Preparation method of niti fiber reinforced intermetallic compound-based matrix composite material for vibration and noise reduction

An intermetallic compound and fiber reinforced technology is applied in the field of preparation of laminated energy-absorbing materials, which can solve the problems of poor impact resistance, inability to apply the working environment of bearing capacity, low strength, etc., and achieve the effect of toughening and increasing damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

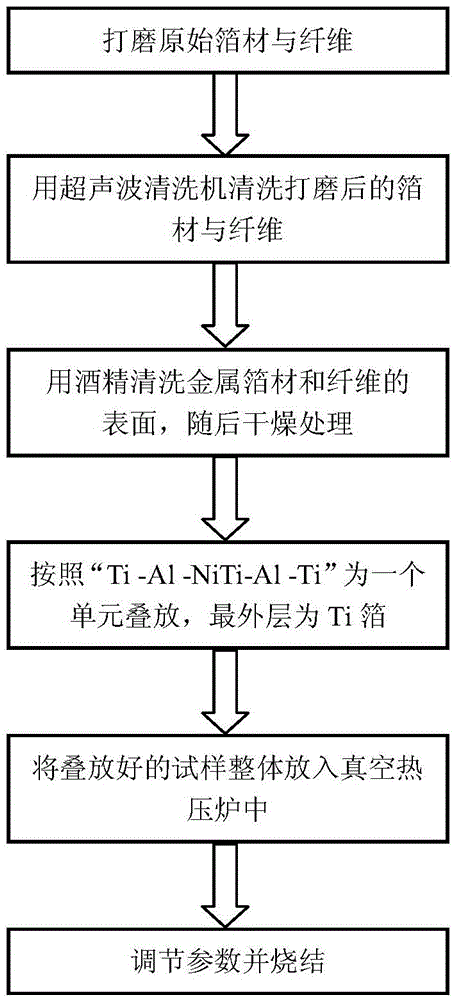

[0031] Cut the 0.5mm Ti foil and 0.9mm Al foil into 100mm×100mm square foil, and cut the NiTi alloy fiber into 10mm long fiber, and use sandpaper to polish and clean the original metal foil and fiber surface to remove scale and expose Clean the surface, then clean the polished Ti foil, Al foil, and NiTi alloy fiber with an ultrasonic cleaner for 20 minutes, and finally clean the surface of the metal foil and fiber with alcohol to remove the remaining oxide particles and impurities. After drying treatment, stack two units according to "Ti foil-Al foil-NiTi fiber-Al foil-Ti foil" as a unit, the distance between fibers is 1mm, and the uppermost and lowermost layers are Ti foil.

