Detection method for pore size and pore size distribution of diaphragm

A technology of aperture size and detection method, applied in the direction of measuring device, color/spectral characteristic measurement, instrument, etc., can solve local, dangerous, inconvenient problems, etc., and achieve consistent detection results, consistent usage, and short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

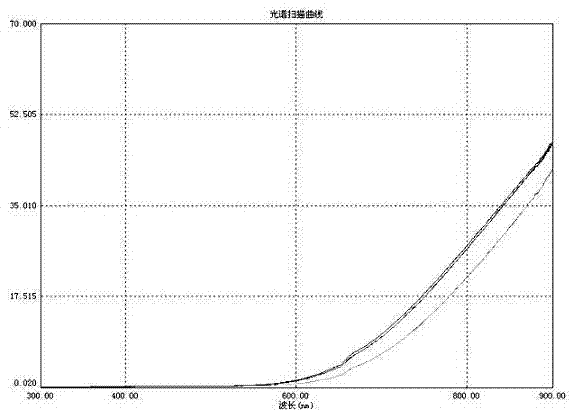

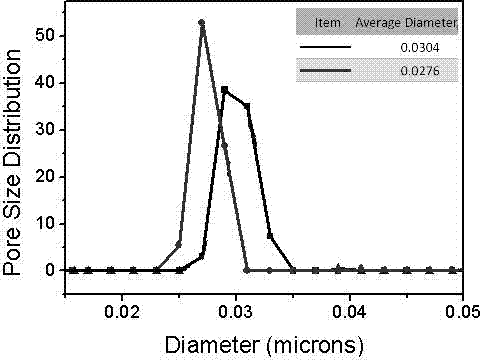

[0012] A method for detecting the pore size and distribution of a diaphragm according to the present invention is carried out according to the following steps. The diaphragm is scanned with a visible spectrophotometer, set from 300nm to 900nm, and the visible spectrophotometer automatically starts from the small wavelength to the end of the maximum wavelength, scans and Generate a curve; it can be seen from the curve that when the light transmittance is around 47-49 at a wavelength of 900nm, it means that the average pore size of the diaphragm is 27nm and relatively uniform; if the light transmittance is 41-42, it means that the pore size of the diaphragm is greater than 30nm and Pore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com