Plastic product and molding method thereof

A molding method, injection molding technology, applied in the direction of coating, etc., can solve the problems of difficult to achieve seamless effect, pollute the environment, high defect rate, etc., and achieve the effect of high yield rate, simple manufacturing process, and beautiful seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

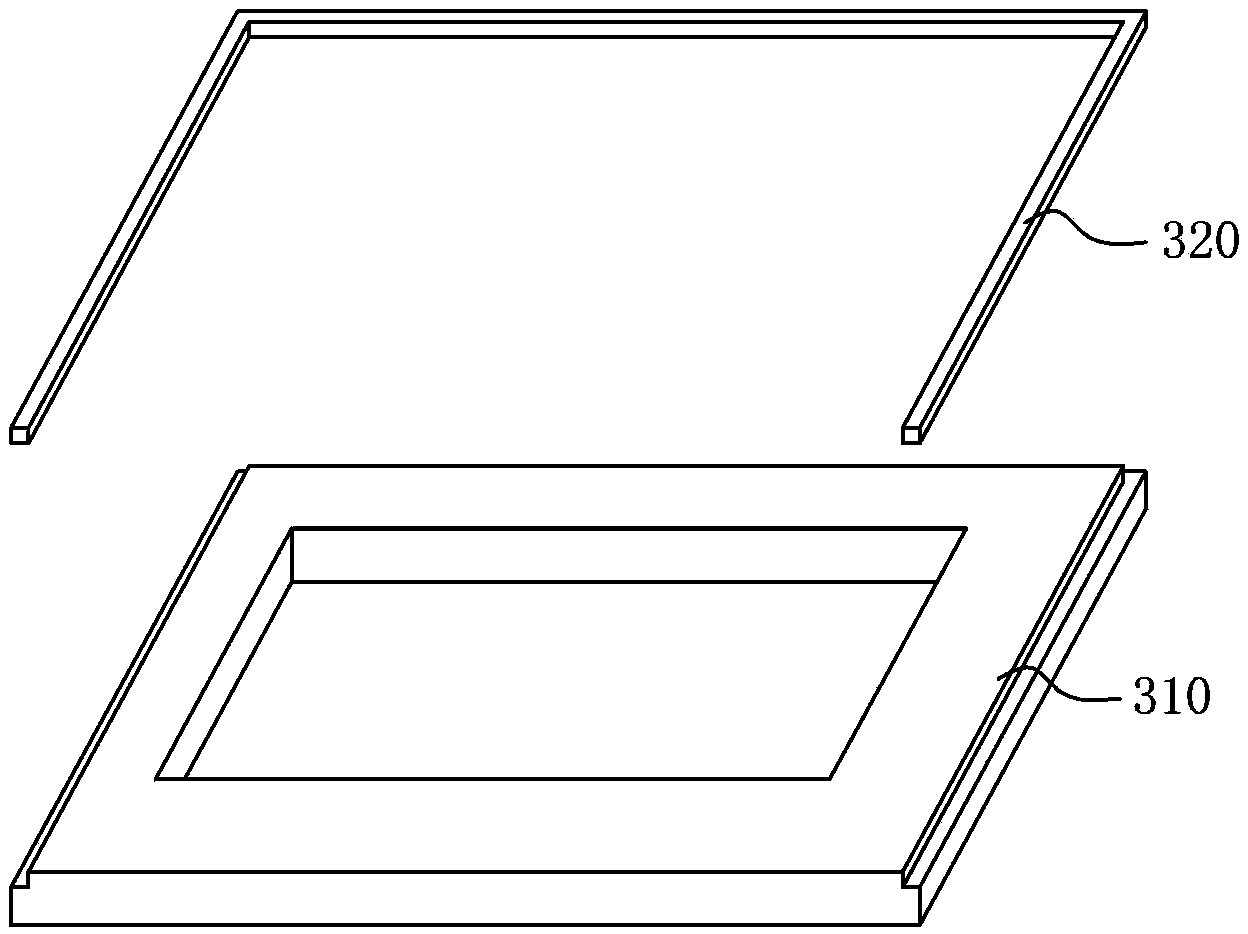

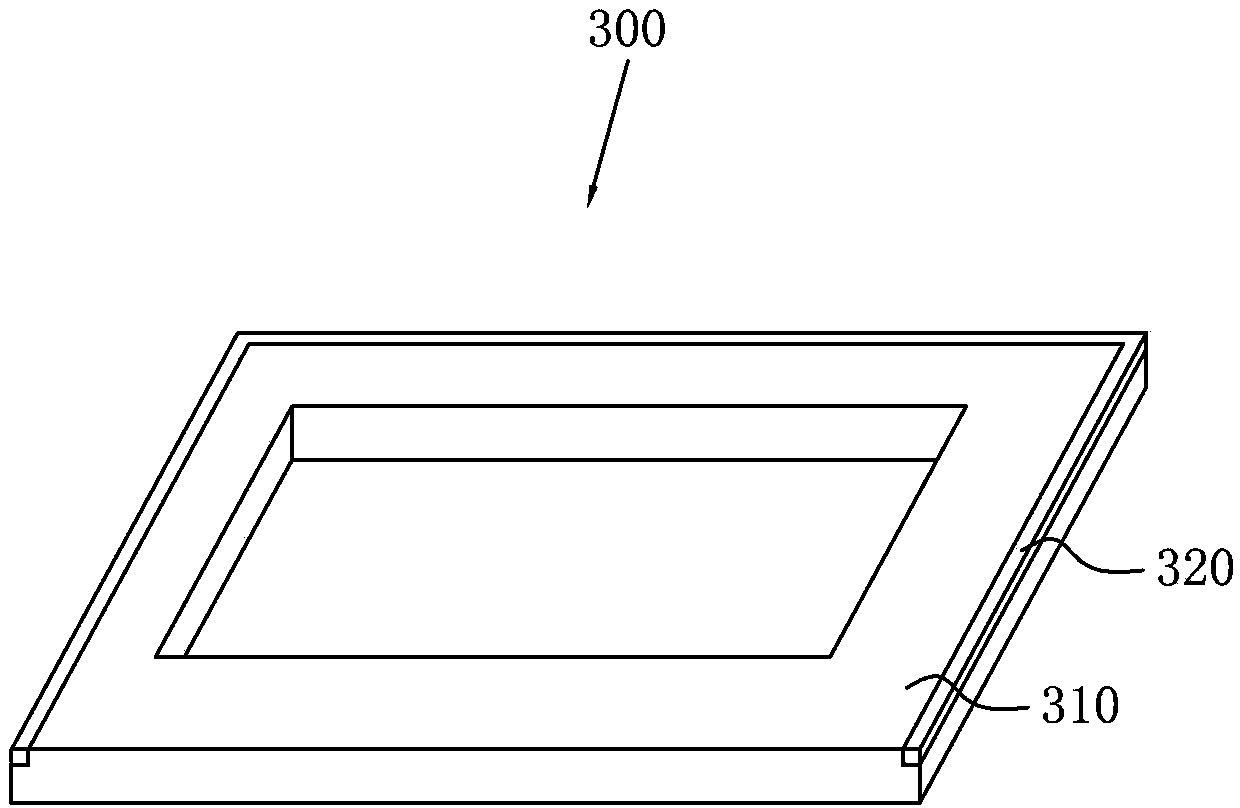

[0026] In Example 1, see Figure 1 to Figure 3 As shown, the first plastic product 310 and the second plastic product 320 are formed by double injection molding. Therefore, the molding machine is a double-shot molding machine, and the double-shot molding machine cooperates with two sets of injection molds to form the plastic product 300 sequentially. The two sets of injection molds are respectively the first set of injection molds and the second set of injection molds. The structure of the male mold part of the first set of injection mold and the second set of injection mold is exactly the same, but the structure of the female mold part is different.

