Absorbable magnesium alloy staples with antibacterial and anti-inflammatory functions and preparation method thereof

An antibacterial and anti-inflammatory, magnesium alloy technology, applied in medical science, surgery, surgical instruments, etc., can solve the problems of tissue hyperplasia, peeling, non-antibacterial and anti-inflammatory effects, etc., and achieve the effect of slowing down degradation and increasing load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

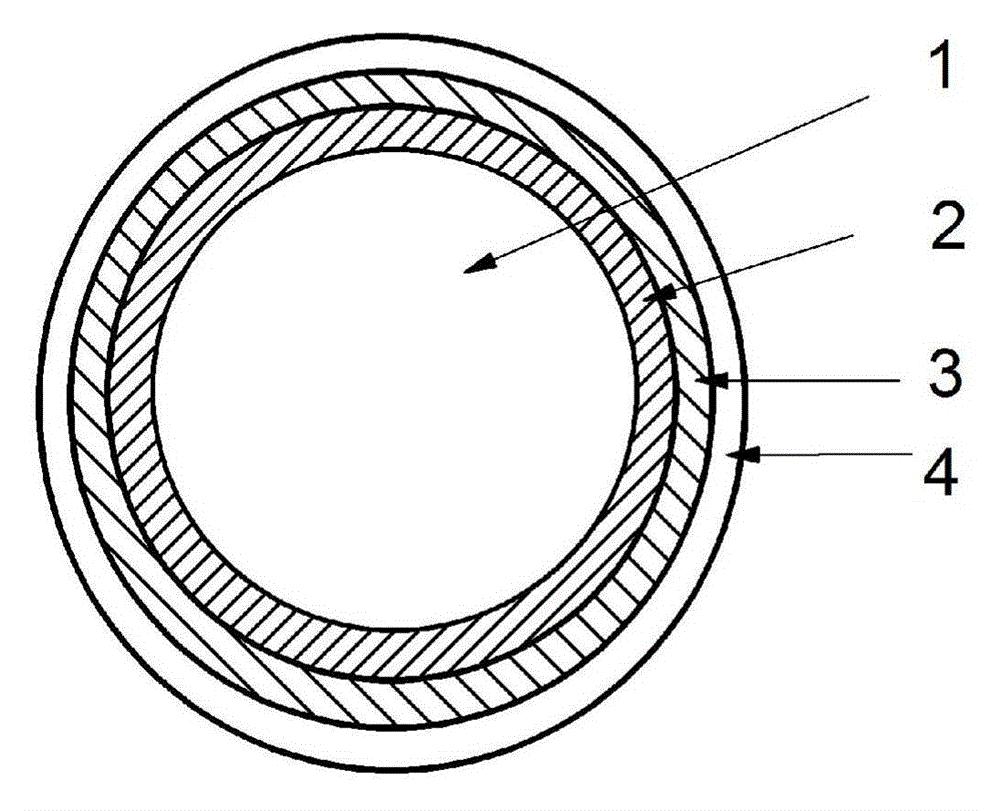

[0030] The absorbable magnesium alloy staple with antibacterial and anti-inflammatory functions of the present invention consists of a core of pure magnesium wire with a porous ceramic layer on the surface, an intermediate layer loaded with ibuprofen anti-inflammatory drugs and copper ions with gelatin as a carrier, and is degradable. The composition of the outer surface layer of polylactic acid, its specific preparation process is as follows:

[0031] 1) Drawing pure magnesium into a wire with a diameter of 0.3mm;

[0032] 2) Perform micro-arc oxidation treatment on the magnesium wire. The main components of the electrolyte are 10g / L sodium silicate, 2g / LNaOH and 8g / L hydroxyapatite nanoparticles, the magnesium wire is immersed in it, and a voltage of 420V is applied for 15 minutes of micro-arc oxidation treatment to make it A layer of porous ceramic layer rich in magnesium oxide, magnesium silicate and hydroxyapatite is formed on the surface in situ. The average micropore s...

Embodiment 2

[0040] Absorbable magnesium alloy staples with antibacterial and anti-inflammatory functions are composed of an AZ31B magnesium alloy wire core with a porous ceramic layer on the surface, a middle layer loaded with nabumetone and copper ions on the gelatin carrier, and an outer surface of degradable polylactic acid. Layer composition, the specific preparation process is as follows:

[0041] 1) AZ31B magnesium alloy is drawn into a wire with a diameter of 0.5mm;

[0042] 2) Phosphating the surface of the magnesium alloy wire, the solution is NH 4 h 2 PO 4 120g / L, (NH 4 ) 2 SO 3 ·H 2 O30g / L, ammoniacal liquor (30%) 6mL / L, generate the porous ceramic layer based on the phosphate of magnesium, the average pore size of ceramic layer is 10 μ m, and average layer thickness is 30 μ m;

[0043] 3) Weigh 5mg of nabumetone and dissolve it in 100ml of dichloromethane solution;

[0044] 4) Dissolve 3g of gelatin in 1L of 80°C distilled water to obtain a gelatin solution, add an app...

Embodiment 3

[0050] The absorbable magnesium alloy staple with antibacterial and anti-inflammatory functions consists of a WE43 magnesium alloy wire core with a porous ceramic layer on the surface, a middle layer loaded with acemetacin and copper ions on the gelatin carrier, and a degradable PLGA surface. Surface composition, its specific preparation process is as follows:

[0051] 1) Drawing WE43 magnesium alloy into a wire with a diameter of 0.5mm;

[0052] 2) Perform micro-arc oxidation treatment on the magnesium wire. The main components of the electrolyte are 10g / L sodium silicate and 2g / LNaOH. The magnesium wire is immersed in it, and a voltage of 380V is applied for 10 minutes of micro-arc oxidation treatment, so that a layer rich in magnesium oxide is formed on the surface in situ. , Magnesium silicate porous ceramic layer, the average micropore size of the ceramic layer is 8 μm, and the average layer thickness is 20 μm;

[0053] 3) Weigh 10 mg of acemetacin and dissolve it in 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com