Low maintenance nozzle mixer unit for roll nip lubrication

一种轧辊间隙、混合器的技术,应用在轧辊的装置领域,能够解决损坏轧制带材表面品质、润滑失效等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

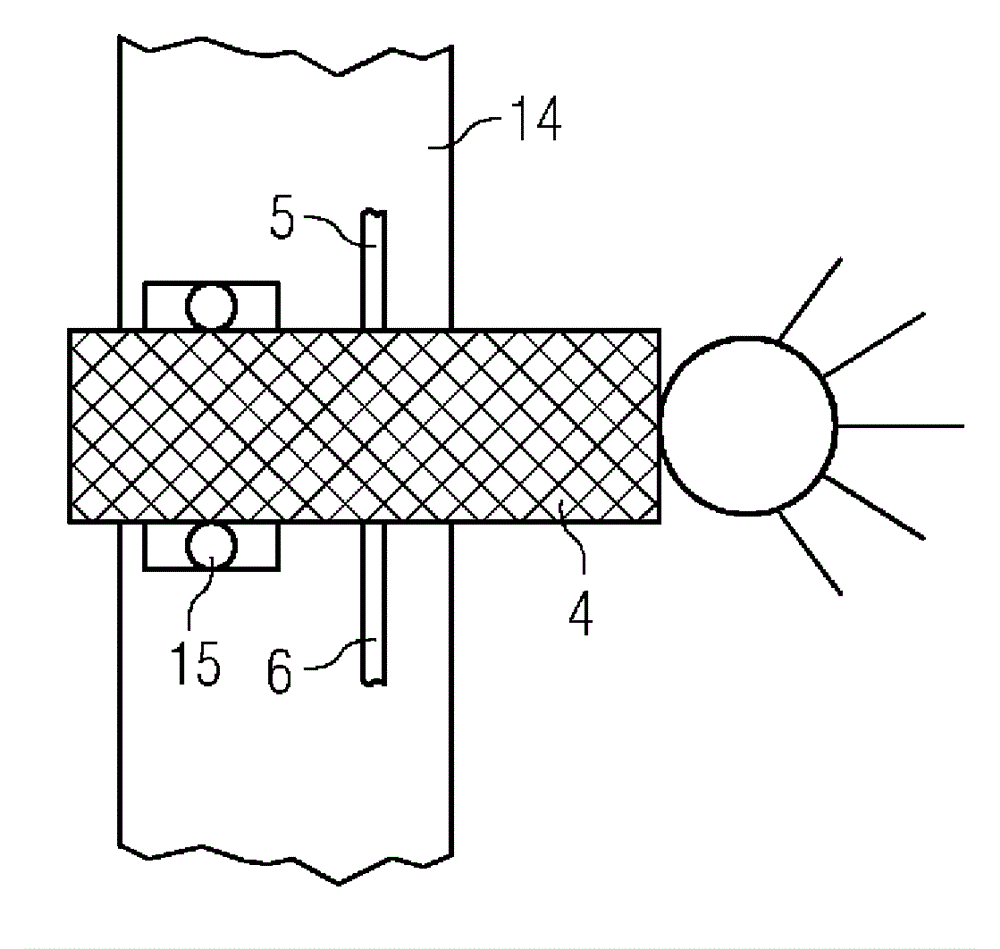

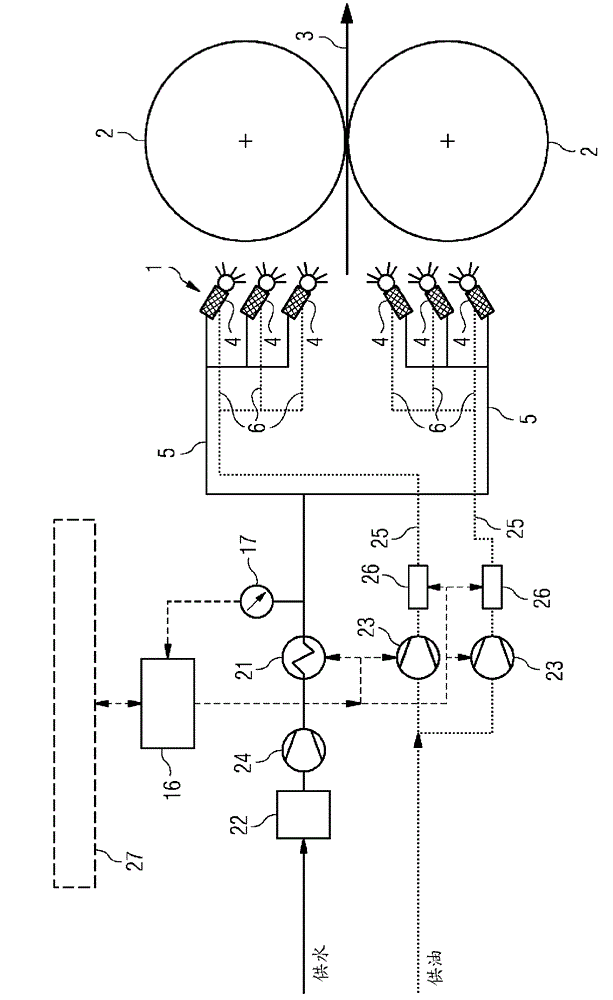

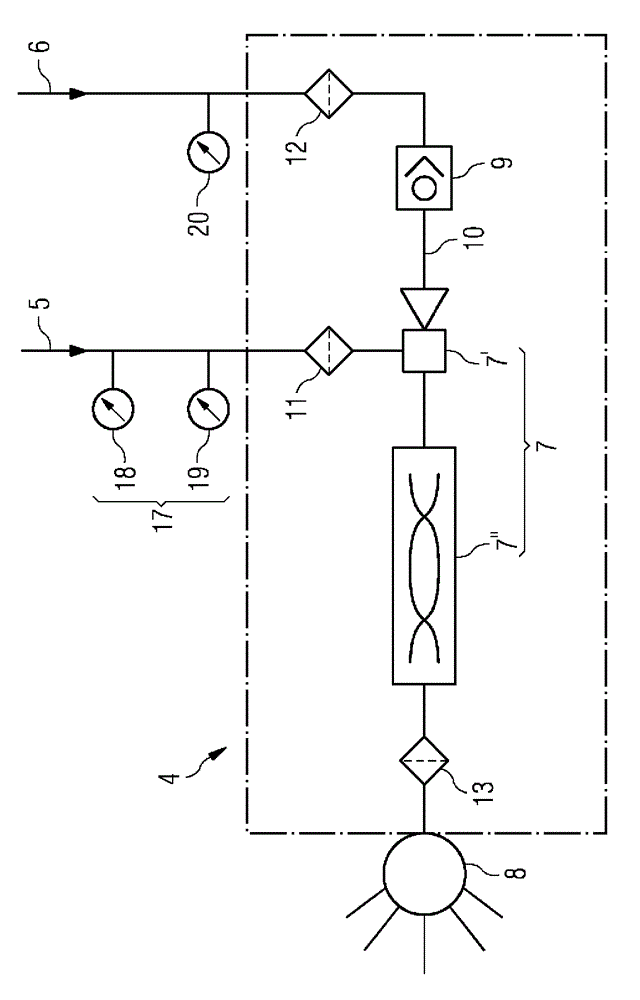

[0022] figure 1 A block diagram of roll gap lubrication according to the invention is shown. Reference numeral 1 designates a mixing and spraying device, which is formed from a plurality of nozzle mixer units 4 . An emulsion of water and oil is introduced into the roll gap by means of the nozzle mixer unit 4 . This is done by means of the nozzles 8 of the nozzle mixer unit 4 (see figure 2 ) spray the emulsion onto the work roll 2 and / or onto the surface of the rolled strip 3 .

[0023] Each nozzle mixer unit 4 is supplied with water via a first supply line 5 and with oil via a second supply line 6 . Nozzle and mixer form a structural unit.

[0024] The oil supply lines to the mixing and injection device (1) lead in a line bundle (25). The oil lines are supplied by individual pump elements and / or via oil valves, which operate on and off or continuously. In this way, a uniform or individual oil flow loading can be used for each nozzle mixer unit, eg also 0% loading.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com