Color film substrate, liquid crystal module and touch display device

A color film substrate and liquid crystal module technology, which is applied in optics, instruments, electrical digital data processing, etc., can solve the problems of unable to monitor FPC binding status, blind binding, and detection of FPC binding status, so as to improve the process quality Yield, avoiding quality accidents, and reducing the effect of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

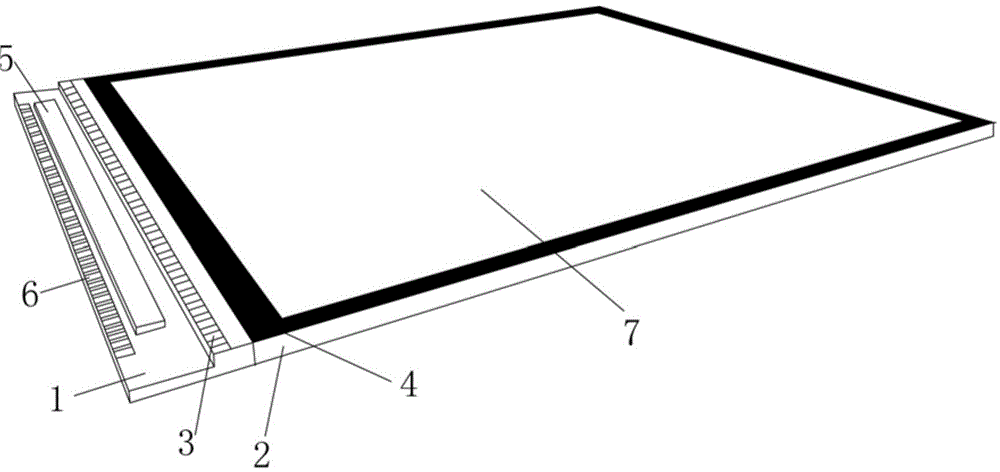

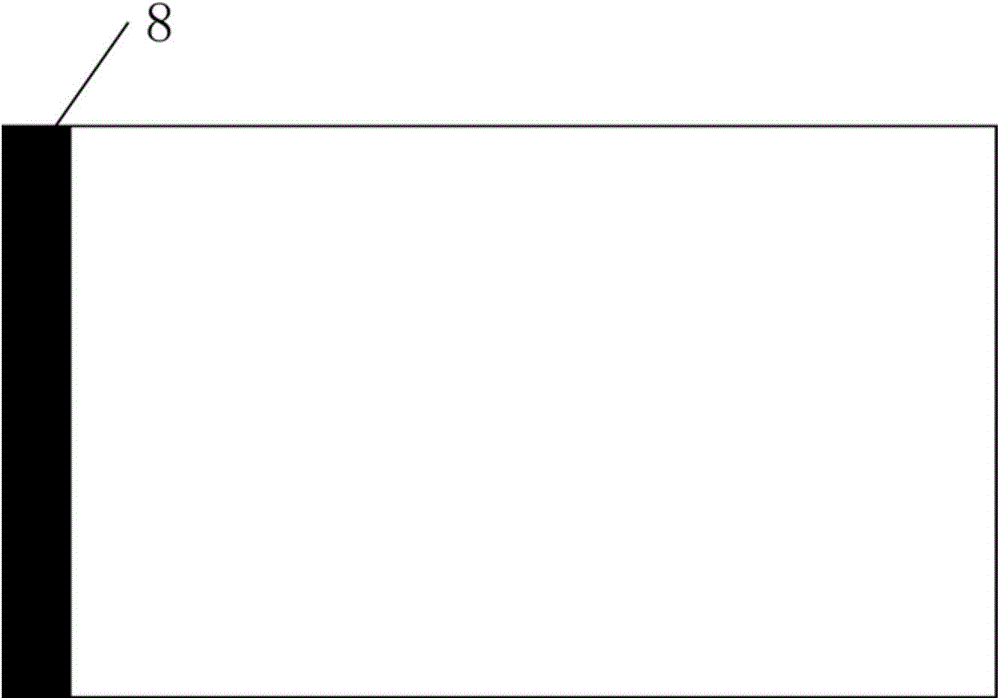

[0020] Such as figure 1 As shown, according to the first embodiment of the present invention, a color filter substrate 2 is provided, and the color filter substrate 2 includes a flexible printed circuit (TFPC) binding area 3 for touch control and a black matrix BM area 4 .

[0021] Wherein, the TFPC binding area 3 is used for binding the flexible printed circuit for touch control, and its bottom is transparent, while the BM area 4 is used for light shielding.

[0022] Wherein, the TFPC binding area 3 and the BM area 4 are two mutually independent areas, and the two areas have no overlapping area or a partial overlapping area; and, the bottom of the flexible printed circuit binding area for touch is transparently set .

[0023] Specifically, the color filter substrate 2 may be a glass substrate, and the bottom of the TFPC binding region 3 may be transparent glass.

[0024] In fact, it is equivalent to increasing the length of the original color filter glass substrate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com