Pressure reduction and vibration damping runner cone device

A technology of scupper cone and scupper hole, which is applied in the directions of hydropower generation, engine components, machines/engines, etc., can solve the problems of high thrust pad temperature, high pressure of the top cover, damage of the unit, etc., so as to improve the stress condition and reduce the Pressure pulsating, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

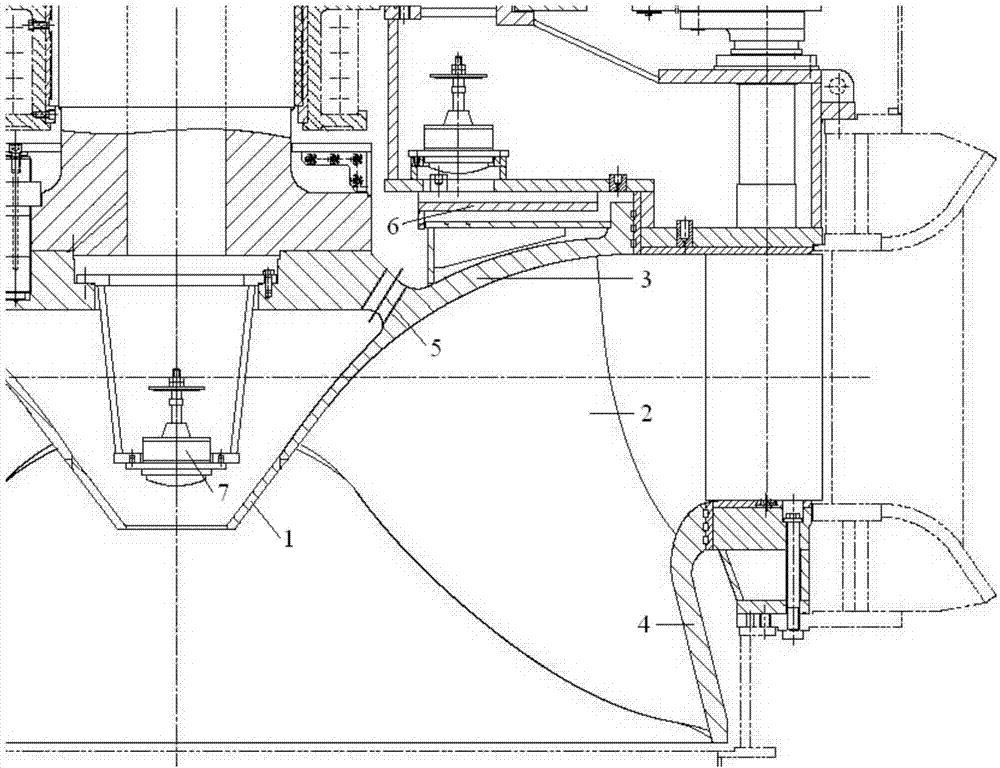

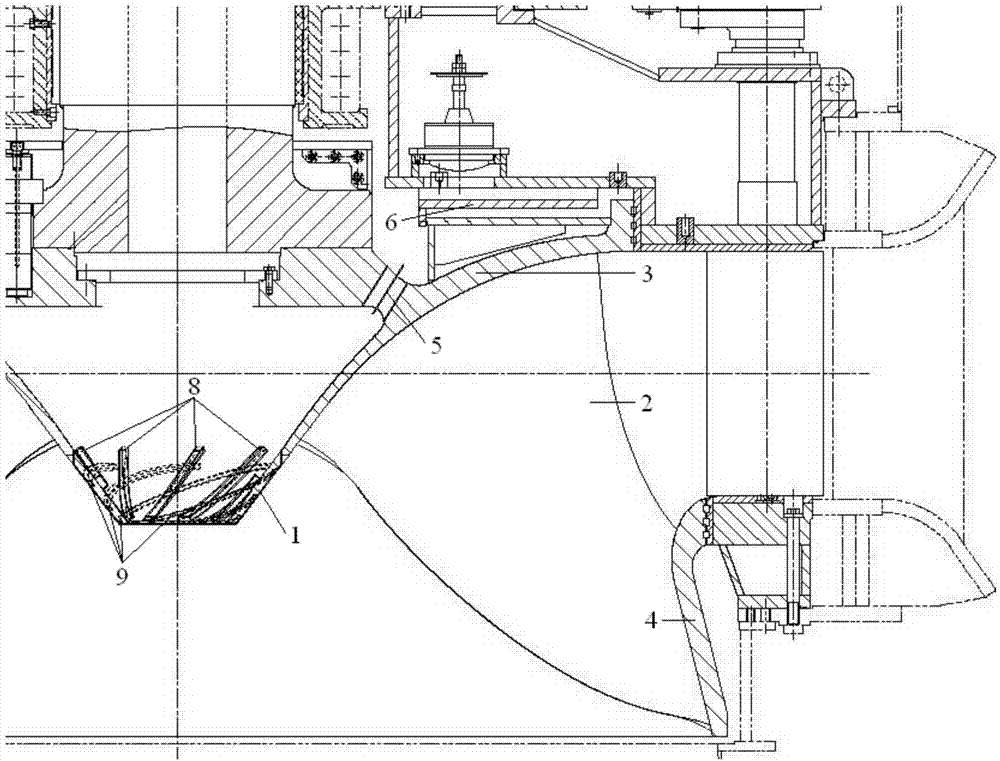

[0019] Such as figure 2 As shown, the decompression and damping water discharge cone device of the present invention includes a water discharge cone 1 connected to the upper crown 3 of the runner, the inside of the water discharge cone 1 is welded with uniformly distributed