The profiling repair method of the blade tip wear of the compressor rotor blade

A technology for a compressor rotor and a repair method, which is applied in the direction of metal material coating process and coating, can solve the problems of large thermal influence of the substrate, prone to undercut, complex compressor rotor blade profile, etc., and achieves low repair cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

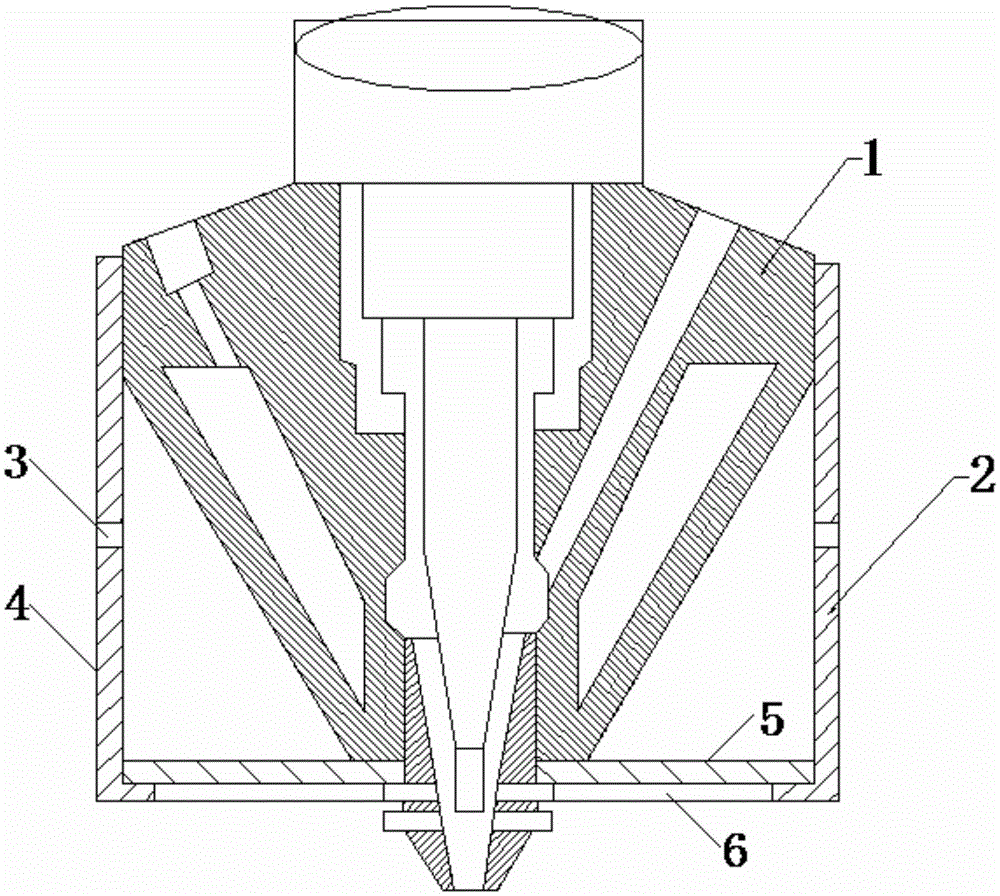

[0015] See figure 1 . The material of the fifth-stage rotor blade of the engine's high-pressure compressor is GH4169, and the blade tip wear length is 0.5mm. According to the compressor rotor blade material is a nickel-based alloy, IN178 powder is used as the cladding material, and the powder particle size is (-100~+325) mesh. The non-environmental box-protected laser cladding technology is used to repair the worn parts of the high-pressure compressor rotor blade tip. The laser cladding is performed by coaxial powder feeding in an atmospheric atmosphere, and an argon protective gas cover 4 with a diameter of about 200 mm and a protective gas sleeve 2 is arranged outside the main body 1 of the coaxial powder feeding laser cladding nozzle. The protective gas cover 4 is provided with a radial argon inlet 3 on the cover body, the bottom is provided with a porous copper sheet 5, and the nozzle extends out of the cover from the bottom porous copper sheet 5, and the bottom of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com