Incandescent lamp

An incandescent lamp and lamp cap technology, applied in the field of incandescent lamps, can solve the problems of inability to guarantee the effect, deviation of the filament from the correct position, short service life of the incandescent lamp, etc., and achieve the effect of avoiding premature wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

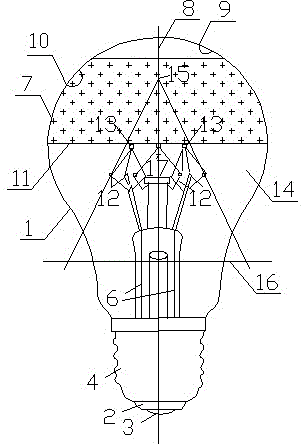

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

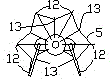

[0016] figure 1 The incandescent lamp has a vacuum-sealed glass bulb 1. The bulb 1 is equipped with a lamp cap 2 with contacts 3 and 4. The bulb 1 is equipped with a filament 5, which is connected to the contacts 3 and 4 of the lamp cap 2 through a current supply conductor 6. 2 Opposite the bulb there is a hemispherical part 7 which has an axis of symmetry 8 and a mirror coating 10 , with the exception of parts close to and around the axis 8 which do not have a mirror coating. In the illustrated incandescent lamp the bulb 1 is transparent with the exception of the mirror coating 10. In the embodiment shown the mirror coating 10 is an internal coating deposited by aluminum vapor, and it is advantageous that the bulb be transparent because it allows the light to The filament 5 is arranged on several support points 12, 13 around the axis of symmetry 8 near the widest in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com