ribs 8, and the outside of the water discharge cone 1 There are evenly distributed spiral grooves 9 . The number of weep holes 5 is 14 evenly distributed, and the number of blades 2 is 13. The rotation direction of the unit is clockwise when viewed from the direction of the generator to the turbine.

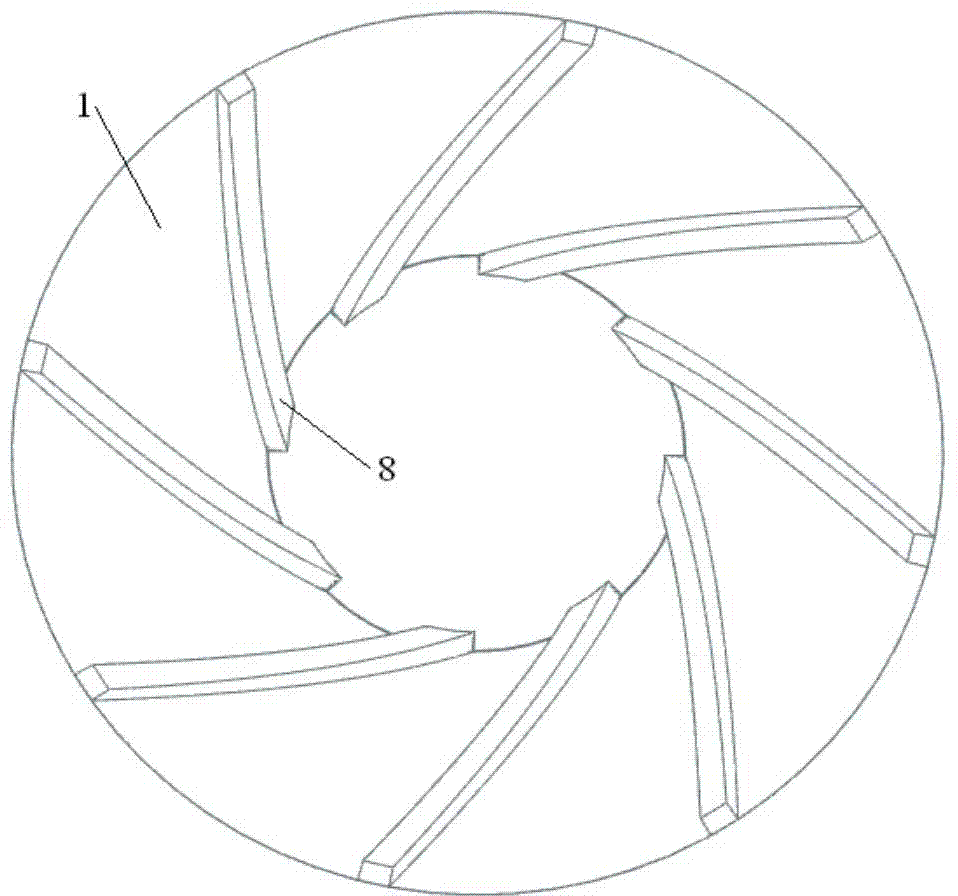

[0020] Such as image 3 As shown, the ribs 8 are inclined in the discharge cone 1, that is, they are inclined from the top of the discharge cone 1 to the bottom of the discharge cone 1 along the direction of rotation of the unit, and the inclination angle is 30° from the central axis of the runner. angle.

[0021] The ribs 8 are flush with the top and bottom of the drain cone 1, the width of the ribs 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com