Preparation method for navy blue or black disperse dye

A disperse dye, navy blue technology, applied in the field of preparation of navy blue or black disperse dyes, can solve the problems of lack of washing fastness and sublimation fastness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] The former dye A1 shown in formula (I) gets 2 grams, A18 gets 8 grams, the former dye B1 shown in formula (II) gets 5 grams, B30 gets 7.5 grams, the former dye C6 shown in formula (III) gets 12.5 grams, the former dyestuff D3 shown in formula (IV) gets 15 grams, then adds 67 grams of dispersant MF, 8 grams of sodium lignin sulfonate, 153 grams of water and carries out dispersion treatment together with sand mill, then spray drying, to obtain final product Dye compositions of the invention.

Embodiment 2~27

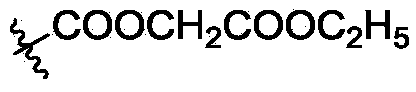

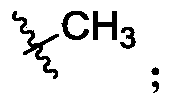

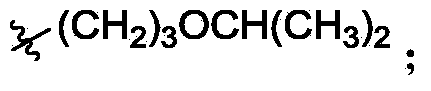

[0096] According to the preparation method of Example 1, according to the data shown in Table 5, at least one dye A, at least one dye B, at least one dye C, at least one dye D and dispersant MF, sodium lignosulfonate Blending with water, sand milling to disperse, and spray drying to obtain finished disperse dyes. Among them, the structural formulas defined by the substituents of the dyes A, B, C, and D are shown in Tables 1 to 4.

[0097]

[0098]

[0099]

[0100]

[0101]

[0102]

[0103]

[0104]

[0105]

[0106]

Embodiment 28

[0108] Take 2.5 grams of the disperse dyes prepared in Examples 1-27 and disperse them in 500 milliliters of water to form a dye suspension, draw 20 milliliters and mix them with 80 milliliters of water, adjust the pH of the dyeing bath to 4-5 with acetic acid, and heat up to 70 °C At the same time, put 5 grams of polyester fiber cloth for dyeing, heat up from 70°C to 130°C within 30 minutes, keep warm for 50 minutes, cool to below 90°C, drain and wash. Then put the cloth sample into 100 milliliters of reducing cleaning solution containing 1 gram per liter of caustic soda and 3 gram per liter of hydrosulfite to clean at 80° C. for 20 minutes. According to the national standard GB / T2397-2003, the lifting power of the disperse dyes prepared in Examples 1 to 27 was measured, and the national standard GB / T3921-2008, GB / T3920-2008, GB / T8427-2008, GB / T5718-1997 were used to test their resistance Washing, rubbing, light fastness and sublimation color fastness. The test results are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com