Ore separation system and method based on microwave heating and infrared array imaging

A microwave heating, infrared array technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

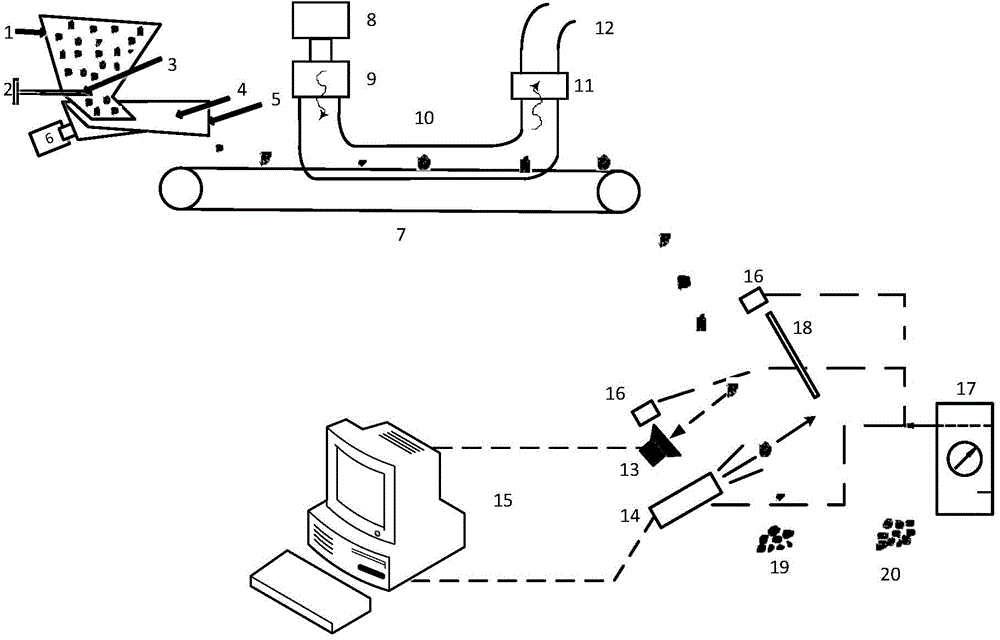

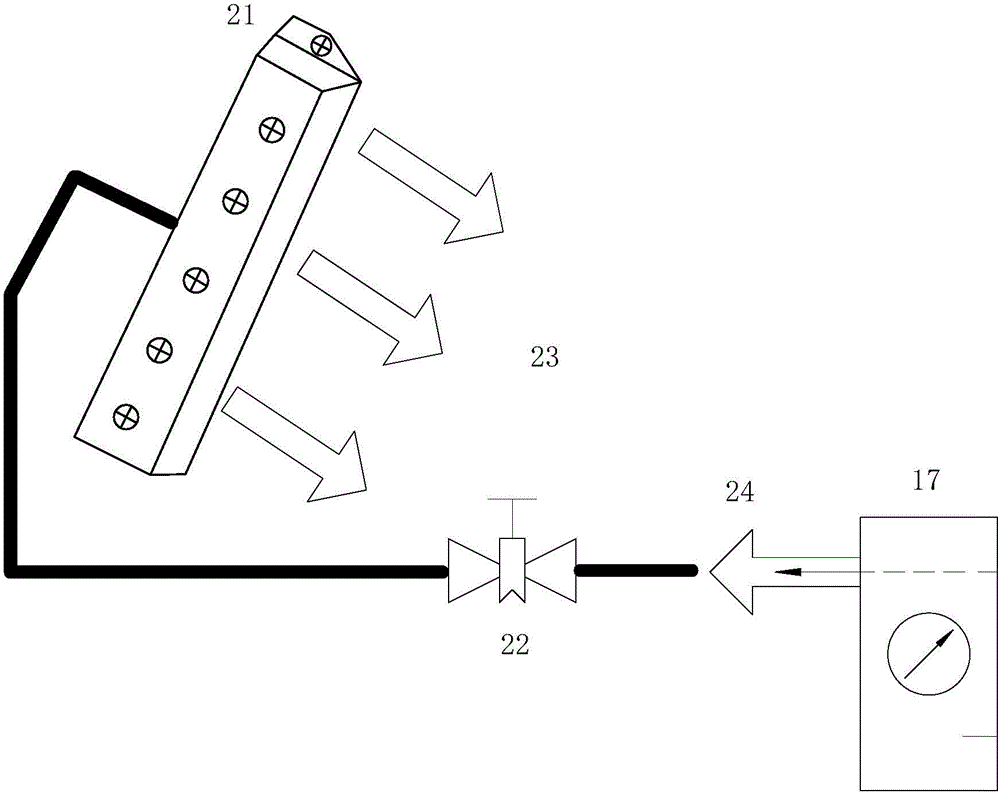

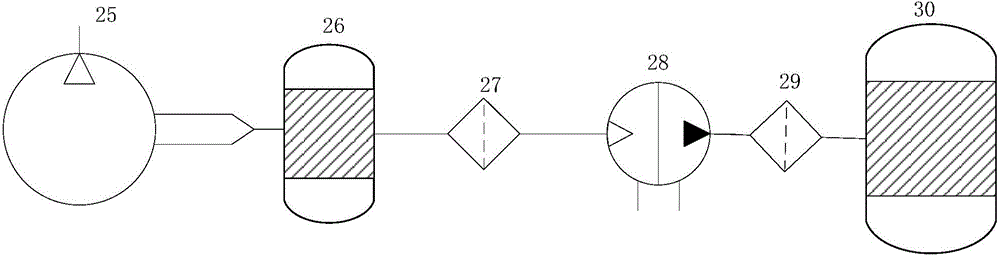

[0035] Such as Figure 1-3 As shown, the ore sorting system based on microwave heating and infrared array imaging includes:

[0036] Vibrating feeder, used to transport the raw ore particles to be selected to the conveyor belt;

[0037] Such as figure 1 As shown, the vibrating feeder includes a silo 1, the outlet at the lower end of the silo is located above one end of the chute 4, one end of the chute 4 is installed on the vibrating motor 6, and the discharge port 5 at the other end of the chute 4 corresponds to the X-ray detection device. The exit of the lower end of the warehouse 1 is provided with a gate 3 inserted horizontally therein to adjust the size of the opening, and the gate 3 is connected with the hand wheel 2 . Adjust the position of the gate 3 to change the feeding amount of the vibrating feeder.

[0038] The raw ore particles to be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com