Screw-pump oil production technique pipe

A technology of process pipe string and screw pump, which is applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problem of high power requirements of oil pumps, and achieve the effect of reducing power requirements and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

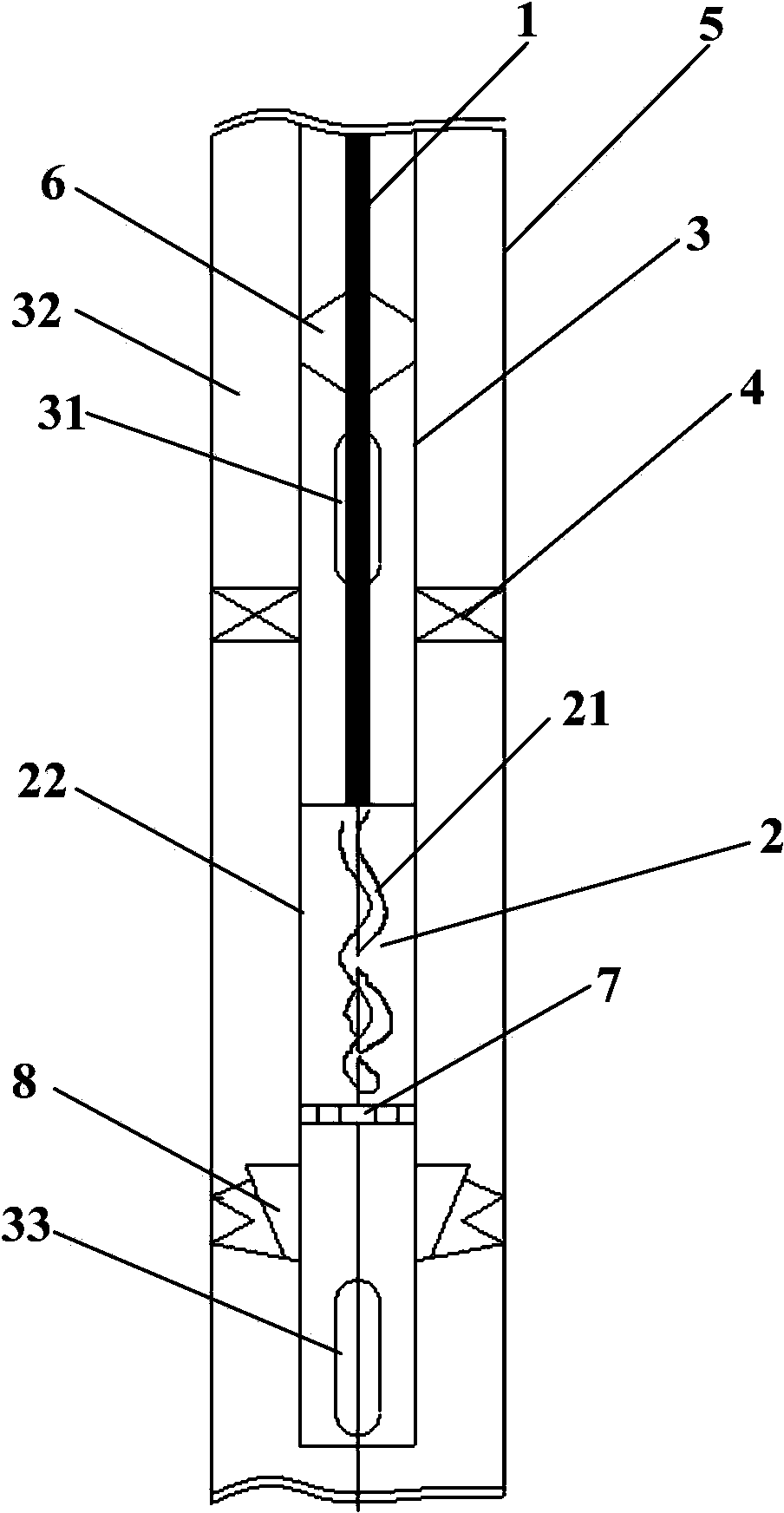

[0016] like figure 1 As shown, the embodiment of the present invention discloses a screw pump oil recovery process string, including: comprising: a sucker rod 1 and a screw pump rotor 21 sequentially connected from the ground; The oil pipe 3 extending downward; and the packer 4, the screw pump stator 22 and the anchor 8 connected to the oil pipe 3; wherein, the screw pump rotor 21 and the screw pump stator 22 form the screw pump 2; the oil pipe 3 is provided with The oil pipe 3 is connected with the diversion channel 31 on the outside of the oil pipe 3 , and the diversion channel 31 is located on the upper part of the packer 4 and the screw pump 2 .

[0017] In the embodiment of the present invention, such as figure 1 As shown, the screw pump oil recovery process string of the present invention also includes a casing 5 sleeved outside the oil pipe 3, and an oil jacket annulus 32 is formed between the casing 5 and the oil pipe 3, through which the packer 4 and the screw pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com