Aluminum ingot continuous casting mold

A mold and continuous casting technology, which is applied in the field of aluminum ingot continuous casting molds, can solve the problems of no connection parts and delays in production, and achieve the effects of convenient casting, reduced maintenance, and reduced frequent cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

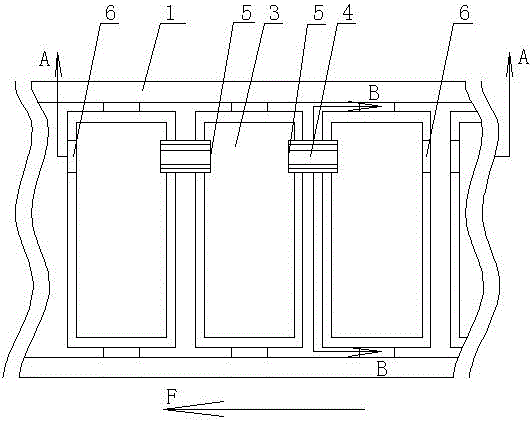

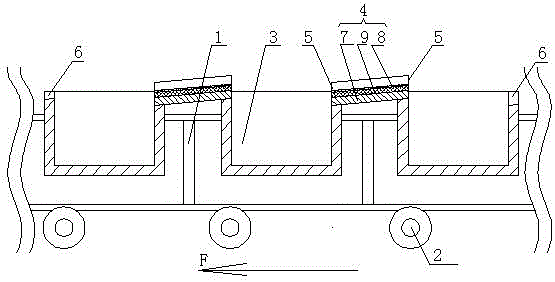

[0015] Such as figure 1 , 2 As shown in , 3, a continuous casting mold for aluminum ingots includes a connector 1, wheels 2 are arranged below the connector, and a plurality of individual molds 3 are arranged on the connector, and the individual molds are arranged on the connector in parallel. The feature is that there are receiving grooves 4 between adjacent mold individuals, openings 5 are provided at both ends of the receiving grooves, and the two openings are respectively on the adjacent mold individuals.

[0016] When casting like this, the aluminum lock just flows in the accepting groove the inside, can not flow in other places, has the advantage of the present invention.

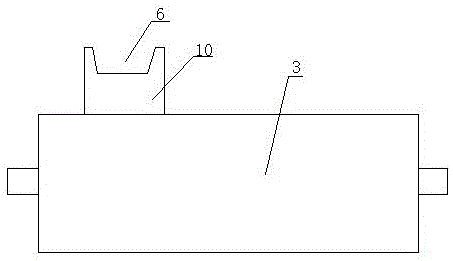

[0017] Further, the individual mold has a recess 6, and the receiving groove is placed in the recess, so that the individual mold has a fixed place to prevent it from being placed in an orderly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com