Die-casting pouring method for left engine mounting bracket and mold thereof

A technology for a left mount and an engine is applied in the field of a die-casting and pouring method for a left mount bracket of an engine and its mold field, which can solve the problems of slow production speed, heavy product quality, and increased vehicle weight, so as to reduce production costs and achieve fast production speed. , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

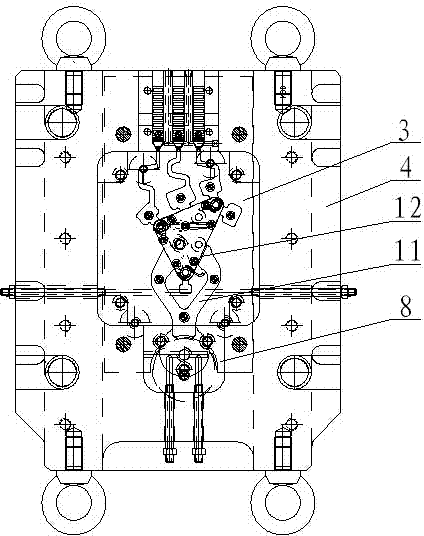

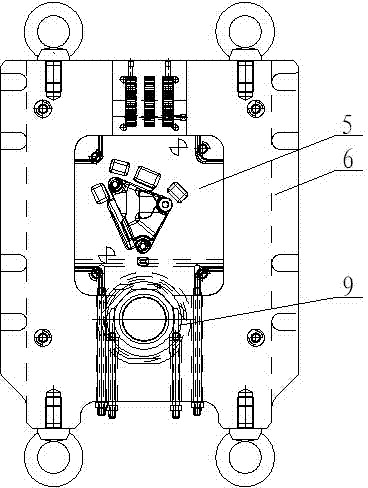

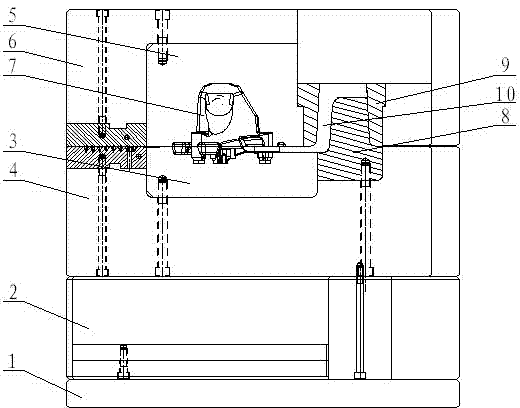

Image

Examples

Embodiment 1

[0023] Embodiment 1: A die-casting and pouring method for the left suspension bracket of an engine, the die-casting and pouring method has the following steps:

[0024] 1) Install the mold on the die casting machine;

[0025] 2) Pour aluminum water into the melting cup material tube in the mold;

[0026] 3) Press the aluminum water in the melting cup tube through the sprue to the gate in the mold at a low speed by the hammer head of the die-casting machine;

[0027] 4) Press the hammer head forward at high speed, and press the aluminum water in the melting cup material tube into the mold cavity and slag bag;

[0028] 5) pressurize through the hammer to solidify the product in the cavity;

[0029] 6) Open the die-casting machine to demould the product;

[0030] 7) Remove the slag bag and sprue on the product.

[0031] Further, the pressure of the die-casting machine at low speed and high speed is 14MPa, the speed is 0.2m / s and 3m / s respectively, and the pressure is 28-33MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com