Double swing arm adjustable position melt taking injection machine

A technology of double swing arm and injection machine, which is applied in the field of semi-solid metal processing, can solve the problems of large model, difficulty in accurate quantification, and insufficient adaptability of the processing site, and achieves a small footprint and space, and can be used for injection. The effect of accurate metal melting quantitative and saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

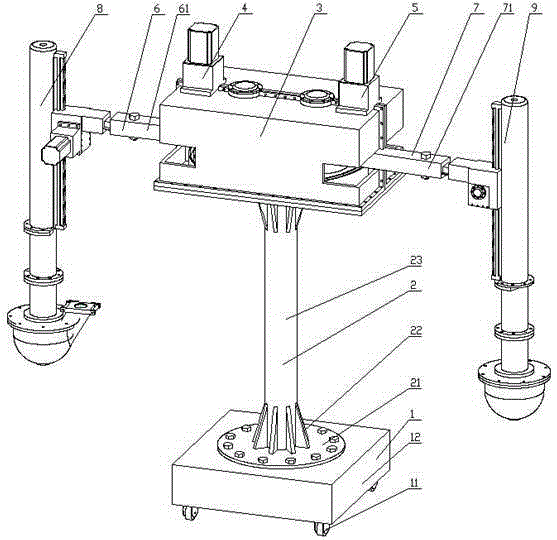

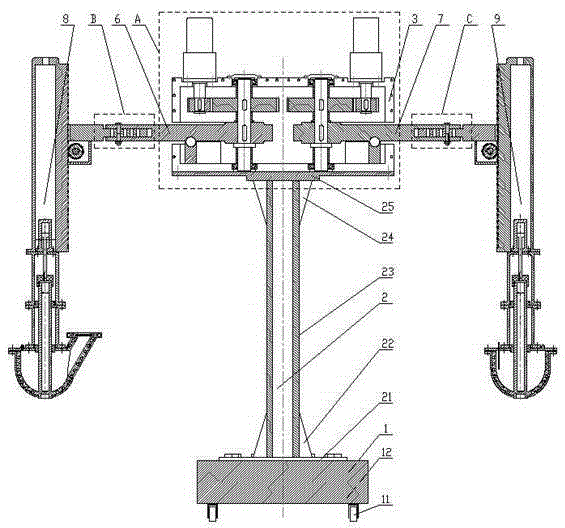

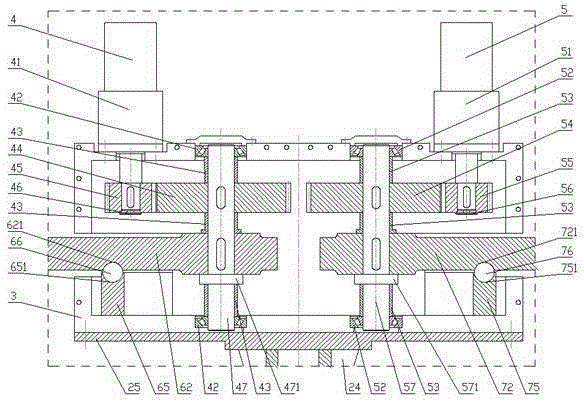

[0031] as attached Figure 1~5 As shown, the double-swing arm adjustable melt taking and pouring machine according to the present invention mainly includes the overall moving assembly 1 of the device, the main support column assembly 2, the power platform 3, the left power driving assembly 4, and the right power driving assembly 5. Left swing arm assembly 6, right swing arm assembly 7.

[0032] The overall moving assembly 1 of the device is mainly composed of a universal wheel 11 and a base 12. The universal wheel 11 is installed on the bottom of the base 12 to support the base 12 and the entire body. Under the action of the universal wheel 11 , the entire machine body can move in any direction along the horizontal ground, which enhances the adaptability to the current production and strengthens the flexibility of the position adjustment of the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com