A Deformation Measurement Method of Large Structures Based on Fiber Bragg Grating Sensing Network

A fiber grating and sensor network technology, applied in measurement devices, optical devices, special data processing applications, etc., can solve the problems of sudden failure of the whole or local structure, difficulty in judging the degree of structural damage, and complex failure mechanism of the structure, etc. The effect of light weight, small size and concise curve fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

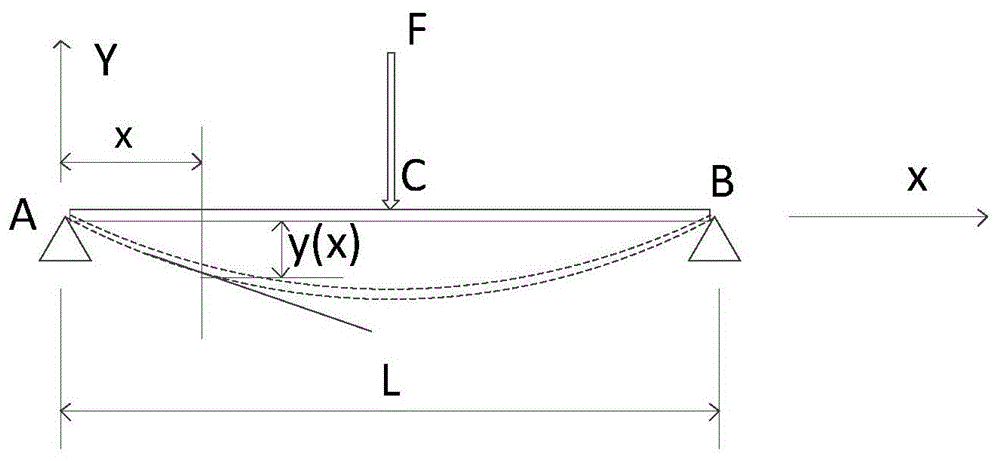

[0018] The principle of structural deformation measurement, when an unknown force F acts on a point C on a simply supported beam AB, the deformation of the beam is as follows: figure 1 Shown:

[0019] The bending deformation of the simply supported beam is shown, the axis of the beam changes from the original straight line to the curve, and the bent axis is called the deflection axis. The line displacement of a point whose coordinate is x on the beam axis is deformed in the direction perpendicular to the beam axis can be expressed as y(x), which is called the deflection of the point. For the beam st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com