Automatic generating method of lift shaft drawing

An automatic generation, elevator shaft technology, applied in the field of drawing, can solve the problems of inspection failure, affecting the promotion of the drawing system, and consecutive failures of multiple inspections, and achieves the effect of reducing the use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

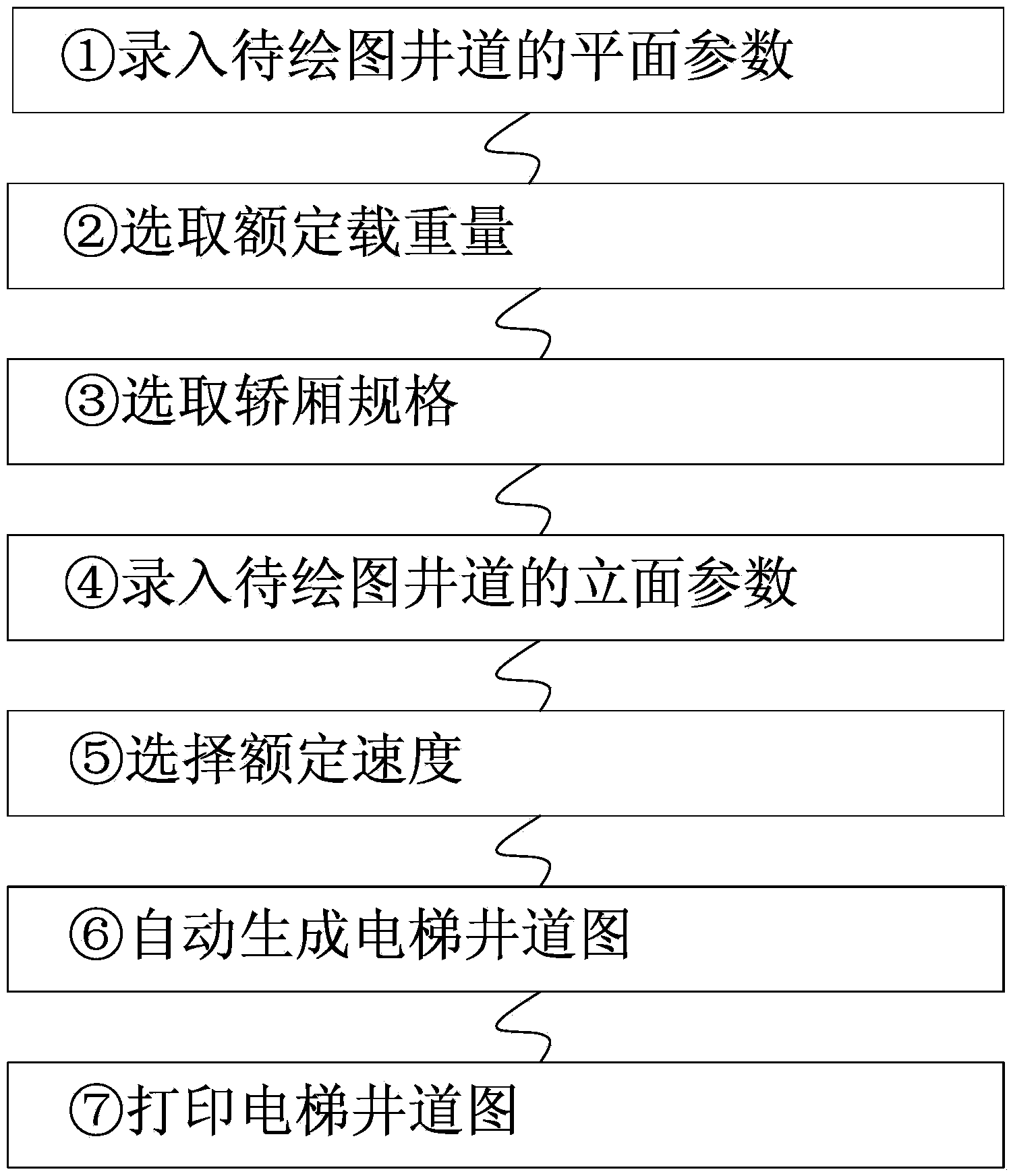

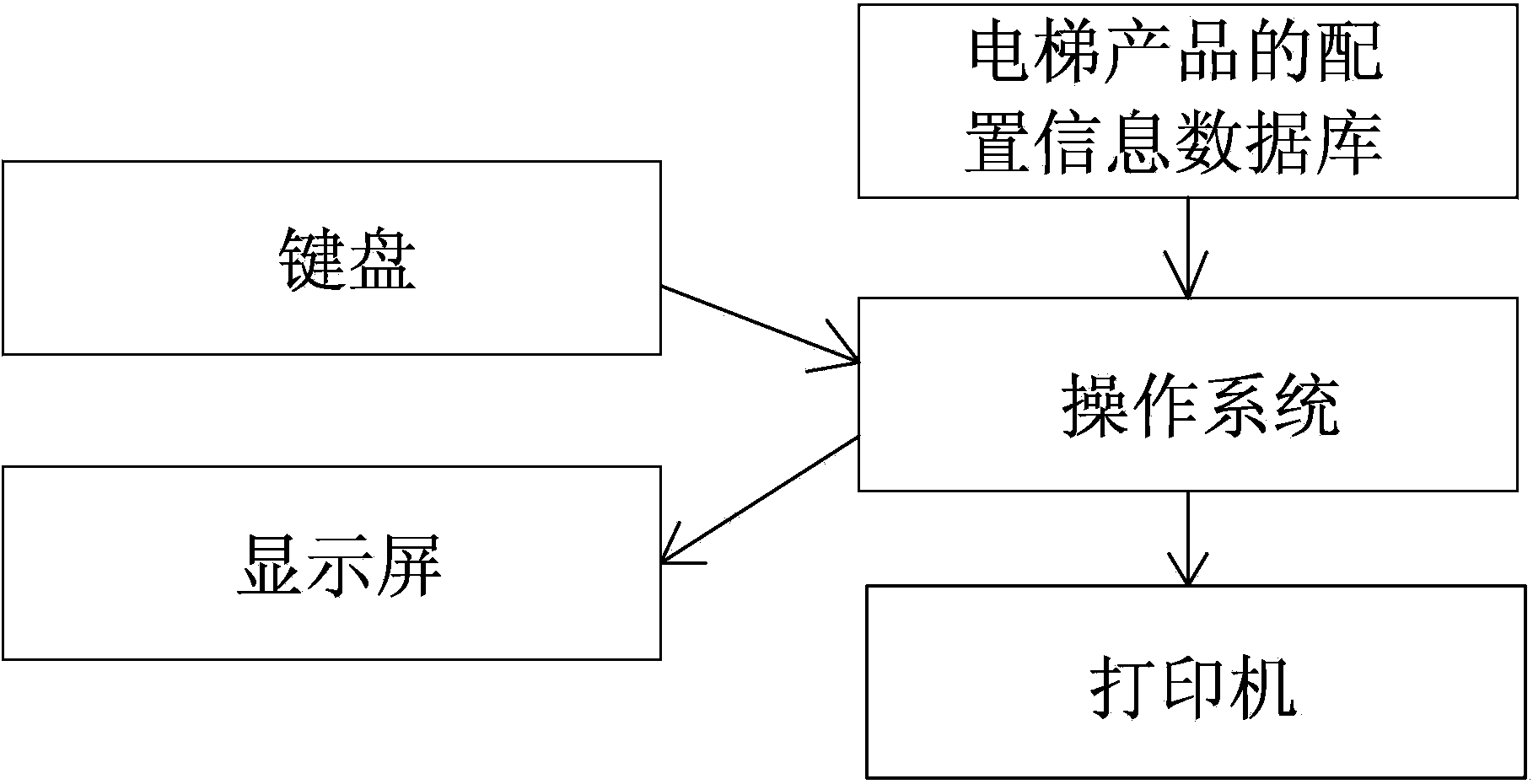

[0035] Such as figure 1Shown is an automatic generation method for an elevator shaft diagram, which specifically includes the following steps: ① Input the plane parameters of the hoistway to be drawn through the human-computer interaction interface on the display screen through the keyboard, and the plane parameters of the hoistway to be drawn are determined by the width of the hoistway to be drawn and Depth composition; ②Choose the rated load capacity; Among them, the operating system calculates the maximum car area under the specification of the well according to the input plane parameters of the hoistway to be drawn, combined with the guide rail bracket and the limit range of the distance between the guide rail bracket and the car, and uses According to the corresponding relationship between the car area and the load capacity in GB7588-2003 "Elevator Manufacture and Installation Safety Code", this area is used to deduce the limit load capacity of the car. When the user clic...