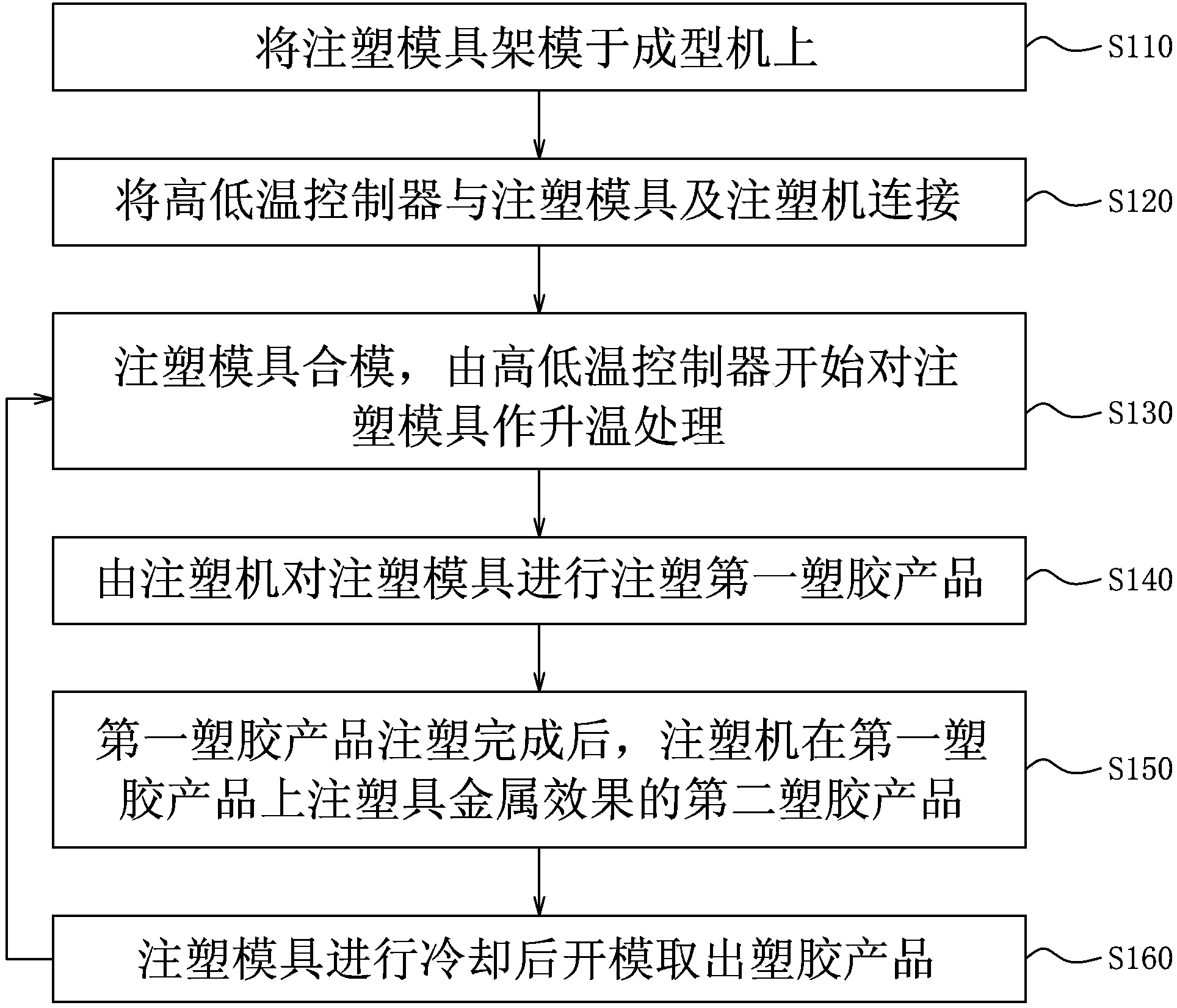

[0027] In embodiment 1, the molding method of the plastic product of the present invention comprises the following steps:

[0028] Step S110: placing two sets of injection molds on the two-shot molding machine;

[0029] Step S120: connecting the high and low temperature controllers to the two sets of injection molds and the in...

Embodiment 2

[0035] In Example 2, see figure 2 and image 3 As shown, the first plastic product 310 and the second plastic product 320 are molded by insert molding. Therefore, the molding machine is two single-shot molding machines, and the two single-shot molding machines cooperate with two A plastic product 300 is formed by a set of injection molds, the two sets of injection molds are respectively the first set of injection molds and the second set of injection molds.

[0036] In embodiment 2, the molding method of the plastic product of the present invention comprises the following steps:

[0037] Step S210: Mounting the two sets of injection molds on two single-shot molding machines respectively;

[0038] Step S220: connecting the high and low temperature controllers to the two sets of injection molds and the injection molding machine, wherein the injection molding machine is used to inject hot melt plastic into the two sets of injection molds for injection molding;

[0039] Step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com