An easy-to-disassemble steel structure connection device

A technology for connecting device and steel structure, applied in the direction of building structure, construction, etc., can solve the problems of difficulty in dismantling, restrictions on the promotion of steel structure houses, time-consuming and labor-intensive welding process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

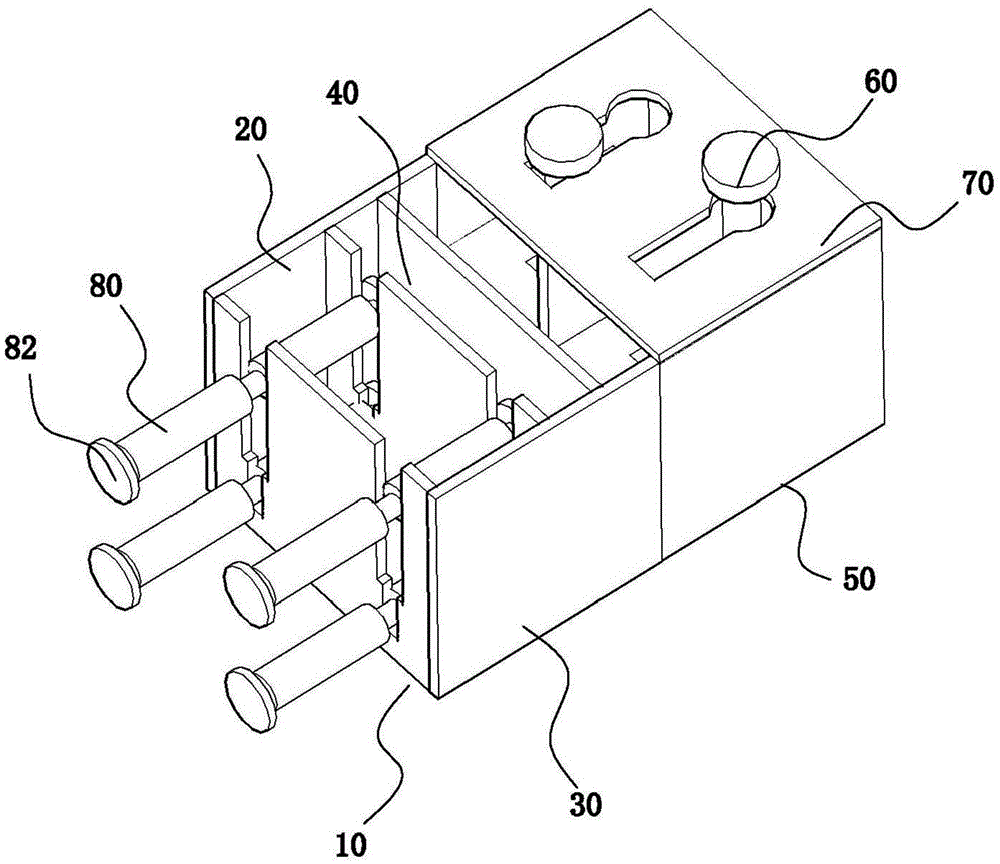

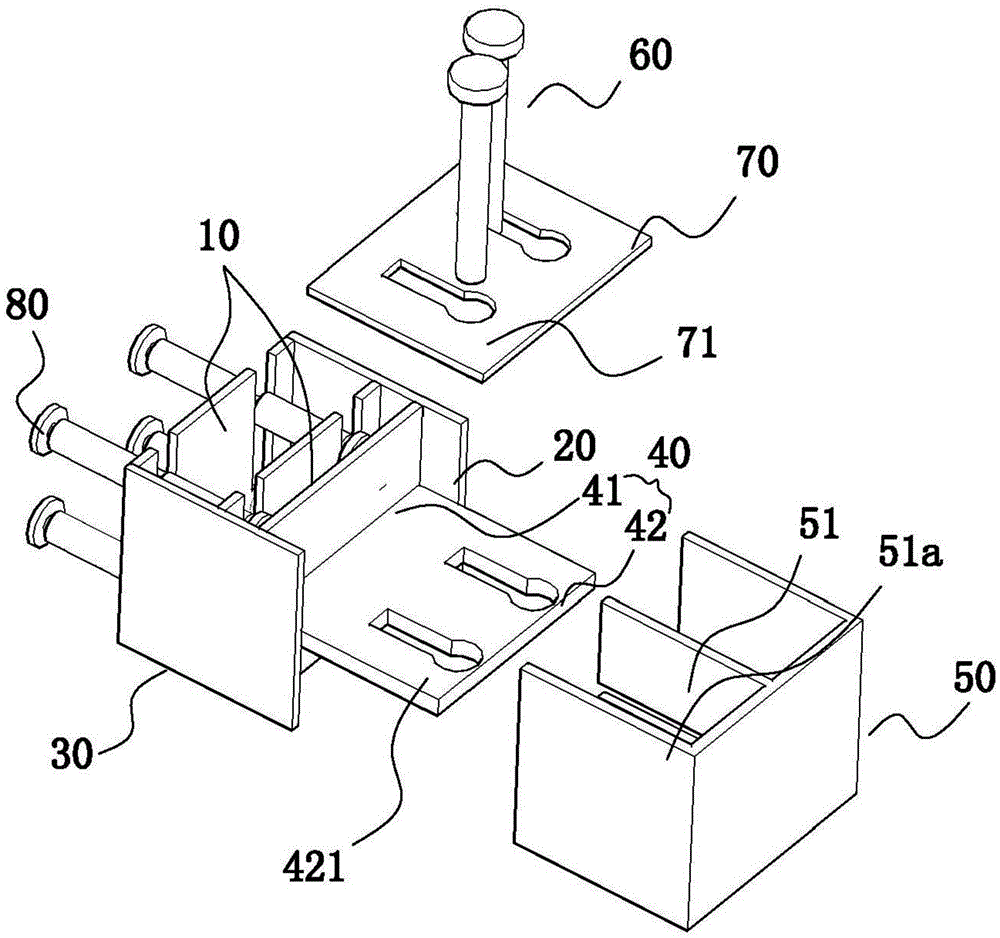

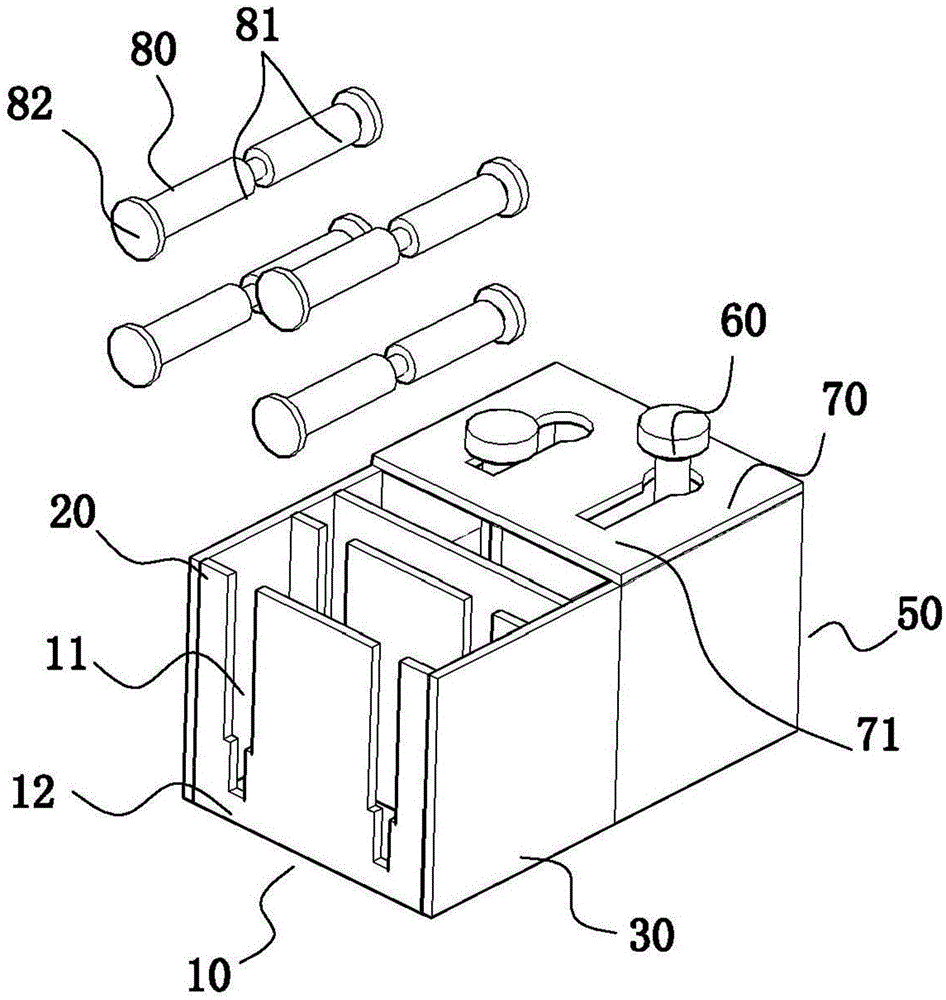

[0022] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

[0023] like Figure 1-4 As shown, a steel structure connection device that is easy to disassemble includes two or more metal plug-in boards 10 with the same structure, a left side panel 20 for welding the metal plug-in boards 10 arranged at intervals and The right side panel 30 and the "T" shaped connecting plate 40, the bottom plate 41 of the "T" shaped connecting plate 40 is connected and fixed between the left side panel 20 and the right side panel 30, the middle plate 42 of the "T" shaped connecting plate 40 The protruding part of the left side panel 20 and the right side panel 30 is vertically inserted into the middle plate 51 of the "mountain" shaped frame 50 through a slot, and the middle plate 42 of the "T" shaped connecting plate 40 is provided with a Two horizontal slots one 421 for the sliding connection of the bolt 60 are welded wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com