Throttling method for water flow heating device

A heating device and water flow technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of increased power consumption, inconvenient use, increased pressure device and pipeline costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

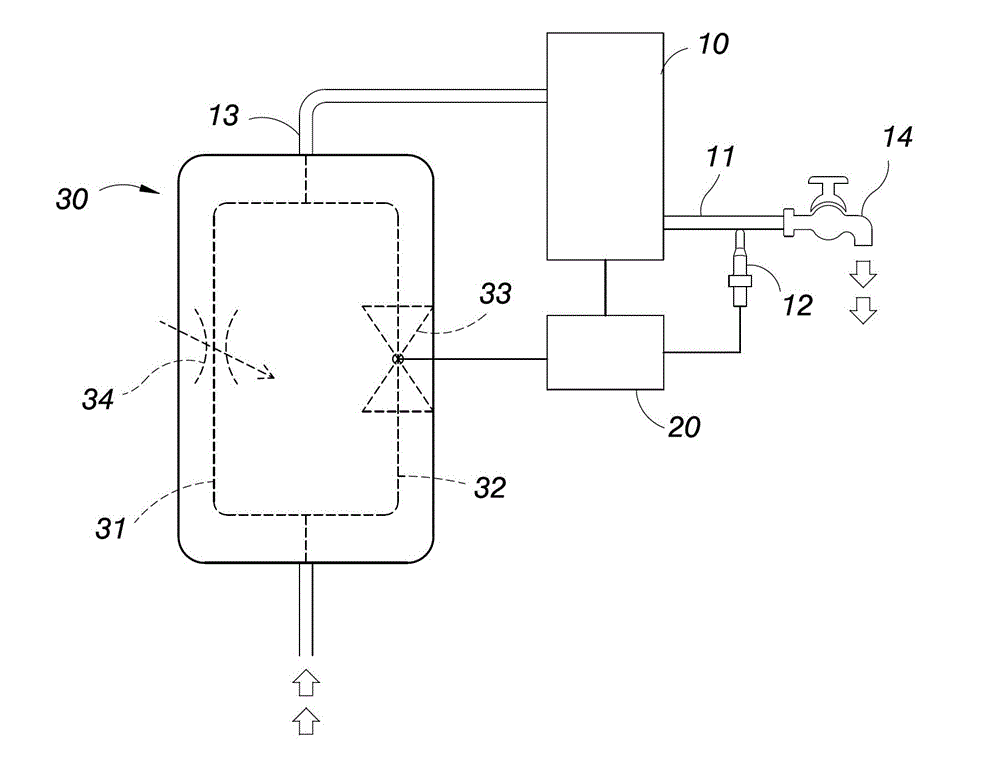

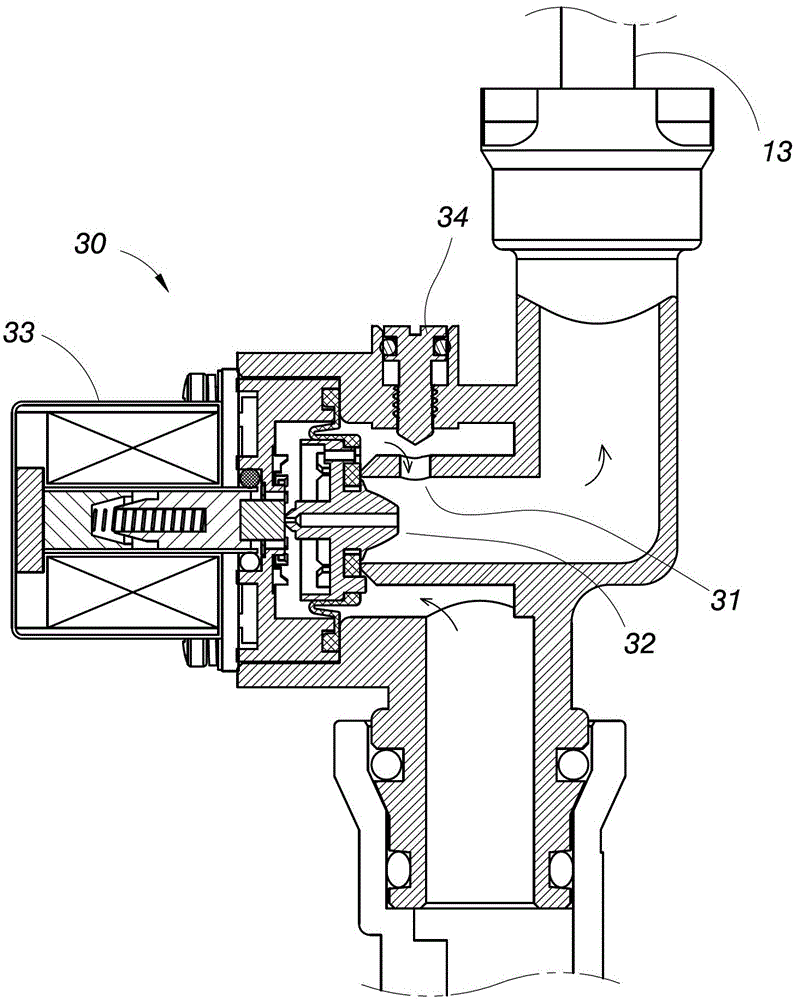

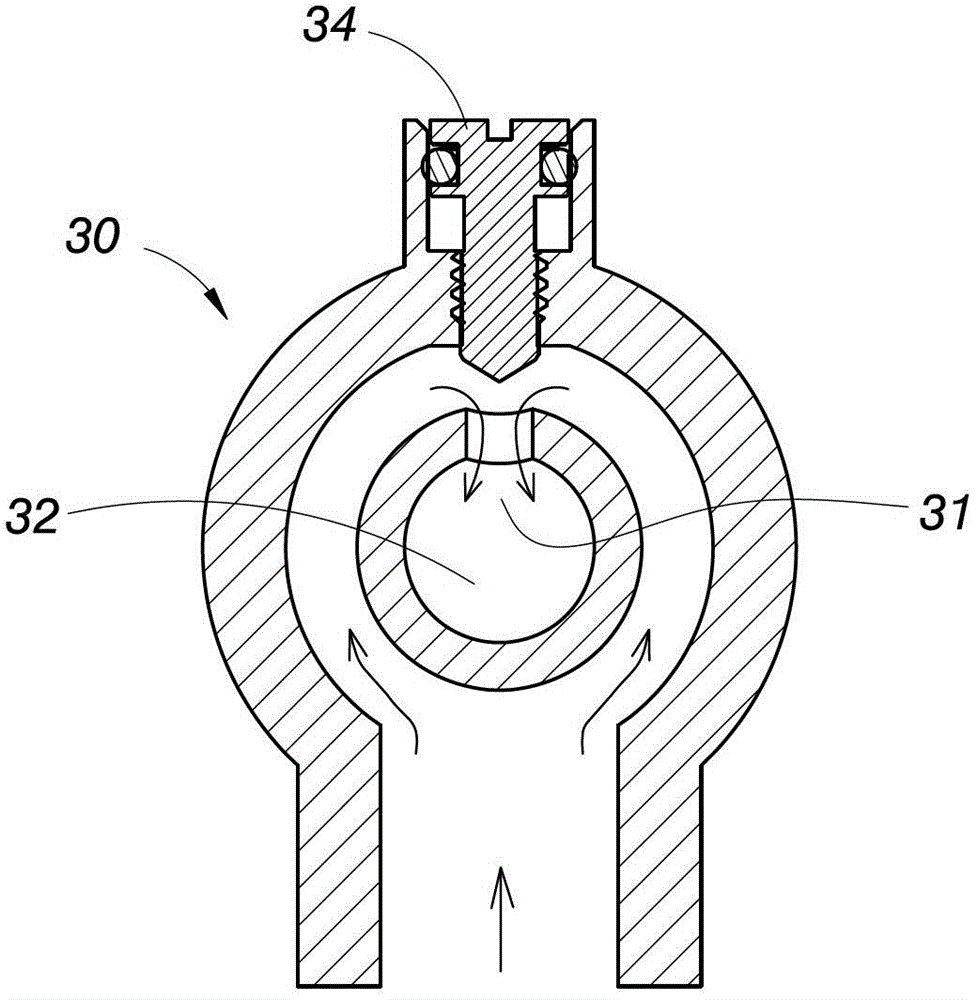

[0039] Such as Figure 2 to Figure 4 As shown, the electric valve 33 of the restrictor 30 can be a two-stage self-holding solenoid valve that closes or opens the large flow passage 32, while the small flow passage 31 is a valve set on the restrictor 30. The bypass hole that bypasses the large flow passage 32 and the electric valve 33 and is always open keeps the small flow passage 31 permanently open no matter whether the large flow passage 32 is closed or opened.

[0040] In order to adjust the flow depending on the air temperature and water pressure conditions, a regulating device 34 that can adjust the water flow of the small flow channel 31 can be further set on the restrictor 30, so that the aforementioned cold water discharged can be further restricted. An adjusting device 34 that can adjust the water flow of the small flow channel 31 can be further provided on the restrictor 30, so that the aforementioned cold water discharged can be further restricted.

[0041] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com