Image ROI positioning method and device based on dimension invariant feature transformation during automobile instrument panel visual detection

A scale-invariant feature, automotive dashboard technology, applied in image analysis, image data processing, instruments, etc., can solve the problem of the influence of image features to be detected, poor ROI positioning effect, etc., to avoid the influence of ROI positioning results Good stickiness and ROI positioning effect, avoiding different effects of feature point sets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

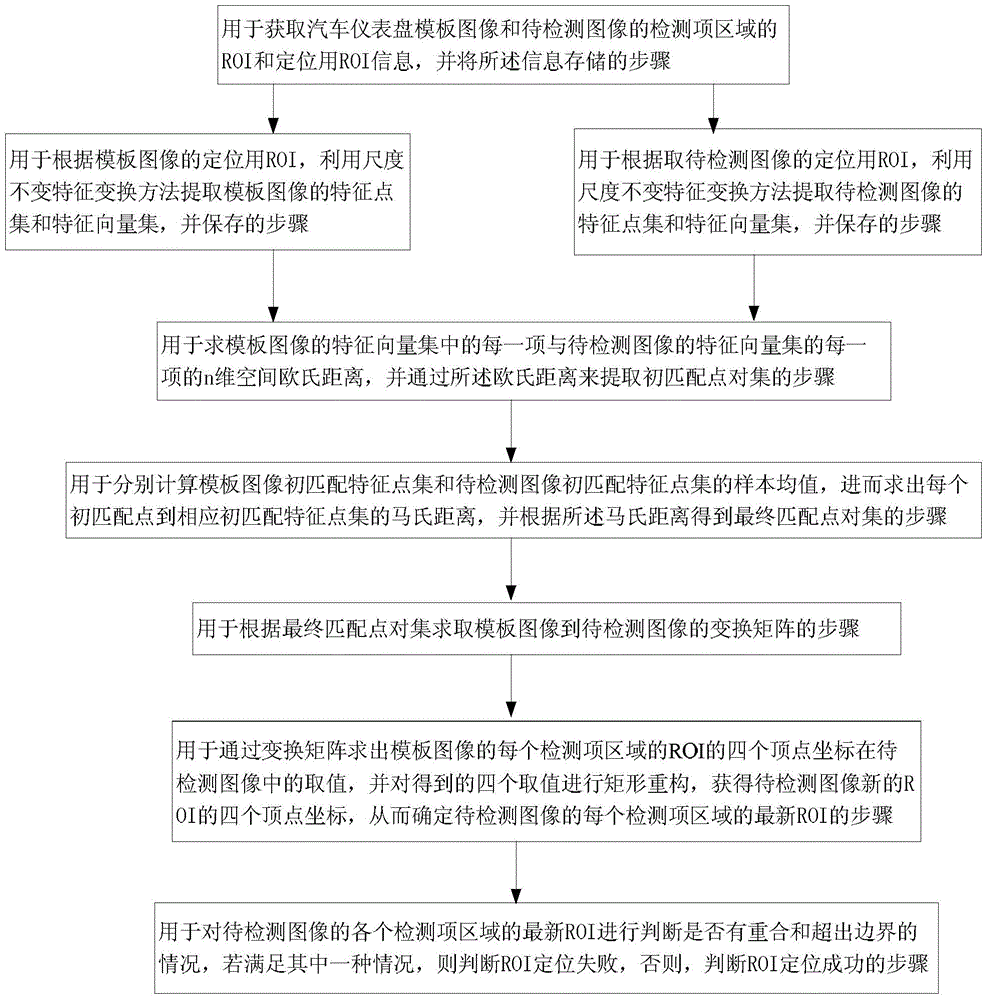

[0036] Specific implementation mode one: combine figure 1 Describe this embodiment, the image ROI positioning method based on scale-invariant feature transformation in the automobile dashboard visual detection described in this embodiment, it comprises the following steps:

[0037] A step for obtaining the ROI and positioning ROI information of the vehicle dashboard template image and the detection item area of the image to be detected, and storing the information;

[0038] A step for extracting a set of feature points and a set of feature vectors of the template image using a scale-invariant feature transformation method according to the ROI for positioning of the template image, and saving them;

[0039]A step for extracting a set of feature points and a set of feature vectors of the image to be detected by using a scale-invariant feature transformation method according to the ROI for positioning of the image to be detected, and saving;

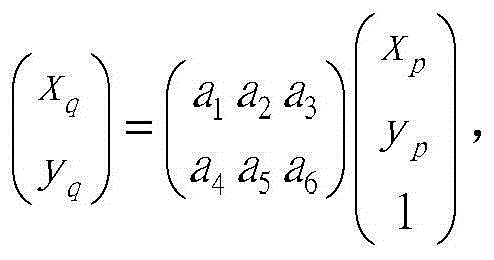

[0040] For finding the n-dimensio...

specific Embodiment approach 2

[0057] Specific embodiment 2: This embodiment is a further limitation of the image ROI positioning method based on scale invariant feature transformation in the visual detection of automobile instrument panel described in specific embodiment 1. Item and the n-dimensional space Euclidean distance of each item of the feature vector set of the image to be detected, and the steps of extracting the initial matching point pair set by the Euclidean distance include:

[0058] It is used to select a feature vector from the feature vector set of the template image, and take the Euclidean distance from all feature vectors in the feature vector set of the image to be detected, where the minimum distance is Edis 1 , the next smallest distance is Edis 2 , when Edis 1 ≤β*Edis 2 , then the corresponding two feature points are the steps of the initial matching point pair

[0059] The β is the Euclidean distance multiple threshold value, and the value range of β is 0.5-0.9;

[0060] It is u...

specific Embodiment approach 3

[0066] Embodiment 3: This embodiment is a further limitation of the image ROI positioning method based on scale-invariant feature transformation in the visual detection of automobile dashboard described in Embodiment 2, β=0.75.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com