Airbag-type rapid pressure increase or decrease control system in elevator car

A technology of elevator car and control system, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of long transition time, no specific description, and insufficient air pressure changes, and achieves increased air pressure, The effect of reducing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

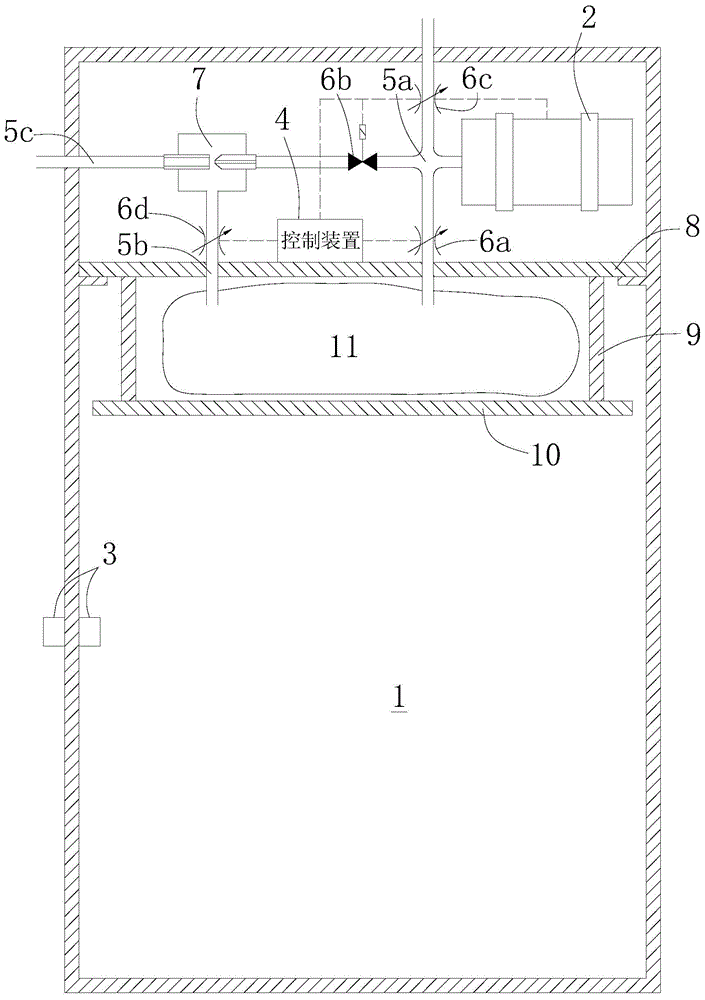

[0052] image 3 It shows the structure diagram of the air pressure control system in the elevator car involved in the present invention, which is used to control the air pressure in the elevator car 1 . The air pressure control system in the elevator car is set on the top of the elevator car 1. The system has: a nearly airtight elevator car 1 with only a small amount of air leakage during the up and down running of the elevator. Moreover, the elevator car 1 is in the During the operation, it only stops at two places, the ground floor and the top floor, and does not stop at the middle floor; a gas generator 2 is arranged on the top of the elevator car 1, and the gas generator can quickly generate a large amount of gas in a short time. Gas is generated by a blower or an air compressor, or by a chemical reaction; the piping group 5 has a right end connected to the gas generator 2, a lower end connected to the air bag 11, and a left end connected to the vacuum generator 7 Air inl...

Embodiment 2

[0064] Figure 4 It shows the structural diagram of the air pressure control system in the elevator car according to the present invention, and controls the air pressure in the elevator car 1 . The air pressure control system in the elevator car includes: a nearly airtight elevator car 1, there is only a small amount of air leakage during the up and down running of the elevator, and the elevator car 1 is only between the ground floor and the top floor during operation Stop everywhere, not intermediate floors. Furthermore, the elevator car 1 has an additional volume chamber 13 . The volume chamber 13 is divided into an upper volume chamber 13a and a lower volume chamber 13b by a piston 12 closely matched with the wall surface of the volume chamber. The device 2 is connected through the connecting pipe 5g of the lower volume chamber. The air between the upper and lower volume chambers is isolated by the piston 12 and cannot communicate with each other. There is also a stopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com