Production management system for sand casting enterprise

A production management system, sand casting technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as high dependence on manual management, extensive cost control, and chaotic management control, so as to reduce costs and eliminate management loopholes , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more directly understood by those skilled in the art, and the protection scope of the present invention will be more clearly defined. .

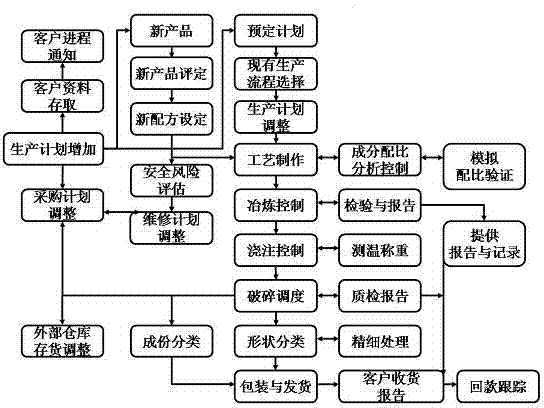

[0030] See figure 1 , The embodiment of the present invention includes:

[0031] A production management system for a sand casting enterprise includes: a sales order module, a casting process simulation module, a mold production module, a sand mold making module, a smelting pouring module, a post-processing module, a packaging and transportation module, and a purchasing and transportation module.

[0032] The sales order module sets standardized templates for new customers and orders, such as setting up detailed order templates for new customers, and directly calling templates for orders from old customers. After data modification based on curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com