Liquid cooling rack of miniature array device

A liquid-cooled rack and equipment technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve problems such as effective thermal management and maintainability, performance degradation or shutdown, and poor heat dissipation of high heat flow equipment at the same time, so as to shorten field maintenance Time, good heat dissipation, and good temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Describe the present invention below in conjunction with specific embodiment:

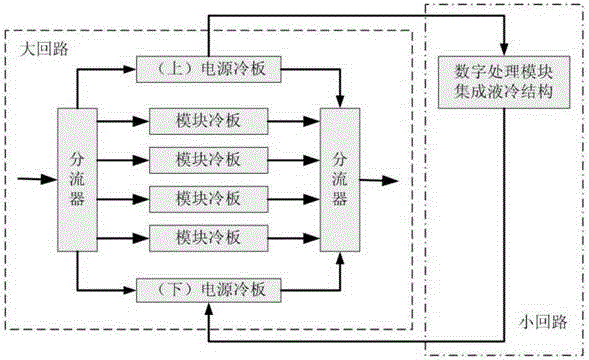

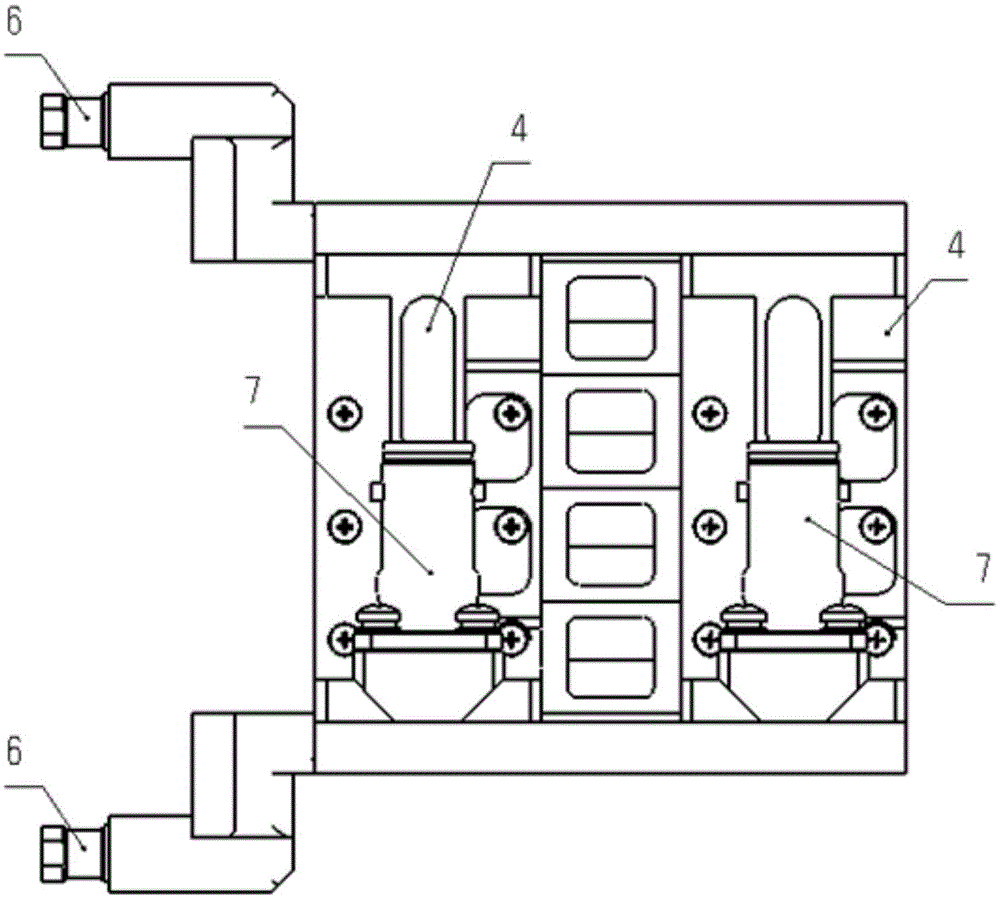

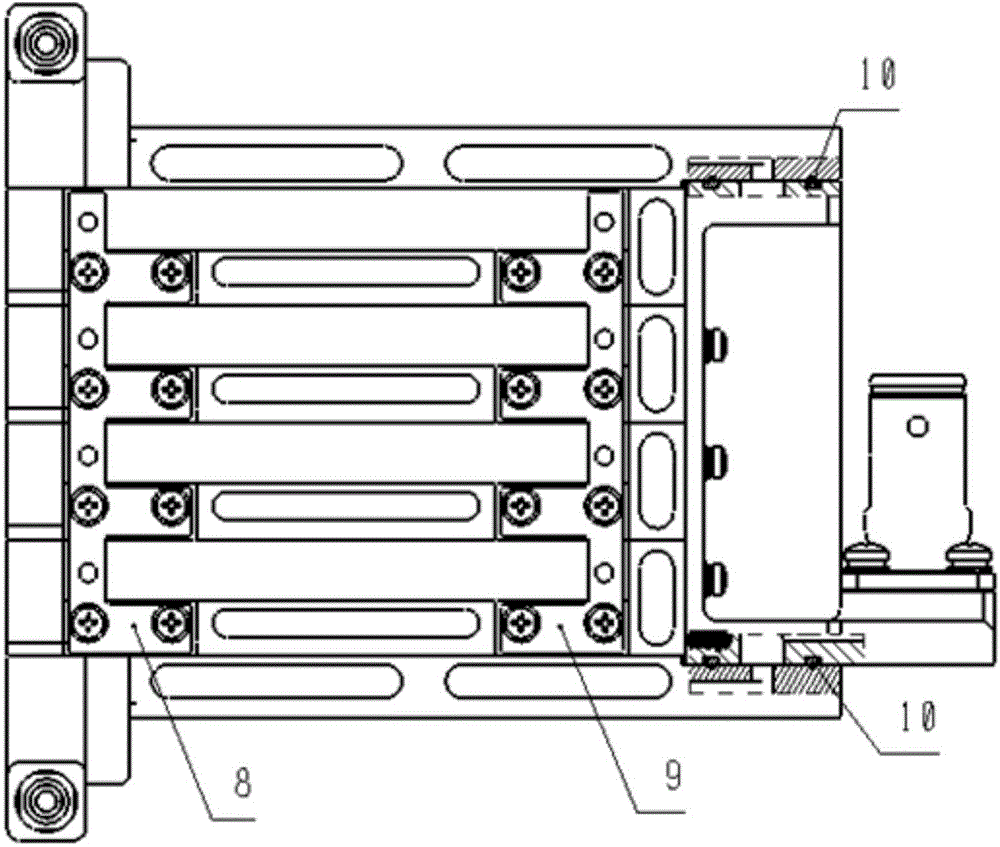

[0029] Refer to attached figure 2 ~ attached Figure 5 , the liquid-cooled rack of the miniaturized array equipment in this embodiment consists of four module cold plates, two power supply cold plates, two shunts, eight blind-mating liquid connectors, and two self-sealing blind-mating liquid connectors , two self-sealing bayonet liquid connectors and a guide frame.

[0030] The splitter is connected to the external coolant source through a self-sealing bayonet liquid connector, the front side splitter is used as the coolant inlet, and the rear side splitter is used as the coolant outlet; on the main channel of the splitter, there is a split cooling to the module cold plate and the power supply cold plate liquid flow channel. Taking the two splitters as the assembly reference, the cold plate of each module is connected horizontally to the two splitters simultaneously through two blind-mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com