Gravitational acceleration sensor based road surface flatness detection method

A technology of gravitational acceleration and detection method, applied in the field of detection, can solve the problems of cumbersome detection process and high price, and achieve the effects of solving the cumbersome detection process, eliminating influence and solving expensive price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

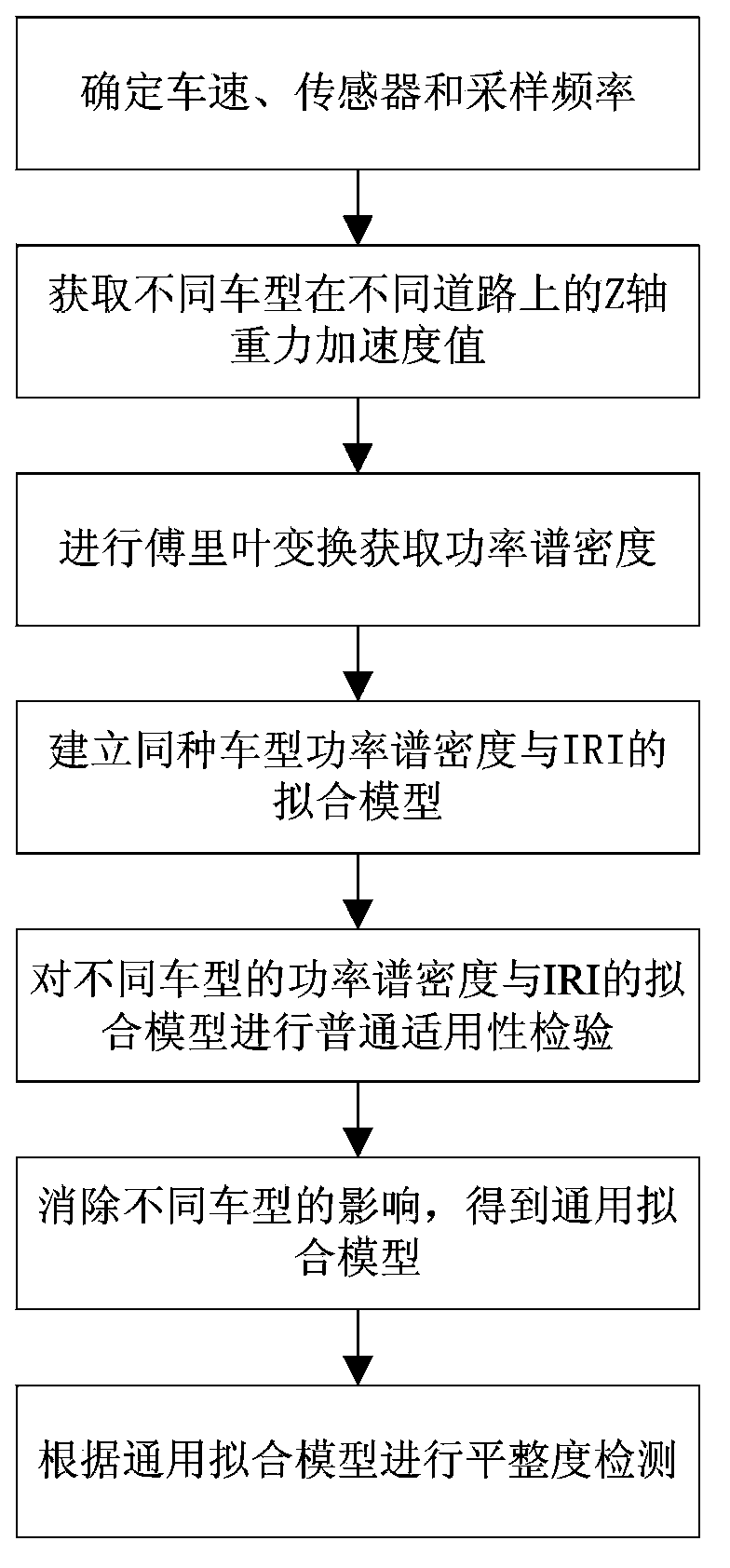

[0024] Such as figure 1 As shown, a road surface smoothness detection method based on a gravity acceleration sensor includes the following steps:

[0025] (1) Determine the vehicle speed to be detected, and select the gravity acceleration sensor and its sampling frequency;

