Energy-saving environmentally friendly material drying device

A drying device, energy-saving and environment-friendly technology, which is applied in the direction of heating device, drying solid materials, drying, etc., can solve the problems of affecting normal discharge, troublesome cleaning, dust deposition in the inner cavity of the dryer, etc., so as to improve heat utilization rate and improve Heat exchange area, effect of large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

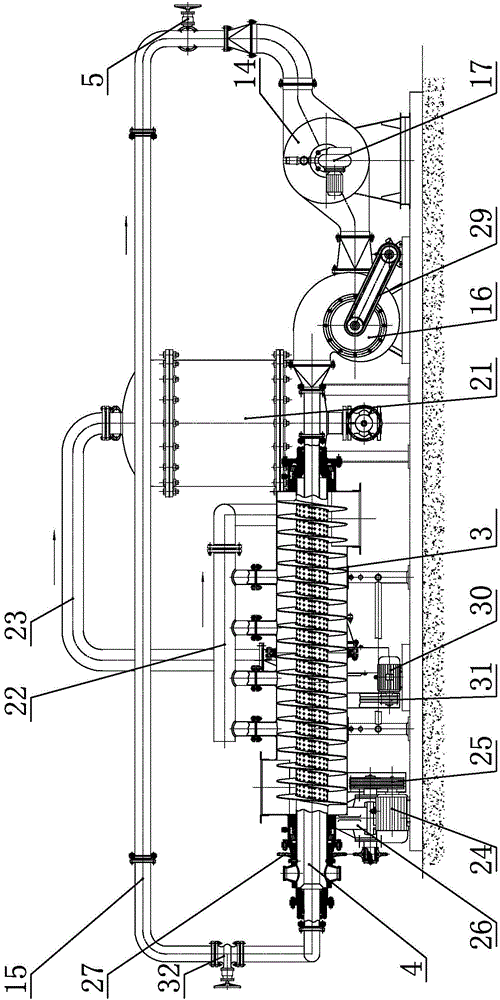

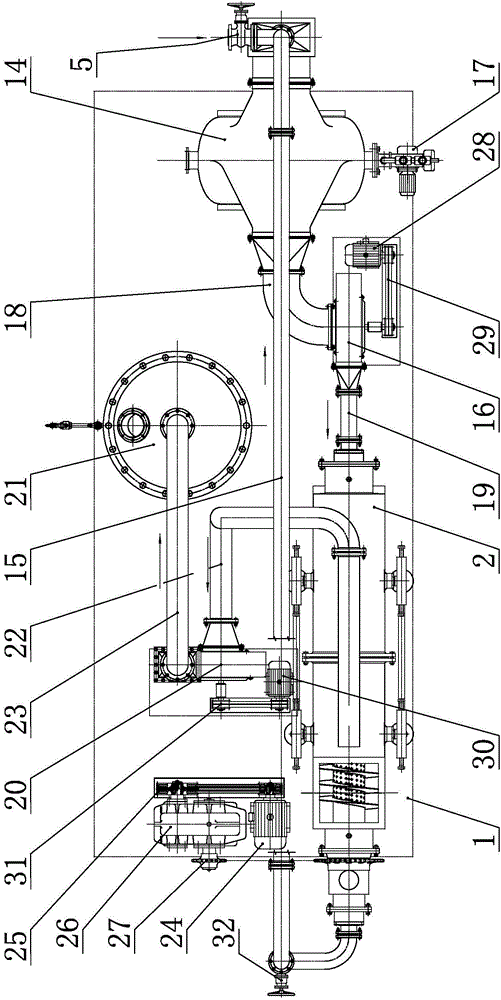

[0030] combine figure 1 —— image 3 As shown, an energy-saving and environment-friendly material drying device is mainly composed of a material dryer, a hot air transmission part and a dusty water vapor treatment part.

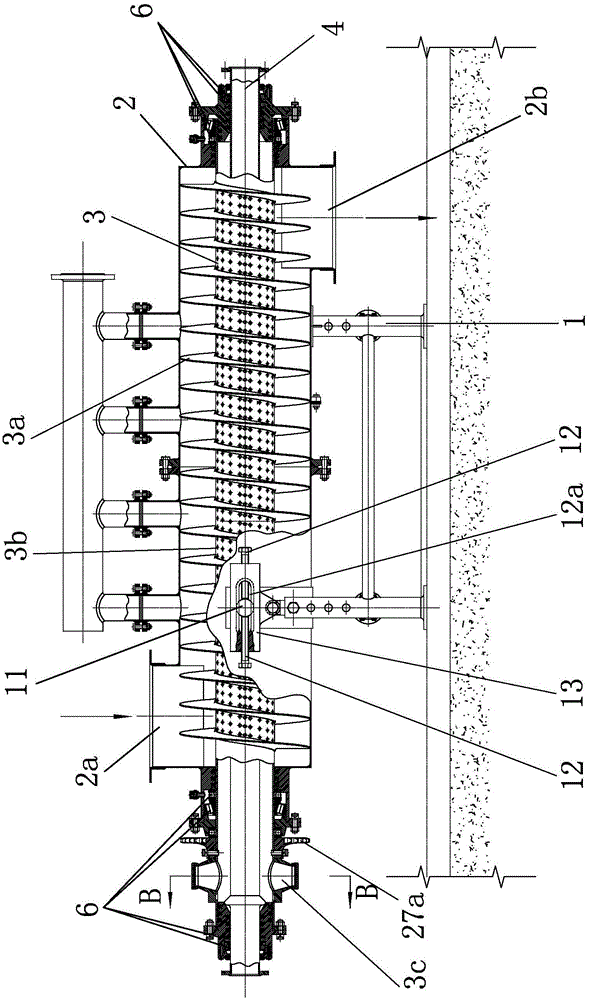

[0031] combine image 3 , Figure 4 As shown, the material dryer is mainly composed of a dryer shell 2, a drying pipe 3, an air distribution pipe 4, a first bearing 6 and a first power mechanism. The shell 2 of the drier is arranged horizontally and is preferably cylindrical. The dryer shell 2 is installed on the base frame 1, and the base frame 1 is used for supporting and fixing the dryer shell 2.

[0032] The dryer shell 2 is provided with a feed port 2a and a discharge port 2b, and the material enters from the feed port 2a and is discharged from the discharge port 2b (such as image 3 indicated by the middle arrow). The drying pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com