Safety firecracker gunpowder mixing and filling equipment

A safe, powder-charging technology, applied in the direction of offensive equipment, weapon types, pyrotechnics, etc., can solve the problems that the degree of automation affects the safety of the production process, the efficiency of charge affects the manufacturing cost of firecrackers, and the quality of charge affects the quality of firecrackers. Generate static electricity and electrical sparks, prevent personal safety accidents, and reduce operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

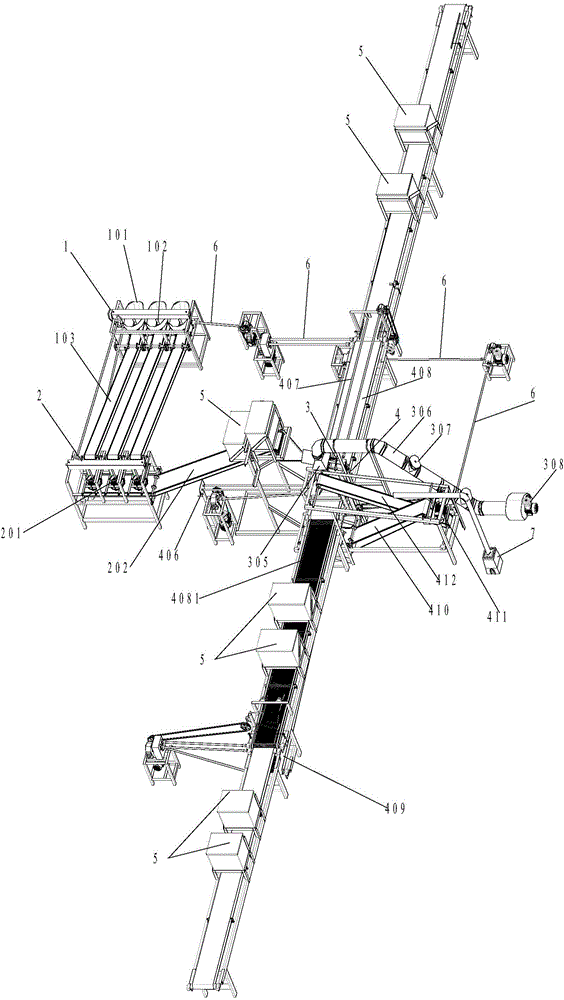

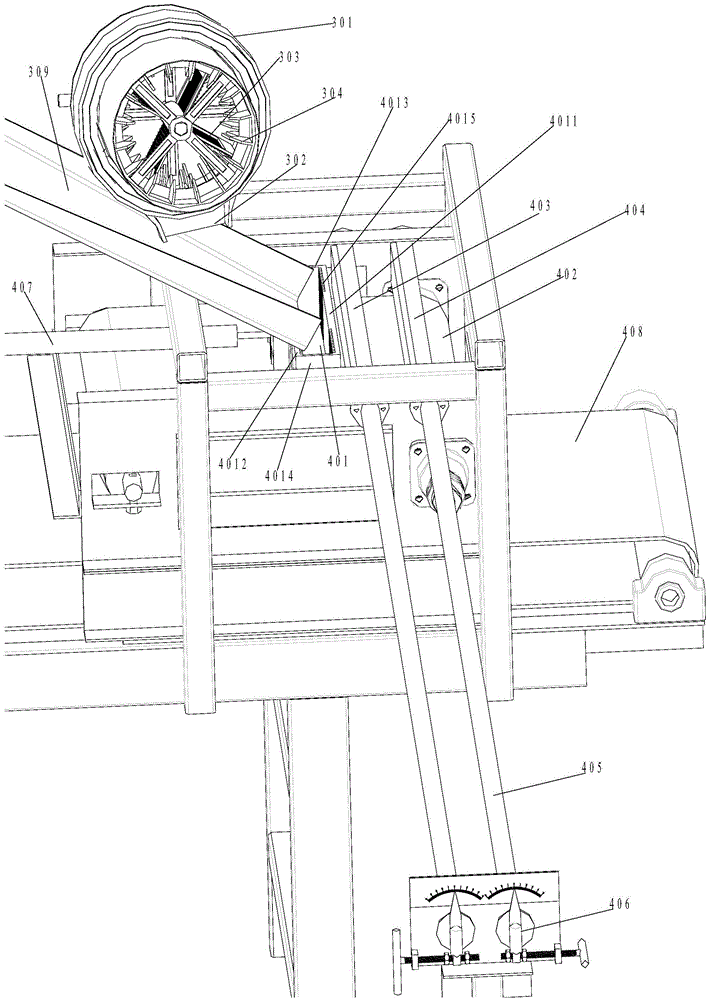

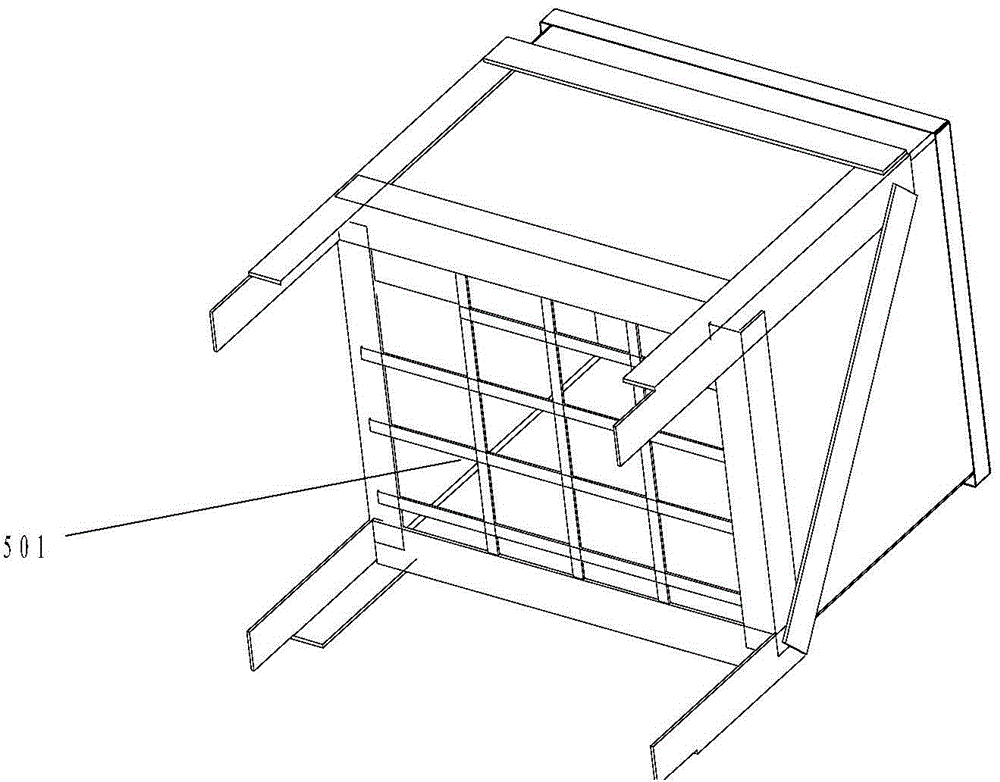

[0023] Embodiment 1: Referring to the accompanying drawings, reflecting a specific structure of the present invention, the safety type firecrackers and medicine charge equipment include a feeding mechanism 1, a screening mechanism 2, a mixing mechanism 3 and a filling mechanism connected in sequence by a conveyor belt 4. The mixing mechanism 3 and the filling mechanism 4 are separated by an explosion-proof wall into an independent charging room. A conveyor belt passage port is provided on the explosion-proof wall, and a fire-fighting water tank 5 is provided at the conveyor belt passage port. Shaped bottom 501, the fire-fighting water that device fills in the film bag in fire-fighting water tank 5; There is at least one aluminum roller on each conveyor belt; the ground is covered with anti-static mats, and the equipment is equipped with a grounding device.

[0024] The feeding structure includes three feeding hoppers 101. The feeding hoppers 101 are made of all-copper material...

Embodiment 2

[0032] Embodiment 2: The difference from Embodiment 1 is only that the shape of the stirring blades is different, and a number of "8"-shaped stirring blades 802 are fixed on the inner wall of the mixing tube 801. The "8"-shaped stirring blades 802 The middle part is the smallest, and gradually enlarges from the middle part to both ends. One enlarged end is fixed on the inner cavity wall of the mixing cartridge 801, and the other end has an arc-shaped end. Repeated practice has proved that the "8"-shaped stirring blade 802 and the copper screen 803 prevent the generation of static electricity, and at the same time have a high mixing efficiency on the basis of ensuring safety. It can process about 2,000 firecracker tube cakes per hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com