Through-flow turbine corrosion test model device

A technology of tubular water turbine and model device, which is applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as economic loss and corrosion failure of power stations, and achieve the effect of reasonable distribution and optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

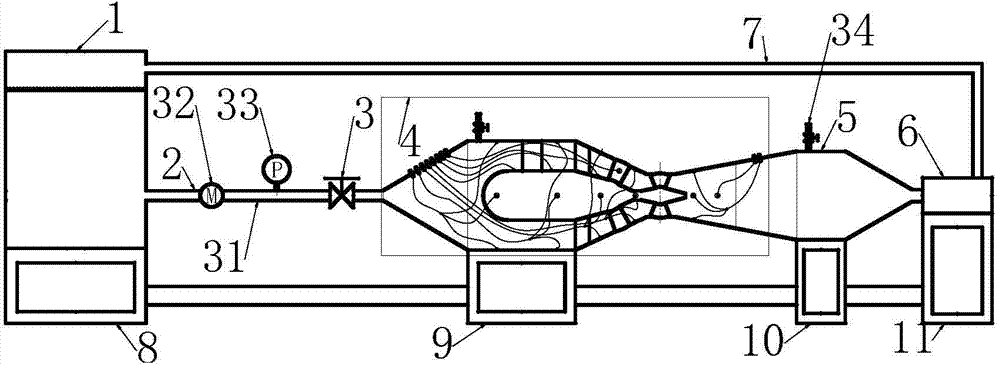

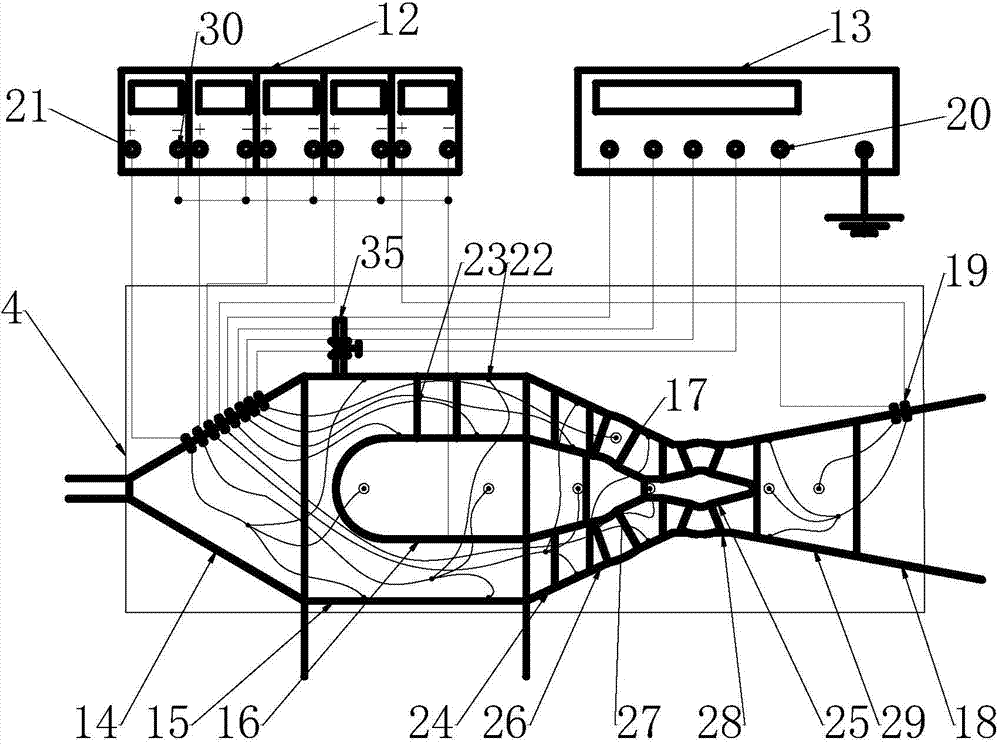

[0010] Such as figure 1 , figure 2 As shown, the tubular turbine corrosion test model device mainly includes: water tank 1, first water inlet pipe 2, flow rate meter 32, second water inlet pipe 31, pressure gauge 33, valve 3, tubular turbine model 4, Drainage tank 5, water pump 6, return pipe 7, water tank support 8, model support 9, drainage tank support 10, water pump support 11, potentiostat 12, digital multimeter 13, conductive electrode with insulating case 19, electrode 22 , the first exhaust valve 34 .

[0011] The first water inlet pipe 2 is welded to the water tank 1, the first water inlet pipe 2 is bolted to the water inlet end of the velocity meter 32, the water outlet end of the flow velocity meter 32 is bolted to the second water inlet pipe 31, and the pressure gauge 33 is welded to the second water inlet pipe 31 connection, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com