Highly-efficient cooked wheaten food processing machine

A processing machine and pasta technology, applied in the fields of dough processing, food science, baking, etc., can solve the problems of easy breeding of bacteria, residues, and the inability to realize fully automatic pasta production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

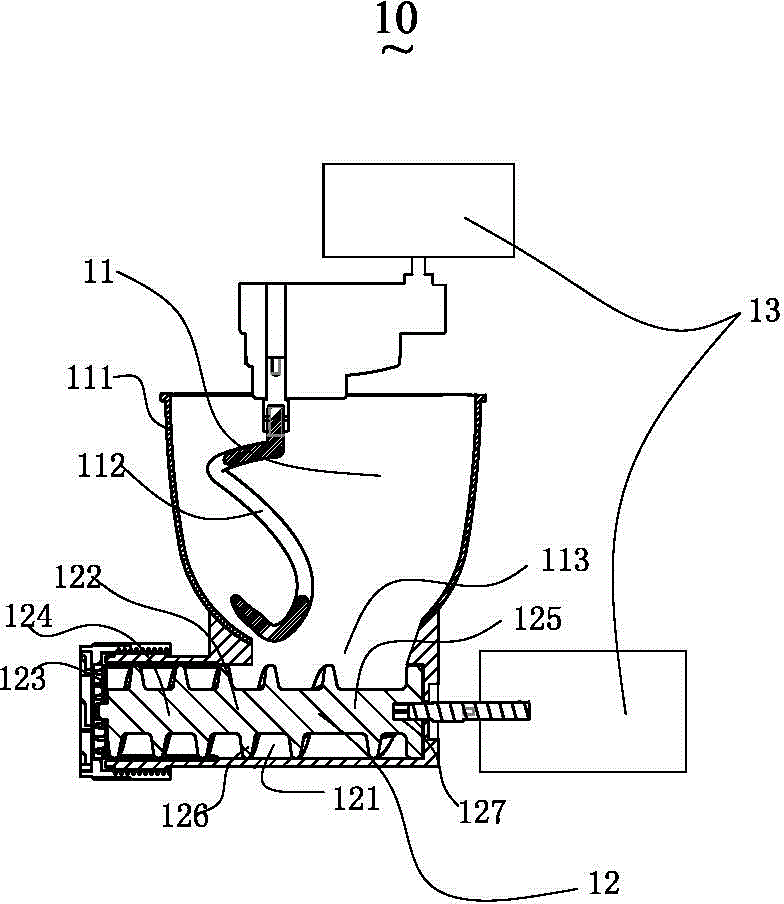

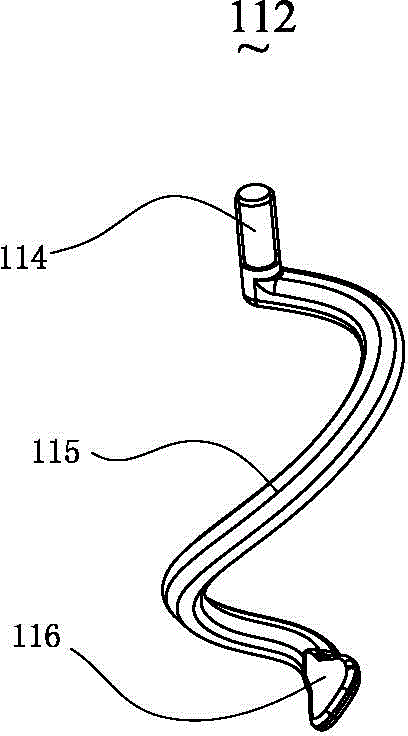

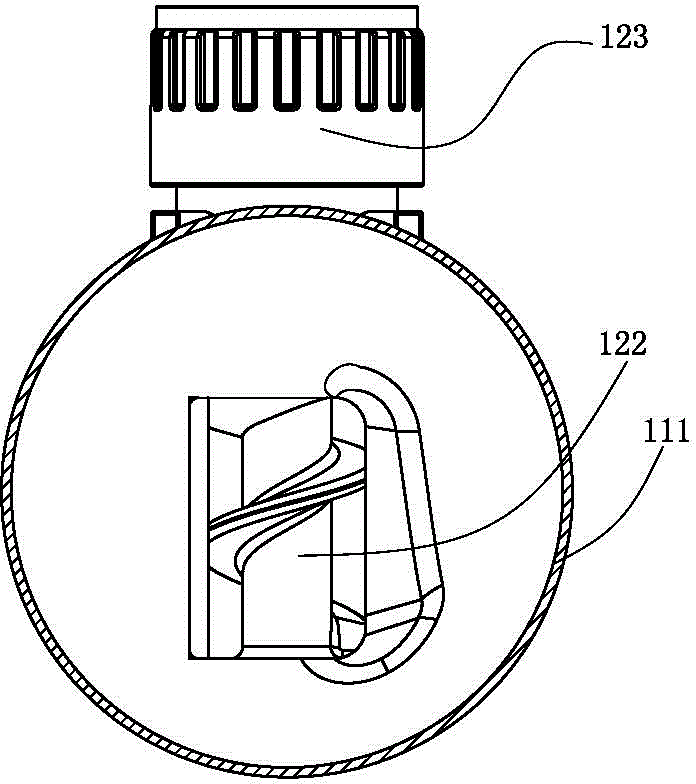

[0034] Please also refer to figure 1 , figure 2 and image 3 As shown, the first embodiment of a high-efficiency pasta processing machine of the present invention, the high-efficiency pasta processing machine 10 includes a stirring system 11 , an extrusion molding system 12 and a driving system 13 . The mixing system 11 includes a noodle bucket 111, a stirring rod 112, and the stirring rod 112 extends into the noodle bucket 111. The extrusion molding system 12 includes an extrusion chamber 121 , a screw 122 , and a molding head 123 . The bottom of the noodle bucket 111 is provided with an opening 113 communicating with the extrusion chamber 121 . The screw 122 includes a conveying part 124 and a feeding part 125 corresponding to the opening 113 , and an extruding screw 126 is arranged on the conveying part 124 and the feeding part 125 . The drive system 13 drives the stirring rod 112 and the screw rod 122 to rotate; the stirring rod 112 stirs the material in the noodle buc...

Embodiment approach 2

[0046] see Figure 4 As shown, the second embodiment of a high-efficiency pasta processing machine of the present invention differs from the first embodiment in that: the opening 113 is set on the side wall of the bottom of the noodle bucket 111, and the extrusion molding system 12 It is located on one side of the noodle bucket 111. In this way, when materials such as flour are put in, it can be effectively prevented from directly falling into the extrusion cavity 121 through the opening 113 . In addition, during the dough kneading stage, the dough rotates with the stirring rod 112 , and part of the dough enters the extrusion cavity 121 , and is also pushed back into the noodle container 111 by the screw rod 122 .

[0047] It can be understood that the extrusion molding system is arranged on one side of the noodle bucket, and the extrusion molding system and the noodle bucket can be axially parallel or perpendicular to the axis.

[0048] The remaining structures and benefici...

Embodiment approach 3

[0050] see Figure 5 As shown, the third embodiment of a high-efficiency pasta processing machine of the present invention differs from the first embodiment in that the rotation axis of the stirring rod 112 intersects the axis of the noodle bucket 111, that is, the The above-mentioned stirring rod 112 can be arranged obliquely in the noodle bucket 111.

[0051] In this implementation manner, other structures and beneficial effects are consistent with those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com