Spot check agent, spot check device and manufacturing method of spot check agent

A spot inspection and container technology, applied in the field of spot inspector and spot inspection agent production, spot inspection agent, can solve the problems of inability to check whether the alarm can be alarmed, complicated operation, etc., and achieve the effects of fast inspection, sensitive response, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

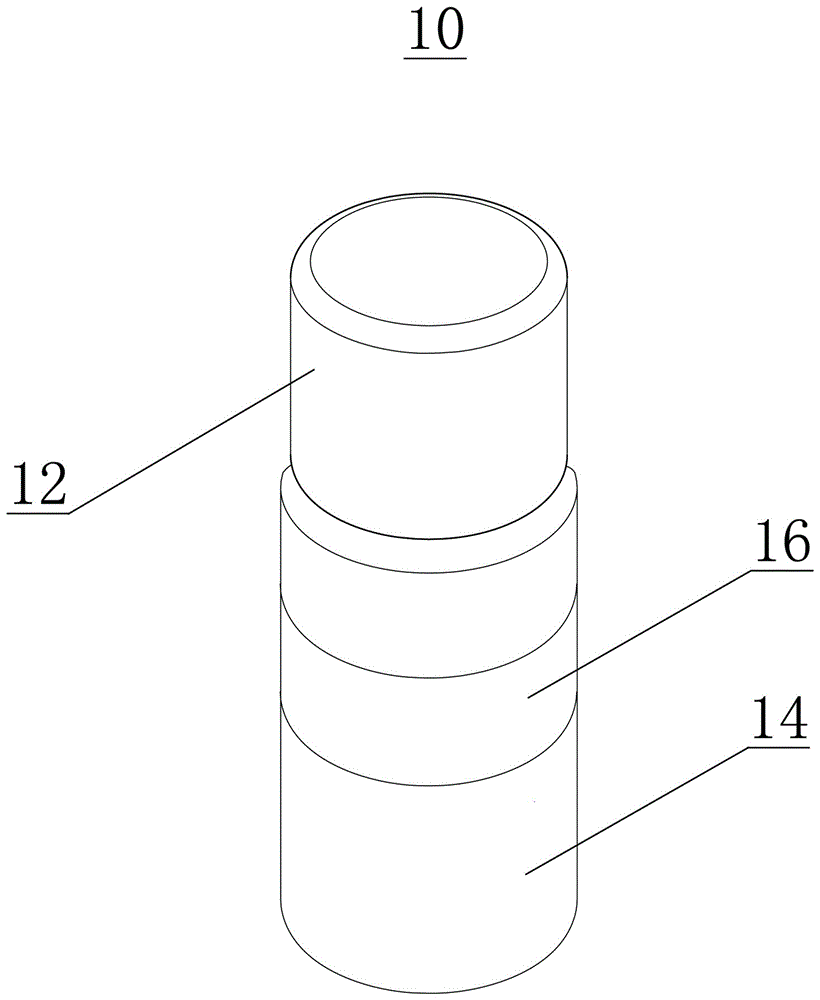

[0041] see figure 1 , the present embodiment 1 provides a spot checker 10, the spot checker 10 includes a jar 12 and a spot check agent 14 and a sponge 16 sealed in the jar 12, wherein the sponge 16 is stacked on the spot check agent 14 for the upper gate. The sealing cap of the wide-mouth bottle 12 is fixed on the mouth of the wide-mouth bottle 12 by means of a screw.

