A rapid adjustment device for asymmetric hydrodynamic axial force of flywheel gap fluid

A hydrodynamic and asymmetric technology, applied in the field of fluid machinery, can solve the problems of time-consuming and laborious, increasing the number of installation and debugging of the test bench, and achieve the effect of optimizing the structure, simplifying the experimental adjustment plan, and controlling the hydrodynamic axial force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

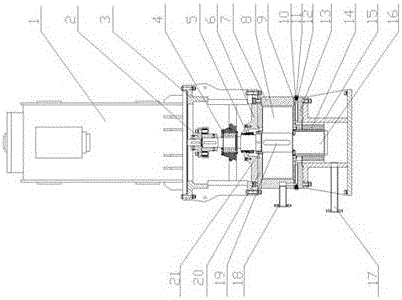

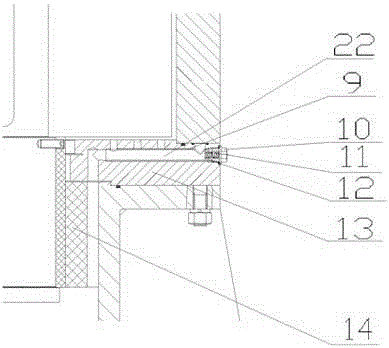

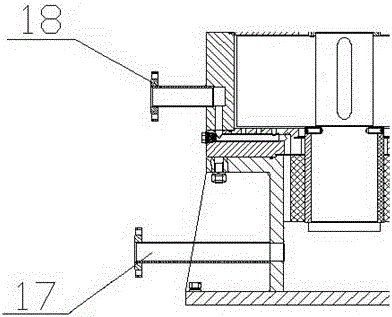

[0025] The flywheel 8 is fixed on the flywheel shaft 16 through the flywheel connecting key 19 and connected by the flywheel fastening nut 21 to form a flywheel rotor assembly. The flywheel rotor assembly is connected with the motor supporting base 3 and the flywheel supporting base 15 through the radial roller bearing 4 and the lower radial bearing 14 respectively. The flywheel casing 7 and the flywheel lower end cover 13 are connected to the flywheel support seat by bolts, the flywheel casing 7, the flywheel upper end cover 20 and the motor support seat connecting plate 6 are connected to the motor support seat 3, and the upper end of the flywheel shaft 16 is sealed with a mechanical seal 5, combined with The use of flywheel support seat 15 forms a closed gap flow channel. The driving motor 1 is connected with the motor support base 3, and connected with the flywheel shaft 16 through the flexible coupling 2, so as to drive the flywheel assembly to run. The return hole sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com