A kind of carbon nitride and preparation method thereof

A technology of carbon nitride and azacytosine, which is applied in the field of functional nanometers, can solve the problems of time-consuming and cumbersome steps, and achieve the effect of simple process and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

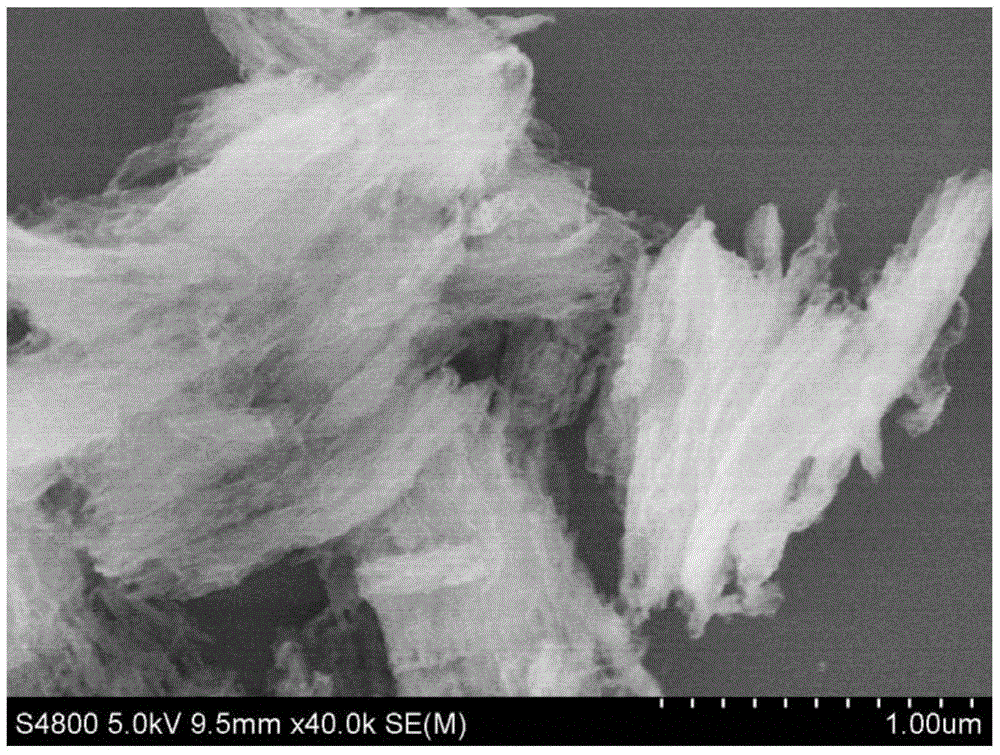

[0020] Example 1, weigh 2 grams of 5-azacytosine, put it into a magnetic boat, then heat it in nitrogen with a tube furnace at a rate of 0.°C / min, and heat it at 500 degrees for 2 hours. Get carbon nitride. figure 1 Scanning electron micrographs of carbon nitride prepared for this example. Depend on figure 1 It can be seen that uniform pores are distributed on the surface of carbon nitride.

Embodiment 2

[0021] Example 2, weigh 2 grams of 5-azacytosine, put it into a magnetic boat, then use a tube furnace to heat in nitrogen at a rate of 10°C / min, and heat at 500°C for 2 hours to obtain carbon nitride.

Embodiment 3

[0022] Example 3, weigh 2 grams of 5-azacytosine, put it into a magnetic boat, then use a tube furnace to heat in nitrogen at a rate of 2°C / min, and heat at 700°C for 2 hours to obtain carbon nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com