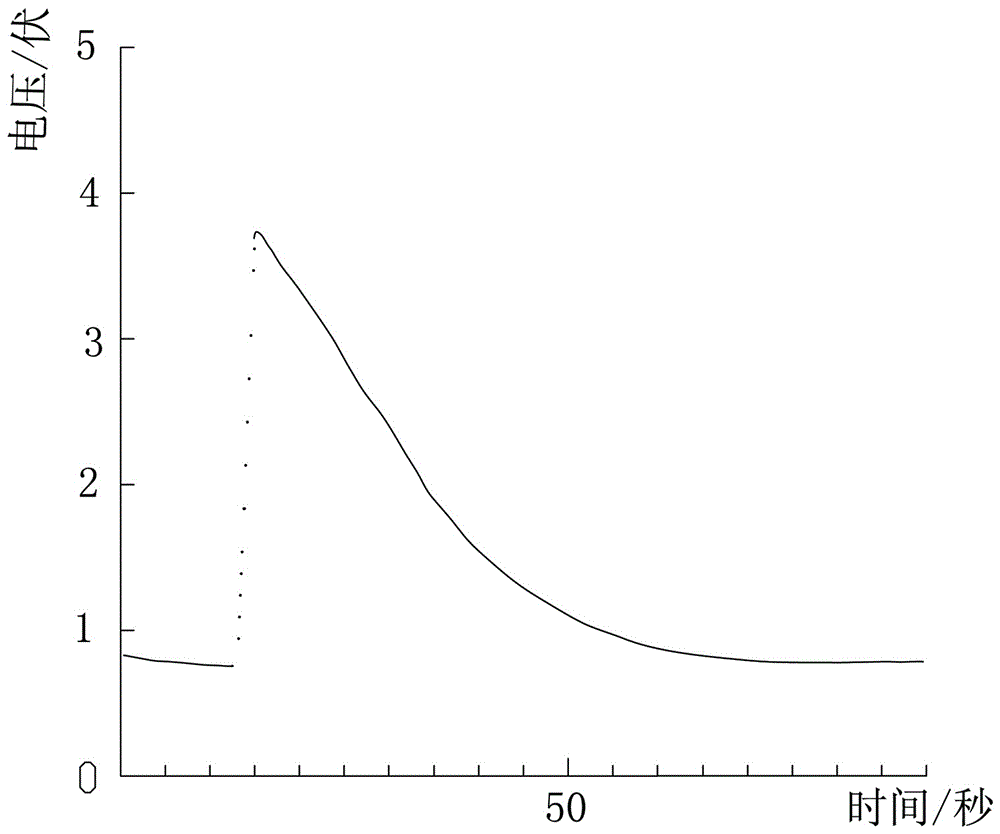

[0042] The preparation method of described inspection agent 14 is: take by weighing 3 grams of stearic acid, 1 gram of paraffin, several grains of zeolite, pour into three-necked beakers, inject 20 milliliters of cyclohexane, 10 milliliters of normal hexane, and 3 milliliters of water into it, Use a water bath to heat, the temperature is controlled at about 65°C, keep warm until completely dissolved; measure 2 ml of water into the beaker, add 1 g of NaOH, shake well until completely dissolved, then measure 10 ml of cyclohexane into the beaker, mix well Then slowly pour it into a three-neck flask. Heating fo...

Embodiment 2

[0046] Weigh 3 grams of stearic acid and several zeolites, and pour them into three-necked beakers. Measure 30 milliliters of ethanol, 10 milliliters of n-hexane, 10 milliliters of n-octane, and inject 3 milliliters of water into it, heat it in a water bath, control the temperature at about 65°C, and keep it warm until completely dissolved; measure 2 milliliters of water into the beaker, add 1 gram of NaOH, shake until completely dissolved, then measure 10 ml of ethanol and pour it into a beaker, mix well and slowly pour it into a three-neck flask. Heated for 4 minutes, stopped heating and poured into a wide-mouthed bottle to obtain a spot check agent, and simultaneously obtained a spot check device. The components of the inspection agent are: 5.8% sodium stearate, 58.0% ethanol, 14.5% n-hexane, 14.5% n-octane and 7.2% water.

[0047] The structure of the spot checker using the above-mentioned spot check agent is the same as that of the spot checker 10 provided in Embodiment ...

