Special spoon-shaped wing section with ultra-low Reynolds number, high lift-drag ratio and low speed

A technology with high lift-drag and airfoil, which is applied in the field of special spoon-shaped airfoil with extremely low Reynolds number, high lift-drag ratio and low speed, which can solve the problem of deterioration of airfoil lift-drag performance, instability of laminar boundary layer, and no new airfoil proposed and other problems, to achieve excellent aerodynamic performance, small laminar flow separation bubble, and high lift-to-drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

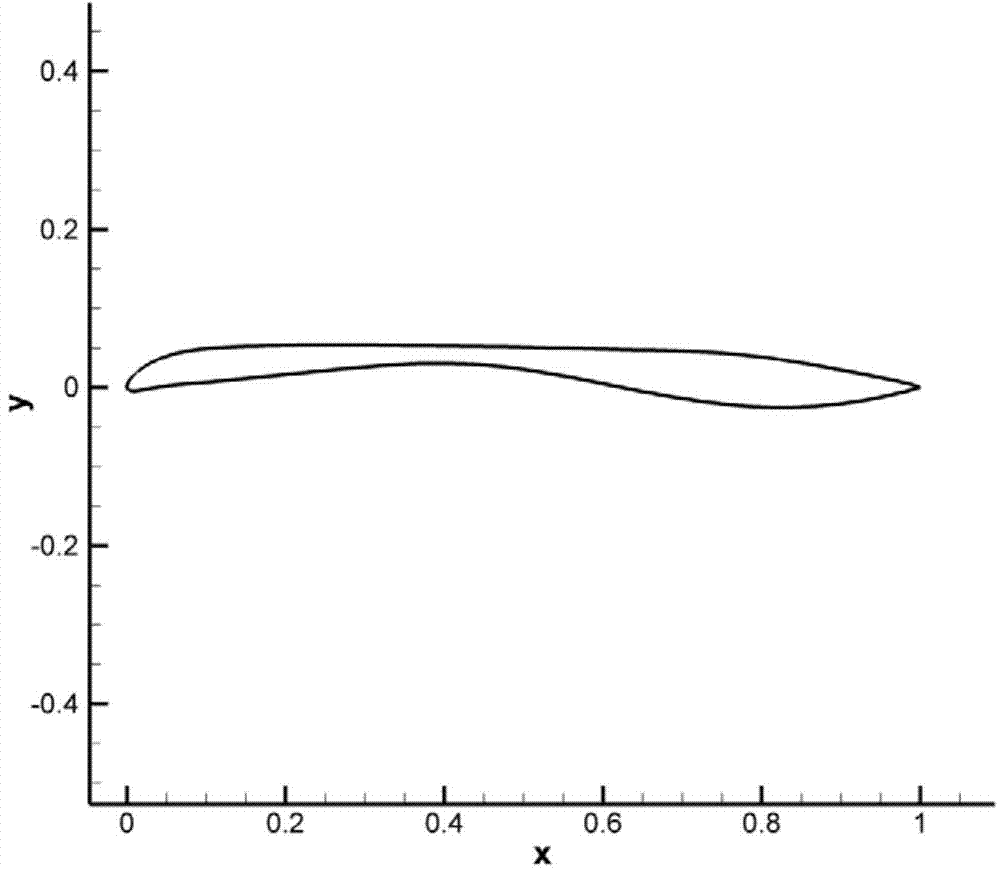

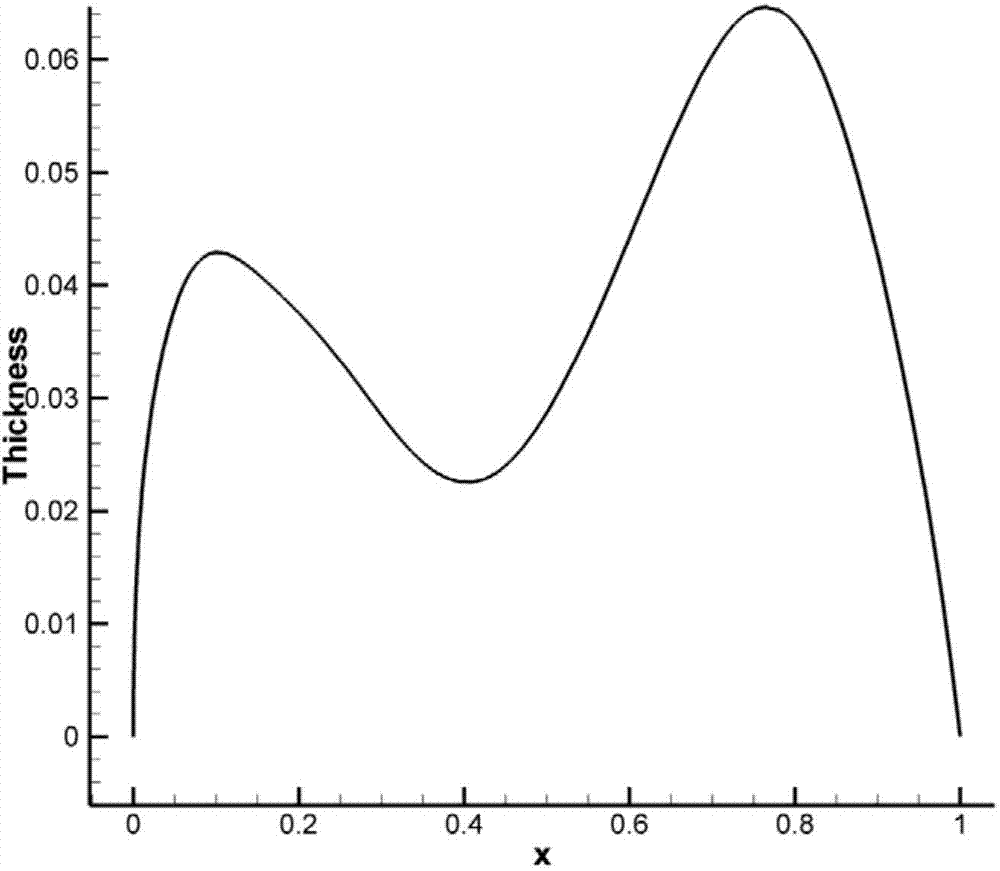

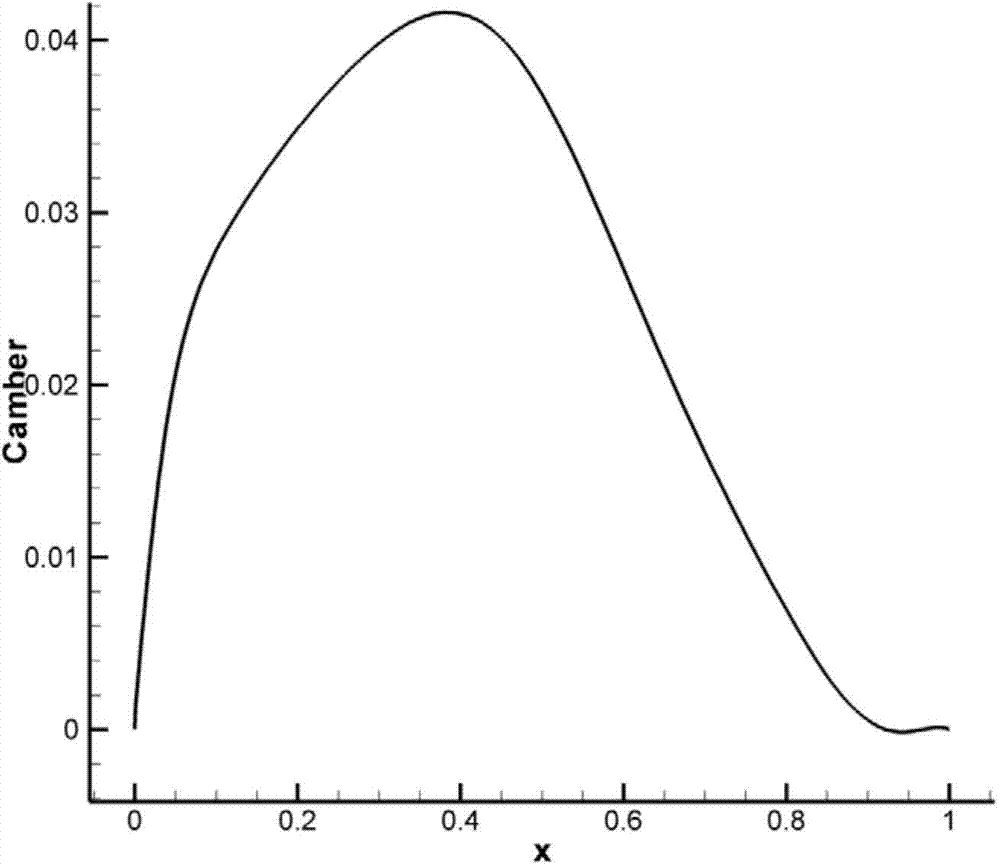

[0038] The present invention has designed a kind of suitable ~ 10 4 Very low Reynolds number high lift airfoil for low speed at Reynolds number. The prominent features of this airfoil are: the thickness of the airfoil before 60% of the chord length is small, and the thickness of the airfoil after 60% of the chord length is large, forming a "spoon-shaped" geometric feature, and the maximum relative thickness of the airfoil before 60% of the chord length It is about 66% of the maximum relative thickness of the airfoil after 60% of the chord length. The maximum relative thickness of the airfoil is located at about 77% of the chord length, and there is a thinner area of the airfoil at about 40% of the chord length, and the minimum relative thickness of the airfoil here is about 35% of the maximum relative thickness of the airfoil. The thickness of the front part of the airfoil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com