Multi-station layered iron removal device

A multi-station, layered technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low iron removal efficiency, low degree of automation and work efficiency, and high labor intensity, so as to improve the removal efficiency. The effect of iron efficiency, reducing labor intensity and improving iron removal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

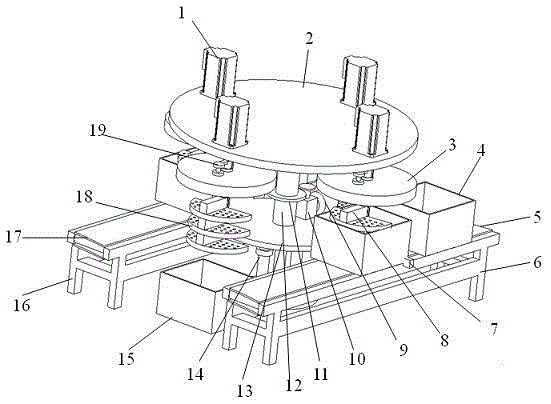

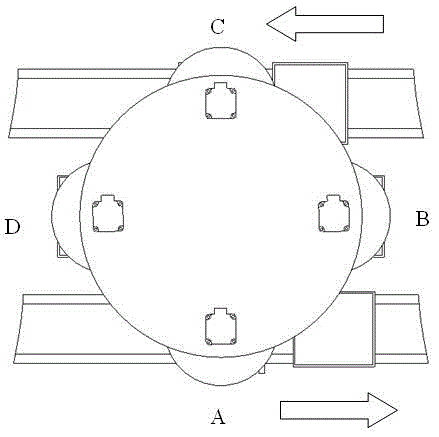

[0018] Such as figure 1 —3. Before the device works, the hydraulic cylinder 14 acts, and its piston rod stretches out to move the entire push plate 13 and all parts on the upper end upward, and make the lowest point of the multilayer magnetic net 18 higher than the slurry pool 4 The highest position, conveyor belt 1 5 and conveyor belt 2 17 will transport the slurry pool 4 to be iron-removed forward, and the slurry pool 4 will stop when it moves to the bottom of the multi-layer magnetic net 18, and the position sensor 7 will ensure its accurate docking , so far the preparatory work before iron removal is completed.

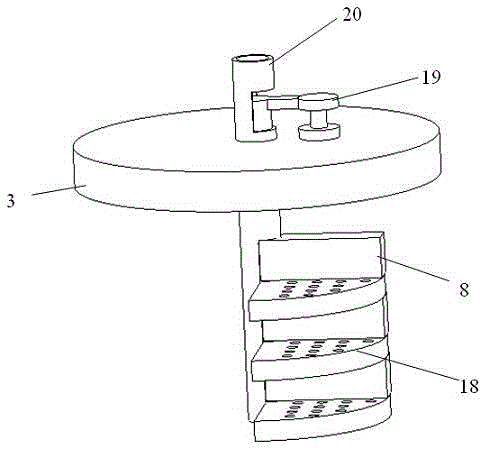

[0019] Then the turntable motor 9 drives the turntable 2 through the reducer 10 to shift to the multilayer magnetic net 18 above the slurry pool 4, the iron removal motor 1 starts, and the iron removal motor 1 drives the suspension plate 3 and the multila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com