Electronic ignition based self-propagating welding electrode

An electronic ignition and self-propagating technology, applied in welding equipment, welding medium, welding equipment, etc., can solve problems such as safety accidents, fuse leakage, etc., and achieve the effects of improving safety, avoiding burning, and compact and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

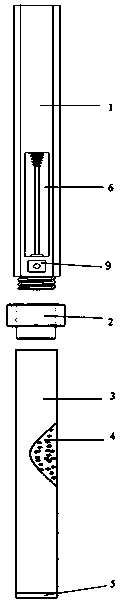

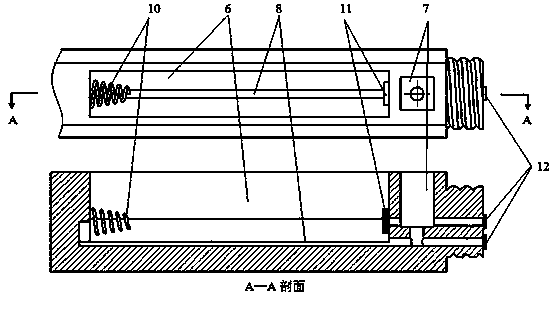

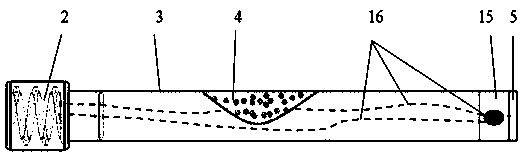

[0027] The self-propagating welding rod based on electronic ignition includes a handle 1, a plug 2 and a drug tube 3. The connecting end of the handle 1 has an external thread, and is connected with the plug 2 through threads, and the boss of the plug 2 is connected to the drug tube. The tubes 3 are fixedly connected coaxially, and the other end of the drug tube 3 is sealed with a packaging plug 5;

[0028] The handle 1 has a battery slot 6 and a switch slot 7, and the two ends of the battery slot 6 are respectively a spring 10 and a metal sheet 11. Point 12 is connected, there are two corresponding second contacts 14 on the plug 2, when the handle 1 is connected to the plug 2, the first contact 12 is in contact with the second contact 14;

[0029] There is a 3-5mm long ignition section 15 at one end of the sealing plug 5 of the drug tube 3, and welding flux 4 is filled between the ignition section 15 and the plug 2, and the drug head part of the electric ignition head 16 is w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com