Embodiment 2

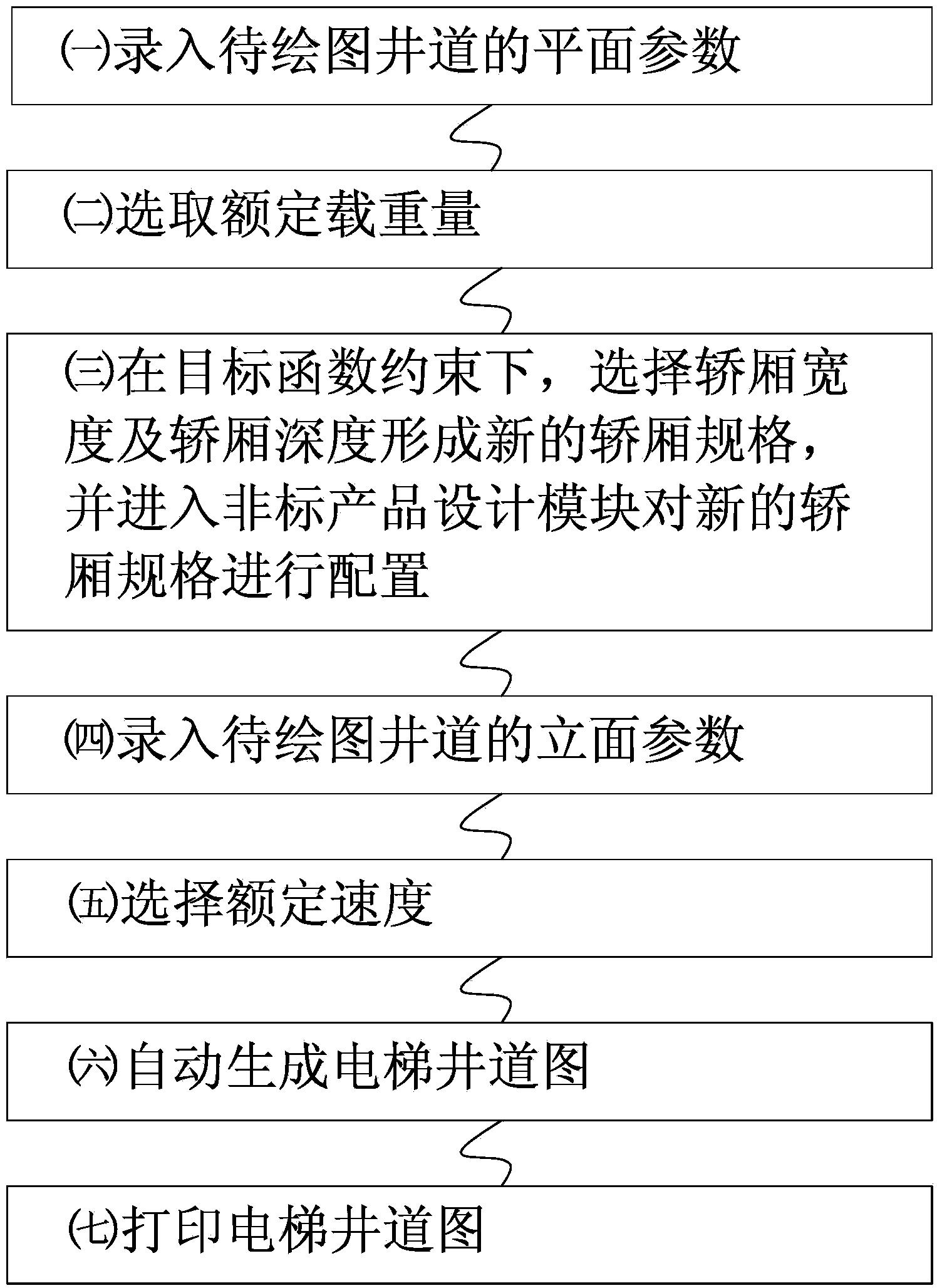

[0041] The automatic generation method of a kind of elevator hoistway diagram of the present embodiment is different from embodiment 1, as figure 2 As shown, it specifically comprises the following steps: (1) enter the plane parameters of the well to be drawn through the man-machine interface of the keyboard on the display screen, and the plane parameters of the well to be drawn are composed of the width and depth of the well to be drawn; (2) input according to step (1) The plane parameters of the hoistway to be drawn are selected as the limit load capacity, and the limit load capacity is calculated by the operating system according to the plane parameters of the hoistway to be drawn to be entered, combined with the constraints of the guide rail bracket and the limit range of the distance between the guide rail bracket and the car. The maximum car area, and this area is deduced from the corresponding relationship between the car area and the load in GB7588-2003 "Safety Code fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com