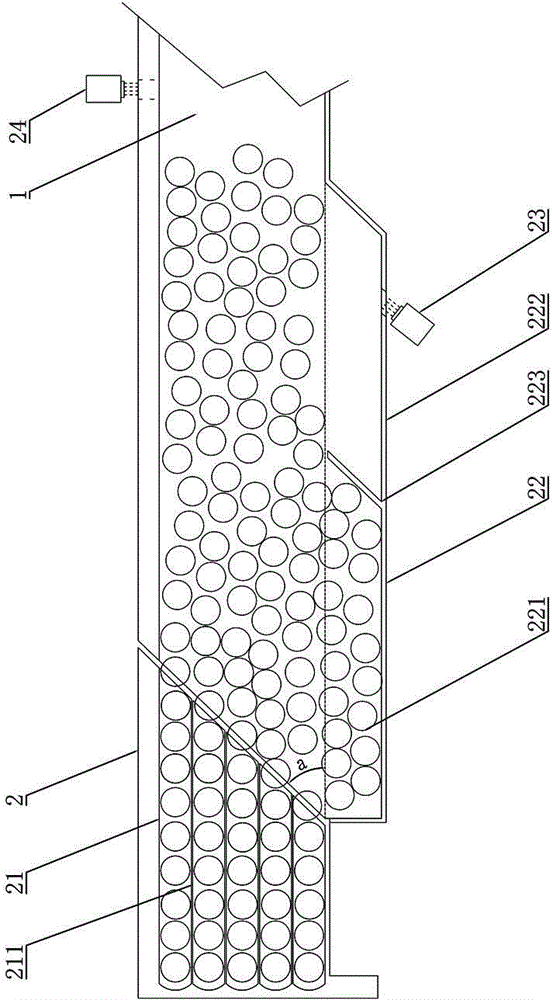

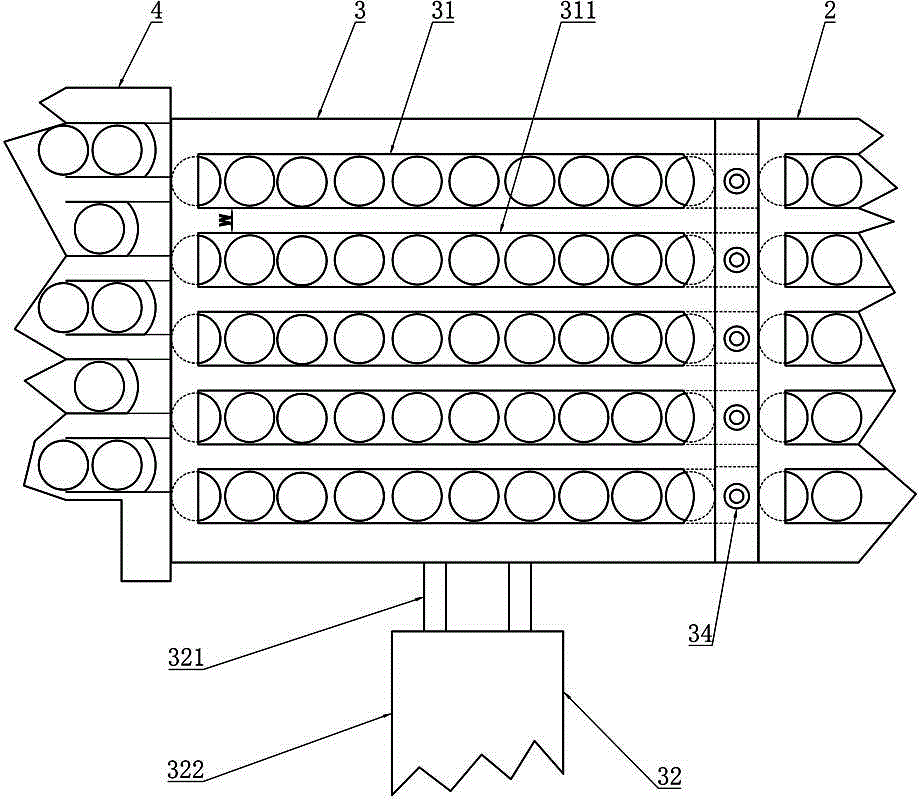

[0041] Such as Figure 1 to Figure 5 As shown, the multi-line feeding system of the freeze dryer in this embodiment includes a conveyor belt 1 and a freeze-drying box 5, and also includes a buffer pushing bottle pushing device 4 and an adapter device 3 for pre-pushing bottles into the freeze-drying box 5 And arrange the bottle unscrambler 2, arrange the bottle unscrambler 2, the transfer device 3 and the buffer push bottle device 4 in sequence along the bottle conveying direction of the conveyor belt 1, the buffer push bottle device 4, the transfer device 3 and the arrange bottle unscrambler 2 are equipped with at least three rows of bottle conveying passages, and the bottle conveying passages on the buffer push bottle device 4, the transfer device 3 and the bottle unscrambler device 2 are arranged in one-to-one correspondence, and the transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com