Three-dimensional simulation measuring method and device for remaining oil saturation of oil reservoir

A technology of measuring device and measuring method, which is applied in the indoor test field of petroleum thermal recovery process, and achieves the effect of bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

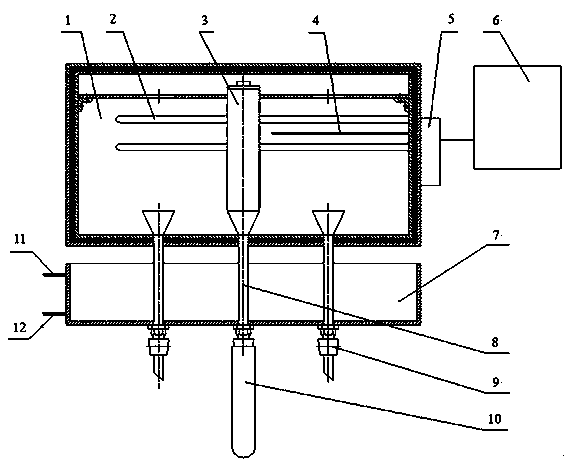

Embodiment 1

[0038] 1. Oil sand sampling: According to actual needs, the three-dimensional simulated oil reservoir after experimental displacement is stratified in the vertical direction (the number of layers is greater than or equal to three layers), and the grid is divided from the uppermost layer to evenly divide the layer into 6× 6 or 7×7 areas, or divide more different areas according to actual needs. For convenience, we call these different areas sampling points. Take out an appropriate amount of oil sand from each sampling point, and pack it with a label with good sealing performance. Seal in the bag. Then mark the bag with the coordinate method. After taking an appropriate amount of oil samples from each sampling point, remove the excess oil sands in this layer, and sample the next layer of oil sands according to the above method. In order to avoid the error caused by the evaporation of the oil sample for a long time, this step is required to be carried out as soon as possible afte...

Embodiment 2

[0055] Embodiment 2: Except that the following content is different from Embodiment 1, other content is the same as Embodiment 1, and will not be repeated:

[0056] (1) Take 30g of the oil sand in step 1, weigh the mass with an electronic balance and record it as m 1 Pack the gauze tightly, put the gauze covered with oil sand into the dry distillation barrel 3, cover it and seal it, and make a corresponding mark. Take another 9 oil samples and do the same operation.

[0057] ③ Dry distilled water: Set the initial temperature to 100℃ by the temperature controller 6. At this time, the heating furnace 2 is heated, the temperature in the constant temperature box 1 rises, and the temperature sensor 4 uploads the measured temperature in the constant temperature box 1 to the temperature controller 6 , But when the temperature reaches 100℃, it stops rising to maintain this temperature. When condensed water appears in the collecting pipe 10, start to record the volume of water, and record ...

Embodiment 3

[0059] Embodiment 3: Except that the following content is different from Embodiment 1, other content is the same as Embodiment 1, and will not be repeated here:

[0060] (1) Take 50g of oil sand in step 1, weigh its mass with an electronic balance and record it as m 1 Pack the gauze tightly, put the gauze covered with oil sand into the dry distillation barrel 3, cover it and seal it, and make a corresponding mark. Take another 9 oil samples and do the same operation.

[0061] ③ Dry distilled water: Set the initial temperature of 150℃ by the temperature controller 6. At this time, the heating furnace 2 is heated, the temperature in the thermostat 1 rises, and the temperature sensor 4 uploads the measured temperature in the thermostat 1 to the thermostat 6 , But when the temperature reaches 150℃, it stops rising to maintain this temperature. When condensed water appears in the collecting pipe 10, start to record the volume of water, and record it every 20 minutes. When three consecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com