Intelligent laser cleaning robot for track

A technology of laser cleaning and robotics, which is applied in the field of intelligent robots, can solve the problems of not allowing the removal of rail waist corrosion, etc., and achieve the effects of saving manpower and material resources, strong adaptability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

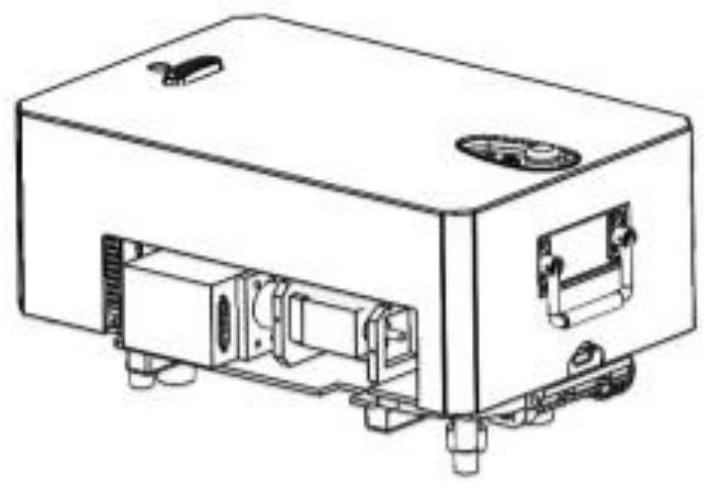

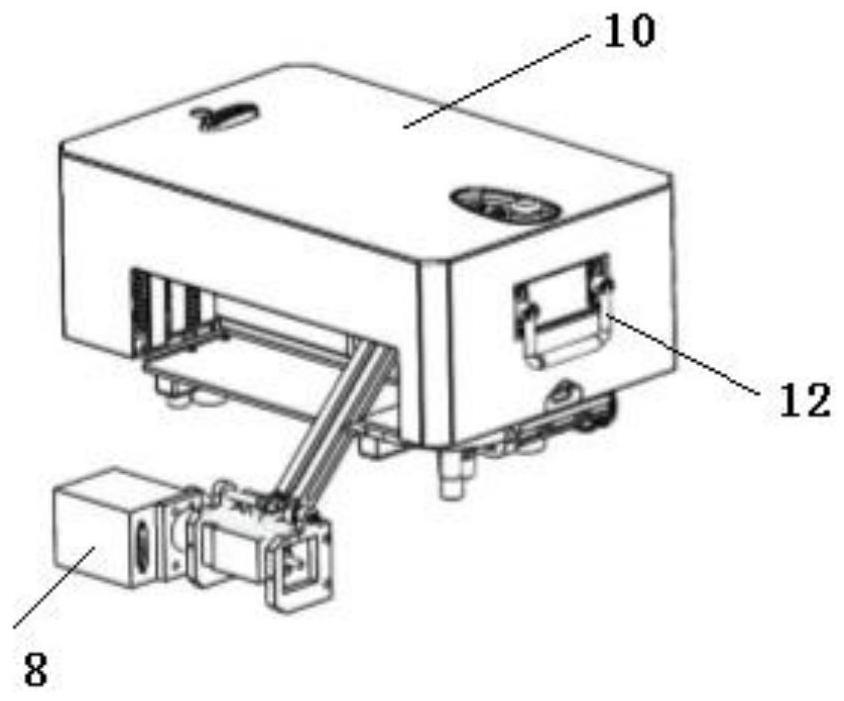

[0038] Such as figure 1 , figure 2 As shown, a rail intelligent laser cleaning robot of the present invention is an automatic special equipment for removing floating rust, grease, water vapor and other pastes on rail waists, and it utilizes a laser cleaning head 8 connected to a laser 9 to emit The high-energy fiber laser with a micron or nanometer wavelength discharges the rail waist to realize the cleaning of the rail waist floating rust, grease, water vapor and other pastes. figure 1 , figure 2 Shown respectively are the laser cleaning head 8 in the working position and the laser cleaning head 8 in the stowed position.

[0039] Track laser cleaning robot of the present invention, its structure is as follows:

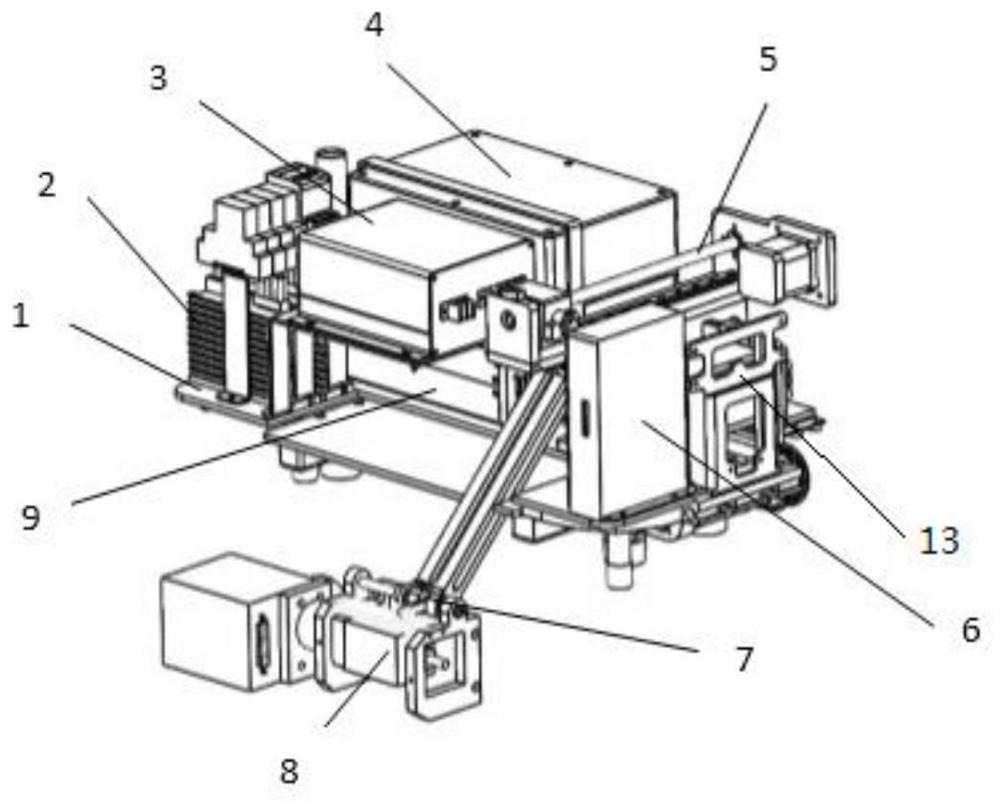

[0040] Such as image 3 , Figure 4 As shown, the track intelligent laser cleaning robot of the present invention is mainly composed of an automatic walking platform 1, a motor drive unit 2, a laser control box 3, a battery 4, an automatic retractable mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com