Clamping and rotating mechanism of steel tube inner wall polishing device

A technology of rotating mechanism and internal polishing, applied in surface-polished machine tools, grinding/polishing equipment, grinding machine parts, etc. Stable, reasonable structure setting, good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

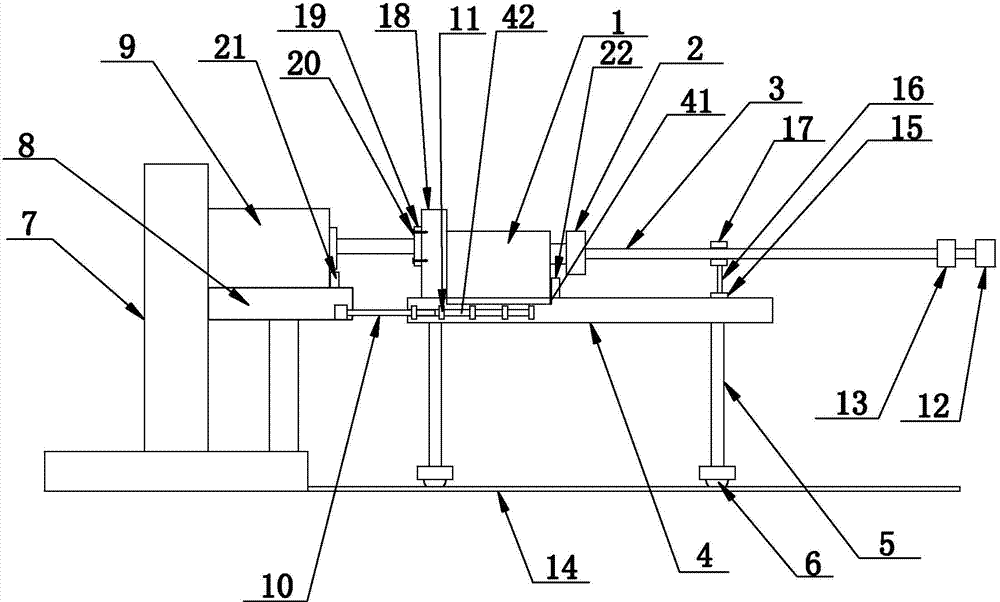

[0014] see figure 1 , a clamping and rotating mechanism of a steel pipe internal polishing device disclosed in the present invention includes a motor 1 and a three-jaw chuck 2 fixedly installed on the motor spindle, and a grinding rod 3 is inserted into the three-jaw chuck 2, so that The lower end of the motor 1 is provided with a motor base 4, the bottom of the motor base 4 is fixedly provided with four legs 5, and the bottom of each leg 5 is fixedly provided with a roller 6, and the upper end of the motor base 4 is provided with a motor mounting groove 41. The motor 1 is fixedly installed in the motor installation groove 41, the left end of the motor base 4 is provided with a cylinder base 7, and the right end surface of the cylinder base 7 is integrally provided with a support platform 8, and the cylinder 9 is fixedly installed on the support platform 8, The piston rod head of the cylinder 9 is detachably connected to the left end surface of the motor seat 4, and a transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com