Wind turbine assembly line oil change system and method

An assembly line wind turbine technology, applied in wind power generation, wind engines, motors, etc., can solve the problems of bulky size, restrictions on popularization, security threats, etc., and achieve the effect of practical system structure, novel operation and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

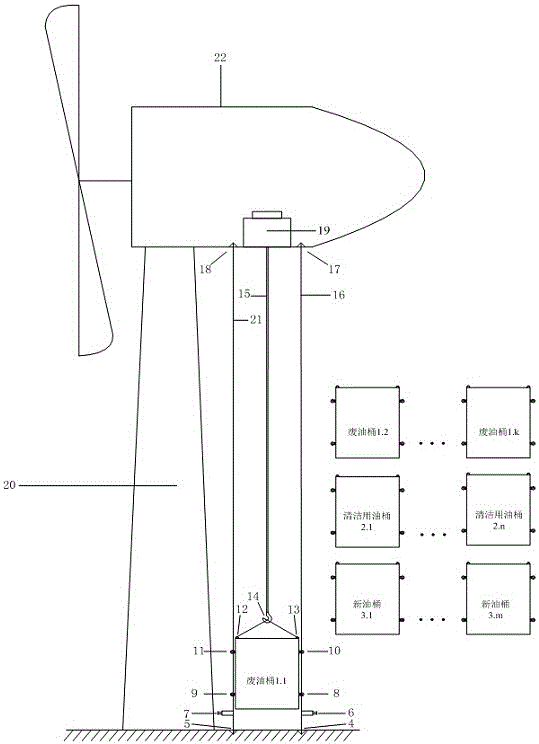

[0028] see figure 1, the wind turbine assembly line oil change system includes high-altitude equipment cabin (22), waste oil barrels (1.1, 1.2, ..., 1.k), cleaning oil barrels (2.1, 2.2, ..., 2.m) and new oil barrels (3.1, 3.2,..., 3.n), characterized in that: a hoist (19) is installed next to the oil change target box in the high-altitude equipment cabin (22), and the hoist (19) has a drooping The lower end of root hook rope (15) connects a suspension hook (14); Described waste oil barrel (1.1,1.2,...,1.k), cleaning oil barrel (2.1,2.2,...,2.m) and new Oil barrel (3.1, 3.2,..., 3.n) top has hook ring I (12) and hook ring II (13) and connects a rope and can hang on the suspension hook (14), and its barrel wall Safety ring I (8) and safety ring II (10) are fixedly installed on one side, and safety ring III (9) and safety ring IV (11) are fixedly installed on the other side, with safety wire I (16) and safety wire II (21) can pass through four safety rings (8,9,10,11) respecti...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0031] The waste oil barrels (1.1, 1.2, ..., 1.k) are used to specially accommodate the waste oil in the oil change target box, which can be changed according to the size of the system scale k; the cleaning oil barrels (2.1, 2.2, ... , 2.m) is used to specially arrange the cleaning oil for cleaning and changing the target box body, which can be changed according to the size of the system scale n; the new oil barrel (3.1, 3.2, ..., 3.n) is used to specially arrange the replacement The new oil of oil target casing can change according to the size of system scale m; Described safety cable I (16) and safety cable II (21) are installed in parallel between high-altitude equipment compartment (22) and the ground, and have A certain pulling force ensures the safety during the oil change process. In case of an accident, the oil drum is detached from the hook, and the falling positio...

Embodiment 3

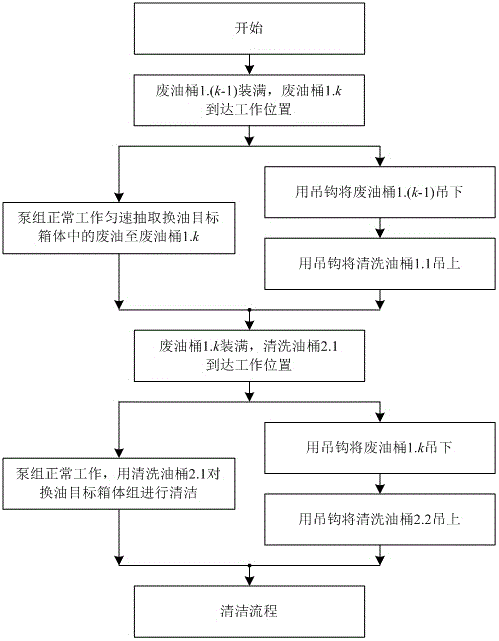

[0033] This wind turbine assembly line type oil change method adopts the above-mentioned system for oil change, and is characterized in that it includes the following operation process: waste oil extraction process, waste oil extraction process ends and cleaning process starts alternate process, cleaning process, cleaning process ends and new delivery process Alternate flow of oil process start and delivery of new oil flow.

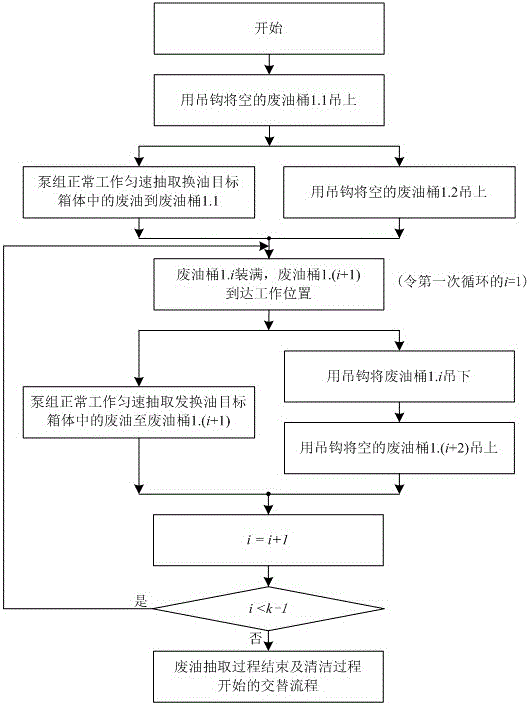

[0034] see figure 2 , Waste oil extraction process: First, hang the empty waste oil barrel (1.1) with a hook, then turn on the pump unit to work normally and extract the waste oil in the oil change target box to the waste oil barrel (1.1), where it is extracted Use the hook to lift the empty waste oil barrel (1.2) at the same time as the waste oil; then the waste oil barrel (1.1) is full and the waste oil barrel (1.2) reaches the working position, and the pump unit is started to work normally and extract the oil change target The waste oil in the box go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com