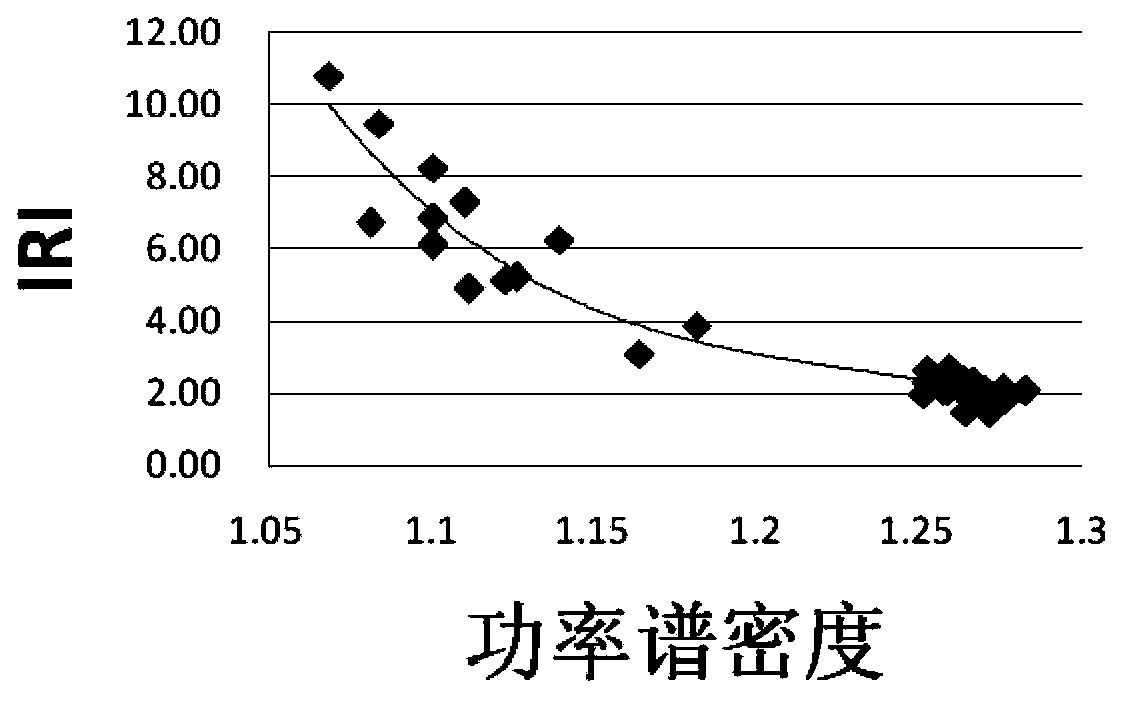

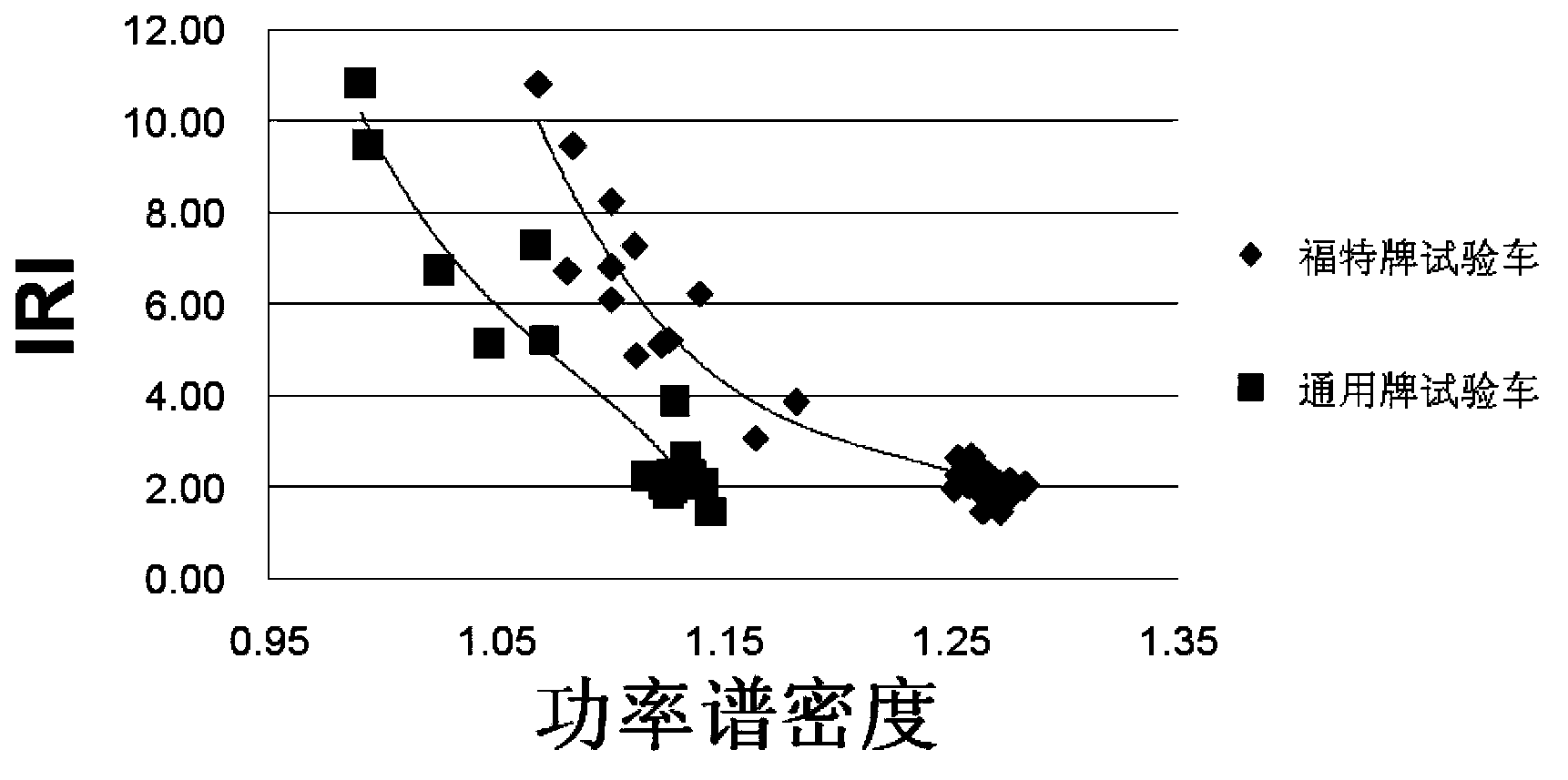

[0026] (2) Test vehicles of different models are used to drive on roads with different road surface smoothness, and the gravity acceleration value of the gravity acceleration sensor is obtained in the form process. In the process of driving, the unevenness of the road will arouse the vibration of the car, and the vibration of the car will inevitably produce vertical acceleration of the up and down bumps, that is, the gravity acceleration of the Z axis, and the magnitude of the Z axis gravity acceleration reflects the bump of the car The size of the road indirectly reflects the unevenness of the road. The selection of the gravity acceleration sensor and the determination of the required sampling frequency are v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com