A heat-shrinkable plastic film shell disposable lithium ion battery and its manufacturing method

A technology for lithium ion batteries and plastic films, which is applied in the manufacture of primary batteries, electrolyte batteries, secondary batteries, etc., can solve the problems of increased manufacturing material costs, expensive electronic cigarettes, and reduced smoking, and achieve increased capacity and increased capacity. , low cost, the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, invention is described in further detail.

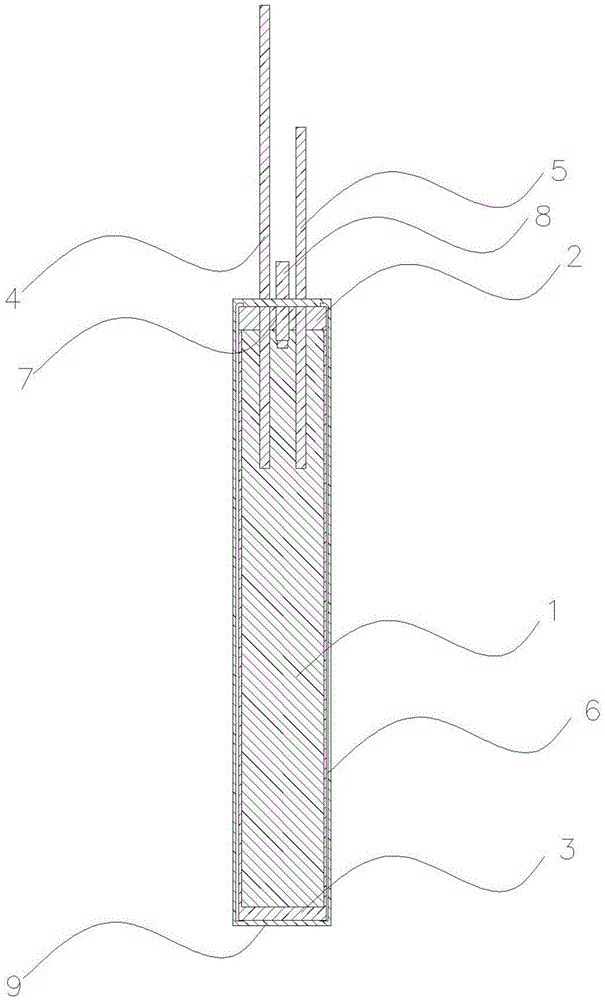

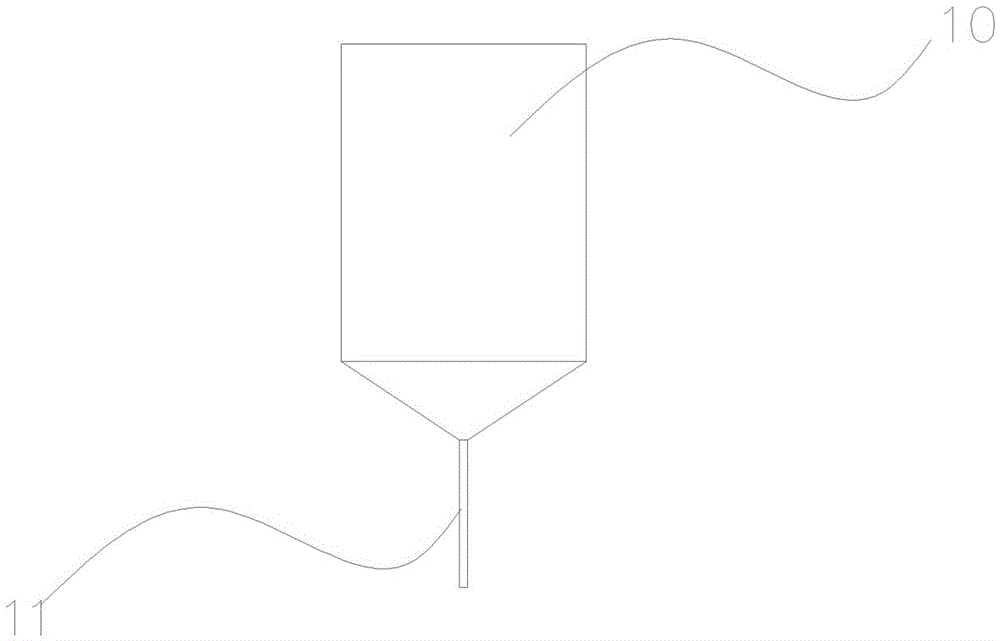

[0020] Such as Figure 1-2 As shown, a disposable lithium-ion battery with a heat-shrinkable plastic film shell includes a lithium-ion battery cell 1, a terminal positioning piece 2 and a cover plate 3 respectively provided at both ends of the lithium-ion battery cell 1, and a lithium-ion battery The inside of the cell 1 leads out and penetrates the terminal positioning sheet 2 and extends to the positive electrode guide pin 4 and the negative electrode guide pin 5 outside the terminal positioning sheet, and the heat-shrinkable plastic film casing 6 provided on the lithium-ion battery cell 1 . The terminal positioning piece 2 is provided with a liquid injection vent hole 7 . The liquid injection vent hole 7 is provided with a plug needle 8 for sealing the liquid injection vent hole 7 . The positive electrode guide pin, the negative plate guide pin 5 , and the liquid injection a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com