LNG automobile air conditioner exchanger controllable in water quantity and water temperature

A technology of automotive air conditioners and exchangers, applied in the field of exchangers, can solve the problems of high manufacturing cost and high cost, and achieve the effects of volume and easy installation, cost saving, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

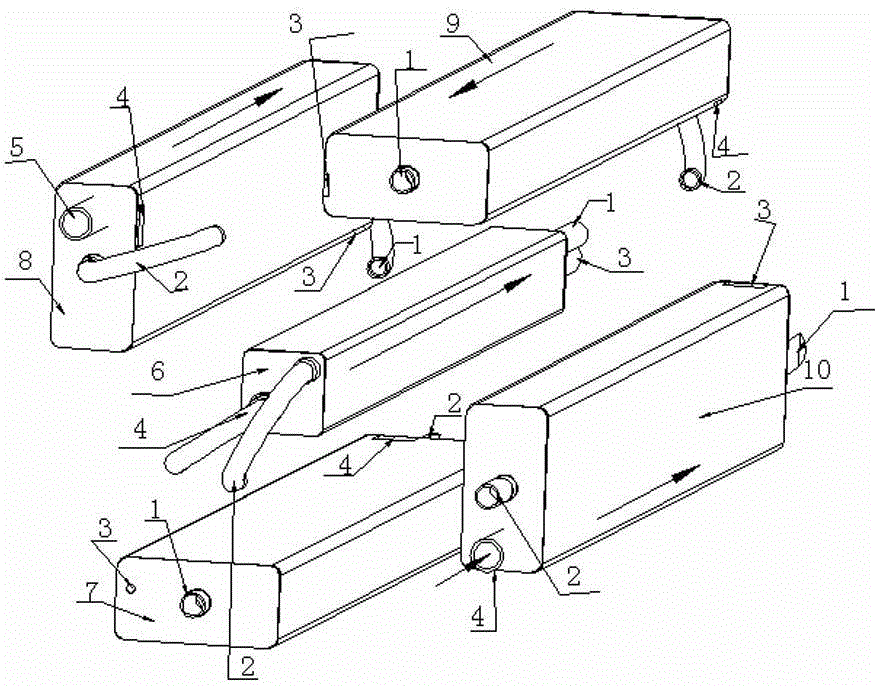

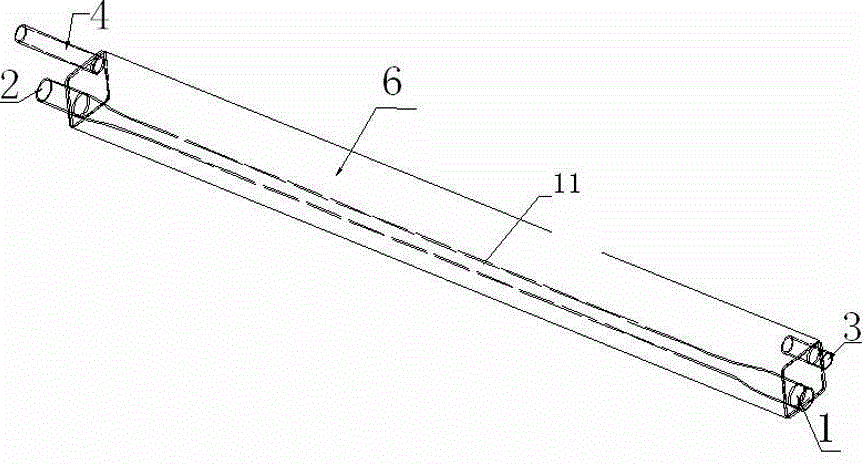

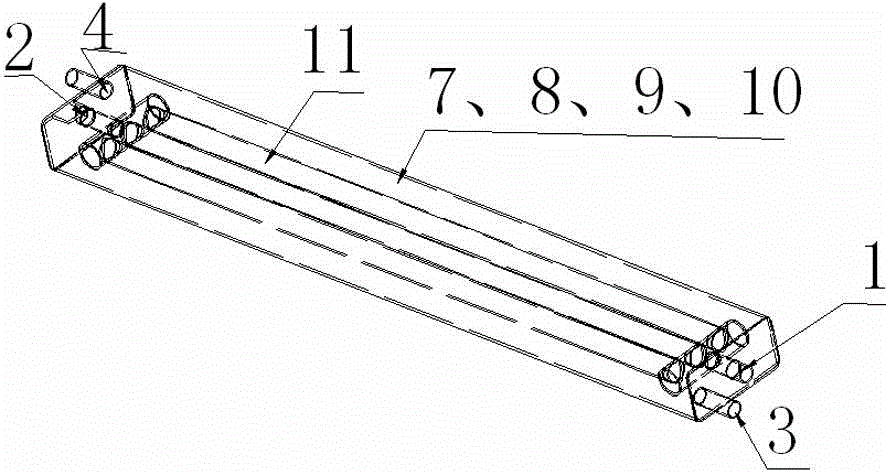

[0029] The present invention as figure 1 , 2 , 3, 4 shown.

[0030] An LNG automotive air-conditioning exchanger with controllable water volume and water temperature, comprising a plurality of cavities sealed at both ends, and the multiple cavities are arranged side by side to form a whole, wherein the cavity-6 is surrounded by multiple cavities, and each cavity The body is provided with a pipeline 11, and the two ends of the pipeline 11 run through and extend out of the cavity to form a tube one 2 and a tube two 1, and the two ends of the cavity are respectively provided with a port one 3 and a port two 4, and the tube two 1 and the tube two 1 of the cavity one 6 Port 1 and 3 are the water outlet and air inlet respectively; the connection mode of cavity 1 6 and cavity 2 7 is that the tube 1 2 of cavity 1 6 is connected in series with the port 1 3 of cavity 2 7, and the connection mode of cavity 1 6 is Port 2 4 and tube 1 of cavity 2 7 are connected in series; tube 2 1 of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com