Smooth high-speed centrifugal water injection pump

A high-speed, water-injection pump technology, applied in the field of centrifugal pumps, can solve the problems of sharp decline in corrosion resistance, high cost of replacing parts, and high cost of parts, so as to improve reliability and stability, reduce noise and vibration, and assemble Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

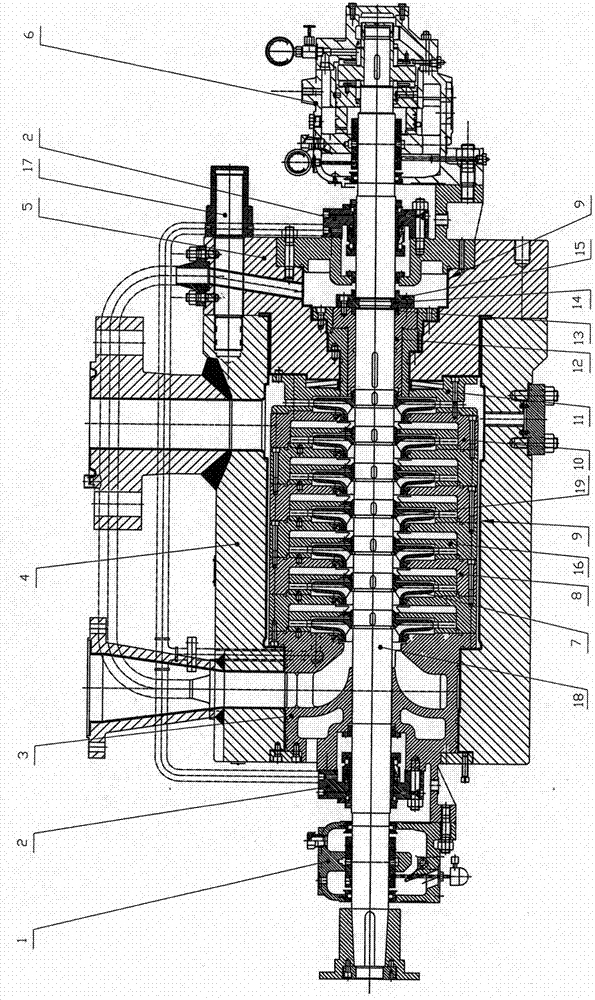

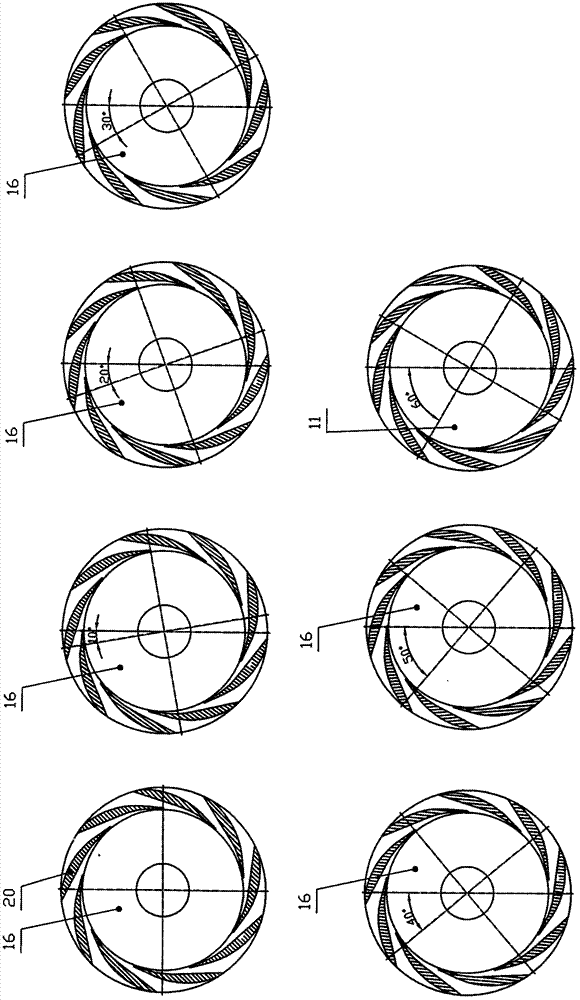

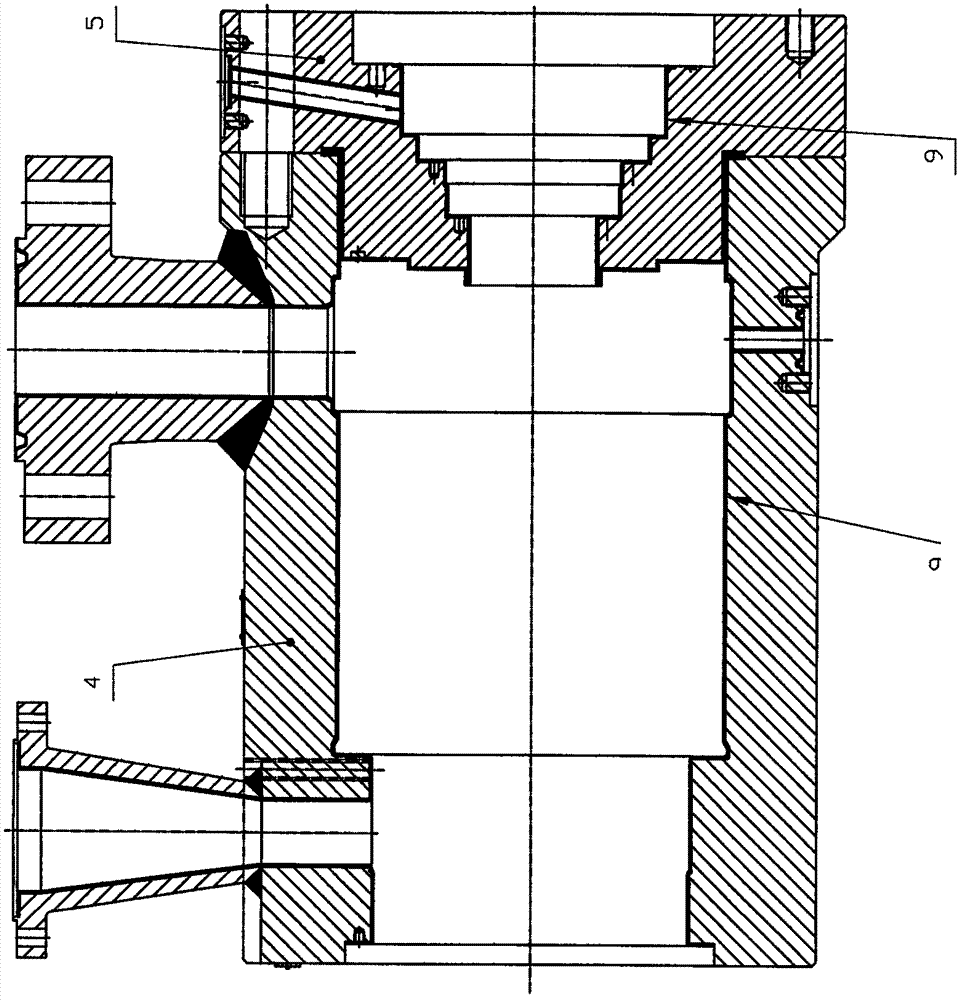

[0011] refer to Figure 1 to Figure 3 It can be seen that the smooth (small flow) high-speed centrifugal water injection pump of the present invention includes a pump cover 5, a housing assembly, a rotor assembly, a bearing assembly (including a left bearing assembly 1 and a right bearing assembly 6), and a mechanical seal assembly 2. The casing assembly includes a suction box body 3, a middle section 8, a final middle section 10, guide vanes 16 (several stages, except the last guide vanes) and a final guide vane 11 connected in sequence, the guide vanes 16, the final guide vanes The angle of the hydraulic inlet and outlet direction of the blade 11 is arranged in increments of 10° to 15° (set at a fixed numerical angle within this range) from the guide vane of the first stage to each stage of the guide vane of the last stage (such as figure 2 As shown, when the number of blades 20 on the guide vane 16 is nine pieces, it is one circle when it is rotated to a range of 30° in in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com