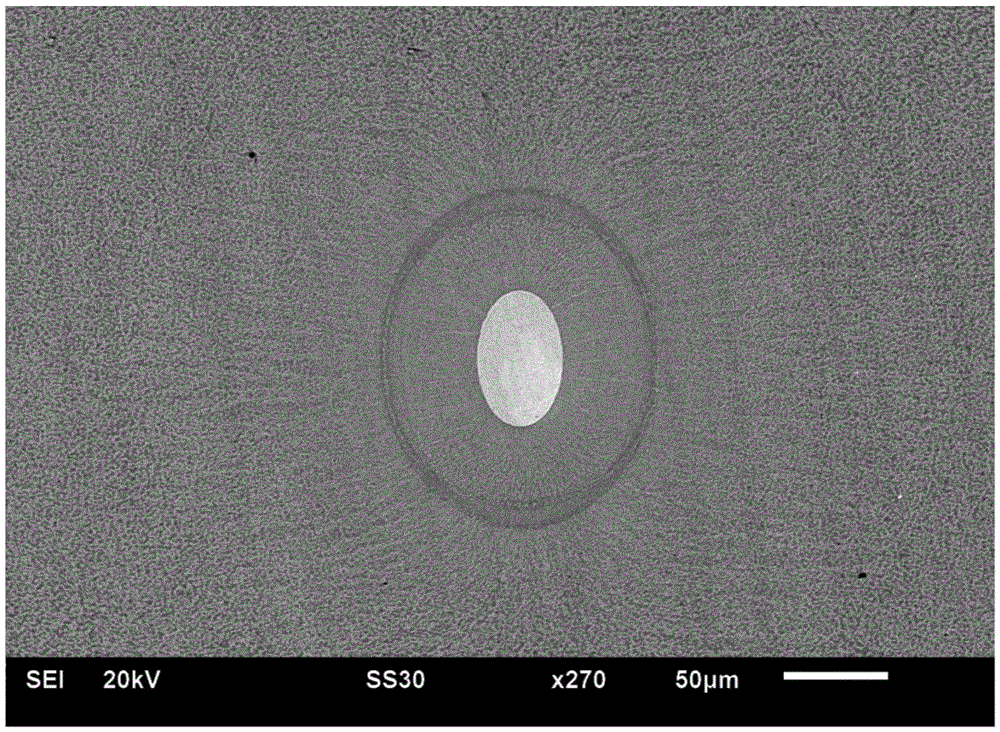

[0032] Put the arranged metal foil blanks into a vacuum hot-press furnace for composite material preparation: in 10 -3 Under a low vacuum of Pa, raise the temperature to 640°C for 0.5h at a heating rate of 10°C / min, then raise the temperature to 660°C at a heating rate of 2°C / min and hold for 0.5h, and t...

Embodiment 2

[0036] The pretreatment method of raw material is the same as embodiment 1, and used Al foil thickness is 1.1mm, and used process parameter is: at 10 -3 Under a low vacuum of Pa, raise the temperature to 640°C at a heating rate of 10°C / min and keep it for 0.5h, then raise the temperature at a heating rate of 2°C / min to 660°C and keep it for 0.5h, and then at a heating rate of 1°C / min Raise the temperature to 675°C for 1.5h, then cool down to 400°C at a rate of 2°C / min. Maintain a pressure of 2MPa during the heating process, apply a pressure of 1MPa during the 675°C holding stage, and maintain a pressure of 2MPa during the cooling stage.

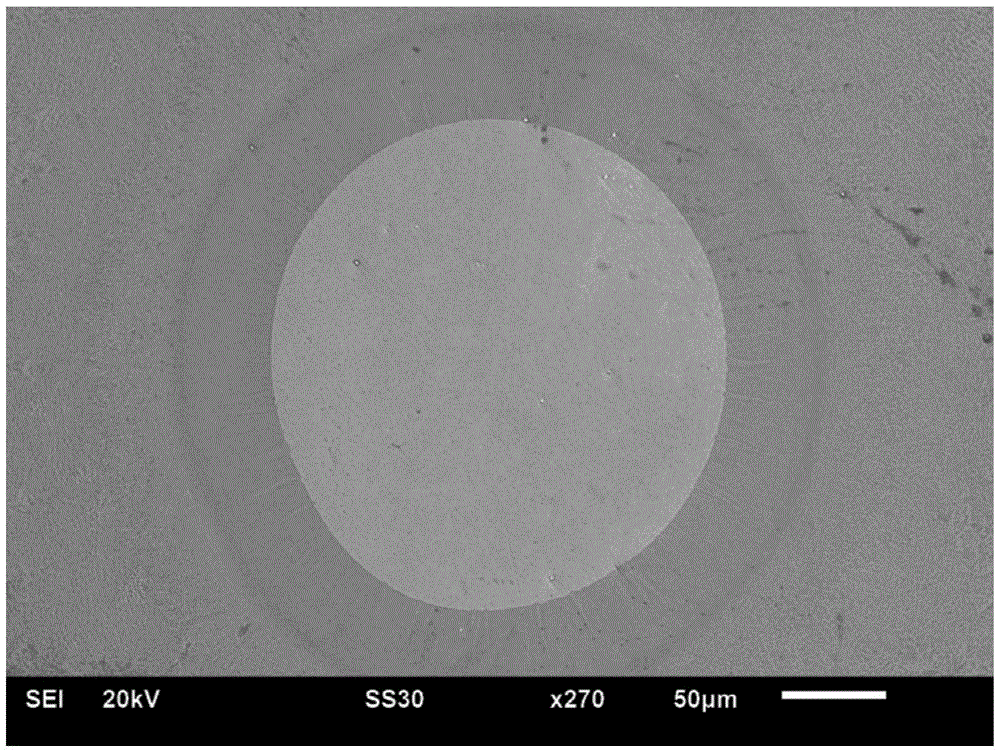

[0037] The NiTi fiber reinforced Ti / Al that this embodiment gains 3 Scanning electron micrographs of Ti layered composites (attached image 3 ) It can be seen that when the temperature decreases, the holding time decreases, the Al foil thickens, and the pressure decreases, the NiTi fiber and Al 3 The bonding part of the Ti matrix also has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com