Device for determination of foaming performance of foaming agent in CO2 and determination method thereof

A foaming performance and foaming agent technology, which is applied in the field of devices for measuring the foaming performance of foaming agents in CO2, can solve problems such as the inability to measure the foaming performance of foaming agents, and achieve rapid measurement methods, accurate results, and high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 whipping agent is 2000mg / L petroleum sulfonate aqueous solution

[0044] Prepare 1000mL of 2000mg / L petroleum sulfonate aqueous solution as the test solution (i.e. the foaming agent to be tested for the test), and carry out the following steps:

[0045] 1) connecting device;

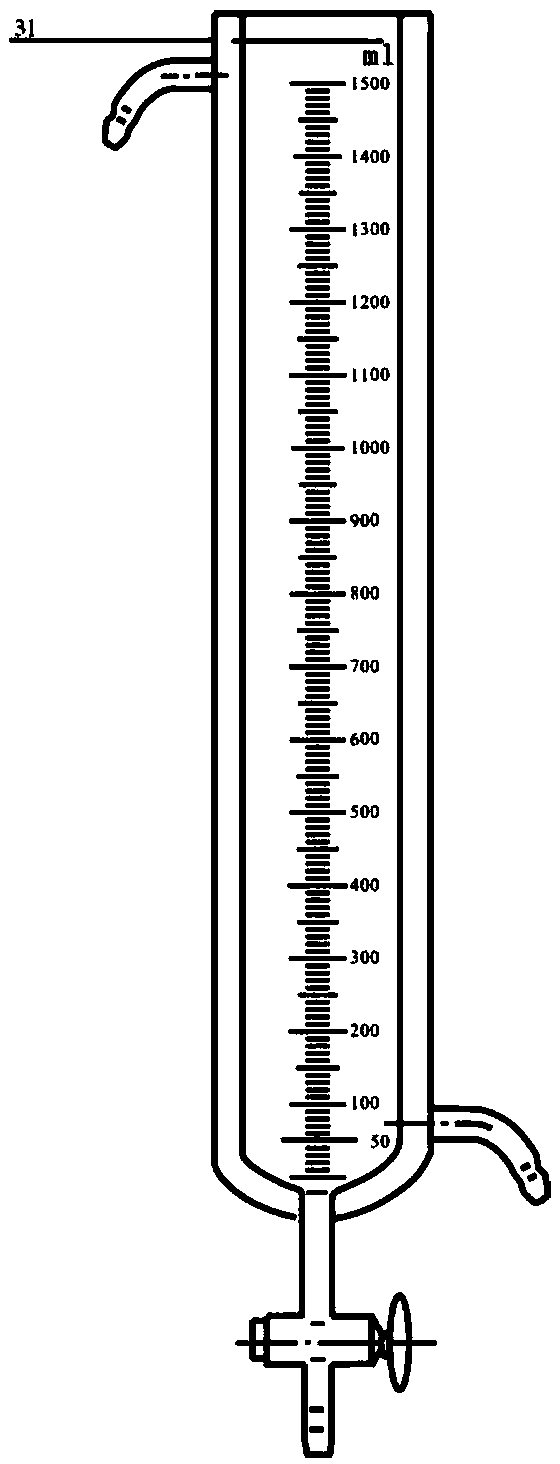

[0046] Use rubber water pipes to connect the outlet pipe and return pipe of the constant temperature water bath to the water inlet pipe and outlet pipe of the jacket measuring cylinder 3 respectively, and adjust the temperature of the constant temperature water bath to 50°C; In an isothermal water bath, make the temperature reach the water bath temperature, and set aside;

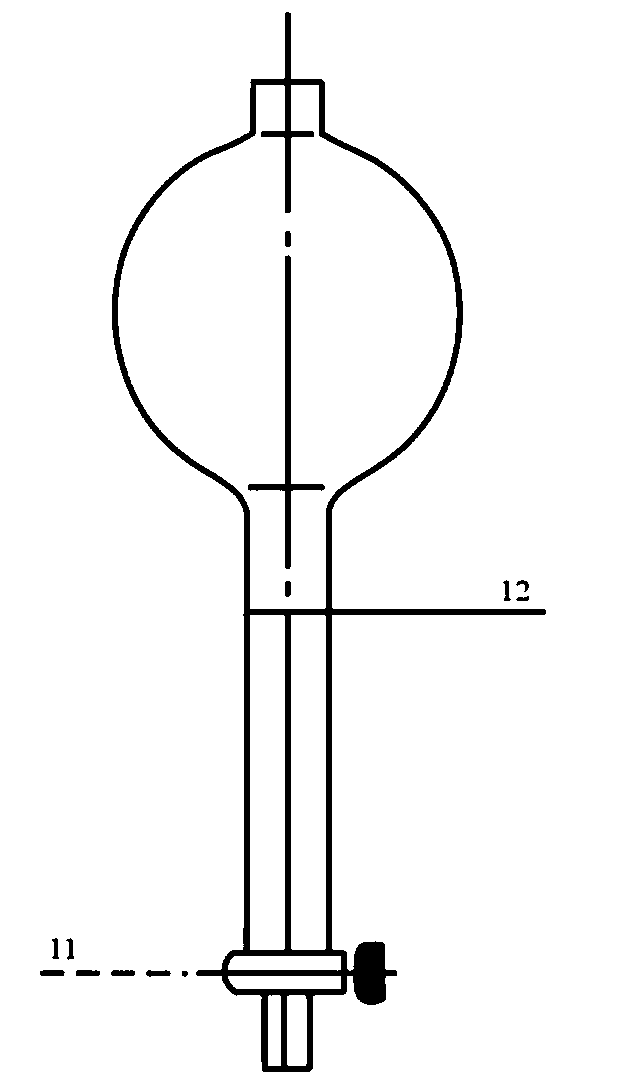

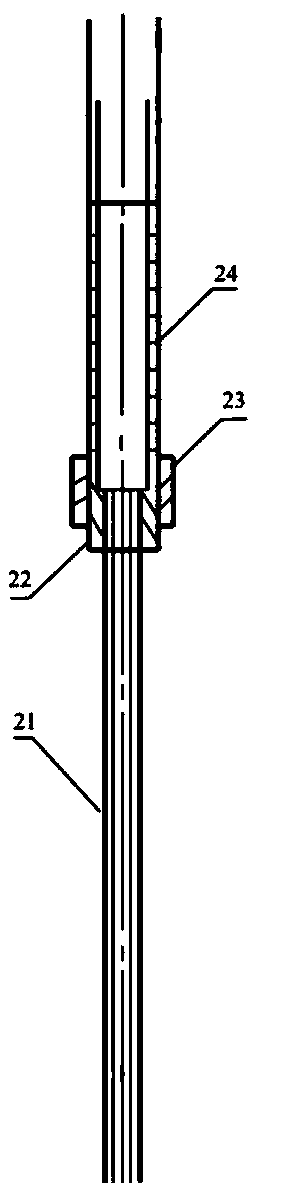

[0047] Install the metering tube combination structure 2 on the lower end of the separating funnel 1, and keep the metering tube combination structure 2 and the separating funnel 1 perpendicular to the horizontal plane;

[0048] Put the sealing rubber plug 4 on the mouth of the jacket measuring cylinder 3, insert...

Embodiment 2

[0056] Embodiment 2 whipping agent is 3000mg / L petroleum sulfonate aqueous solution

[0057] Prepare 1000 mL of 3000 mg / L petroleum sulfonate aqueous solution as a test solution, and repeat steps 1) to 3) of Example 1.

[0058] The foaming height measured in this embodiment is 340mL, and the half-life is 1120s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com