Plate packaging machine for pole plates of lead-acid batteries

A lead-acid battery and plate-packing machine technology, which is applied in lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve the threat of increasing glue pollution to human health, increase production costs of enterprises, and reduce work efficiency and other problems, to achieve the effect of eliminating pollution and threats to human health, improving production efficiency, and improving encapsulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

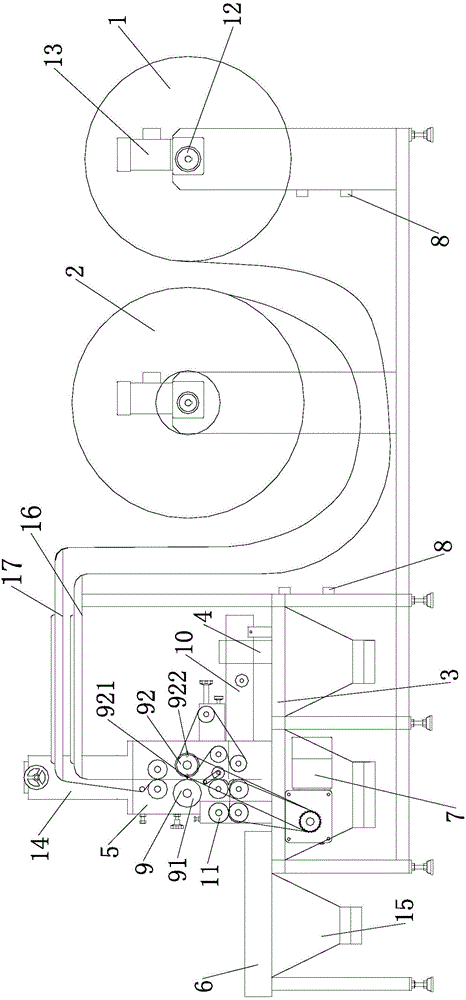

[0015] The present invention includes a glass fiber feeding mechanism 1, a PE partition feeding mechanism 2, a glass fiber feeding table 16, a PE partition feeding table 17, a working table 3, a plate feeding mechanism 4, a tape cutting head 5, and a plate receiving table 6 And the motor 7, the glass fiber feeding mechanism 1 and the PE partition feeding mechanism 2 are arranged on the right side of the workbench 3, and the glass fiber feeding mechanism 1 and the PE partition feeding mechanism 2 are respectively provided with a The photoelectric switch 8 of the height, the glass fiber feeding table 16 is below the PE partition feeding table 17, and is arranged on the side above the cutting head 5, and the plate feeding mechanism 4 is arranged on the rear side of the workbench 3, and the cutting machine The head 5 is composed of a tape cutting mechanism 9, a folding mechanism 10 and a pressing mechanism 11, the tape cutting mechanism 9, the folding mechanism 10, and the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com