Liquid crystal display device

A liquid crystal display device and liquid crystal display technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high production cost, increased front shell processing design, and inability to realize borderless design, so as to realize design and reduce production Cost, to achieve the effect of borderless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

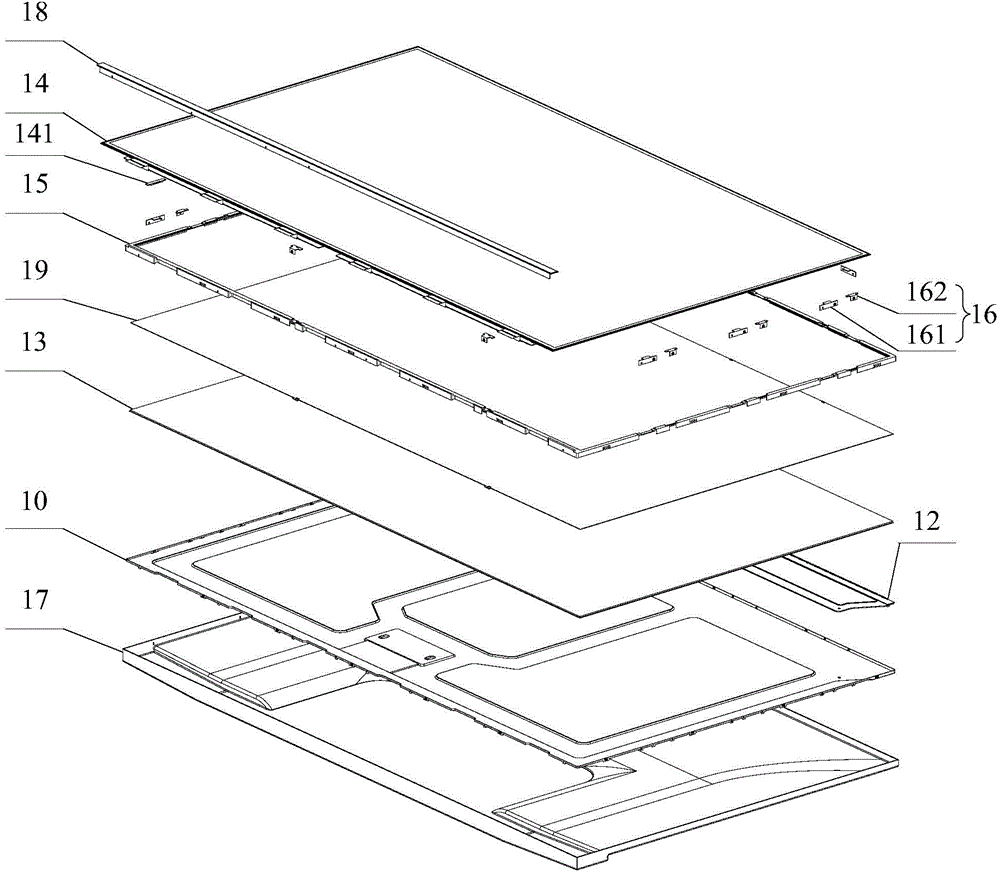

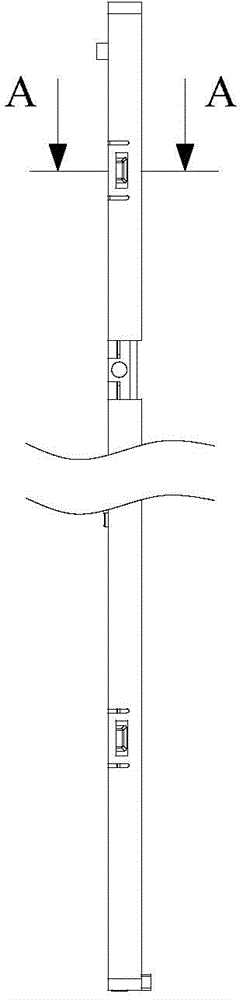

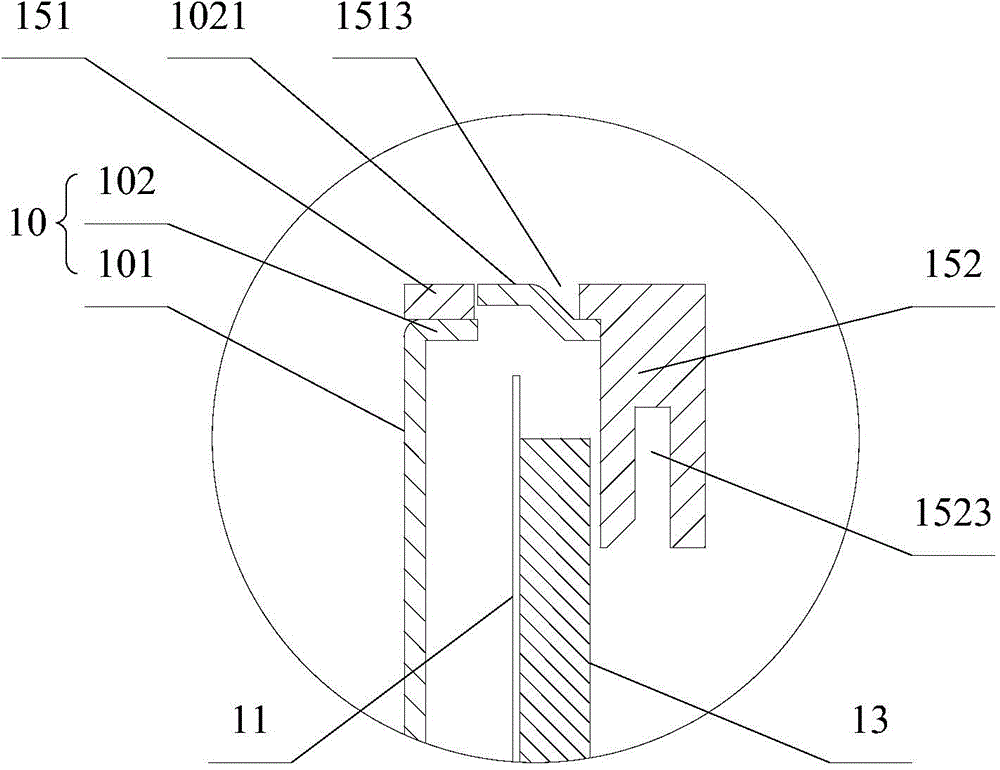

[0032] The invention provides a liquid crystal display device, referring to Figure 1 to Figure 3 , in one embodiment, the liquid crystal display device includes a backplane 10, a reflector 11, a light bar 12, a light guide plate 13, a liquid crystal display 14, a middle frame 15 and a connector 16, and the backplane 10 includes a bottom plate 101 And the side walls 102 extending upward from the four sides of the bottom plate 101, the side walls 102 and the bottom plate 101 are surrounded to form a housing cavity; the reflector 11, the light bar 12 and the light guide plate 13 are all located in the housing cavity, and the reflector 11 is located between the light guide plate 13 and the bottom plate 101, the light bar 12 is fixedly connected to the bottom plate 101, and the light bar 12 is located on one side of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com