Embodiment 3

[0050] Weigh 3 grams of stearic acid and several zeolites, and pour them into three-necked beakers. Measure 20 milliliters of ethanol, 20 milliliters of n-hexane, and 5 milliliters of water into it, heat it in a water bath, control the temperature at about 65°C, and keep it warm until completely dissolved; measure 3 milliliters of water into a beaker, add 1 gram of NaOH, and shake well until All dissolved, then measure 10 ml of ethanol and pour it into a beaker, mix well and slowly pour it into a three-neck flask. Heated for 6 minutes, stopped heating and poured into the mold to obtain the spot check agent. The components of the inspection agent are: 6.5% sodium stearate, 49.1% ethanol, 32.8% n-hexane and 11.5% water.

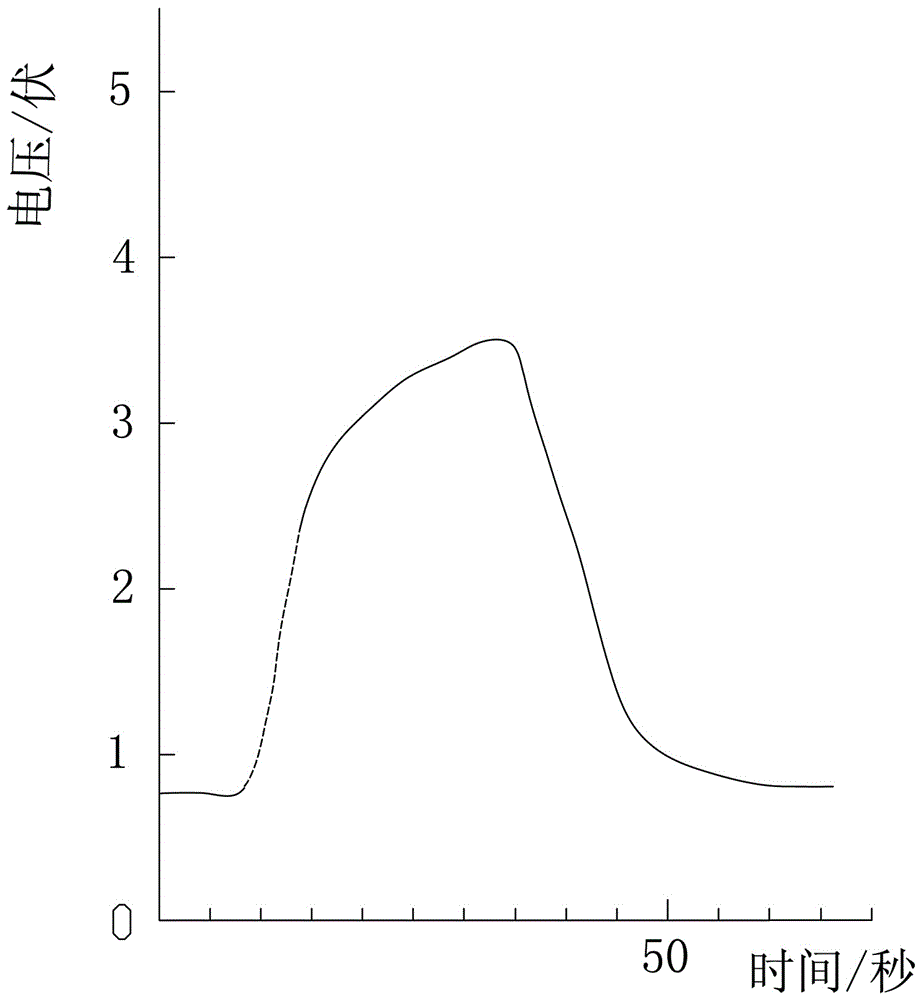

[0051] The structure of the spot checker using the above-mentioned spot check agent is the same as that of the spot checker 10 provided in Embodiment 1. Place the spot checker near the air inlet of the online GDII household combustible gas alarm, check the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com